Crack deformation monitor

A monitor and deformation technology, applied in the field of measurement, can solve problems such as the measurement function of bending deformation without cracks, and achieve the effect of comprehensive and accurate monitoring and response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

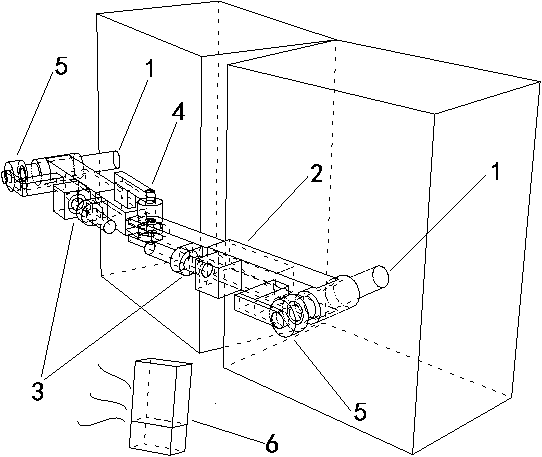

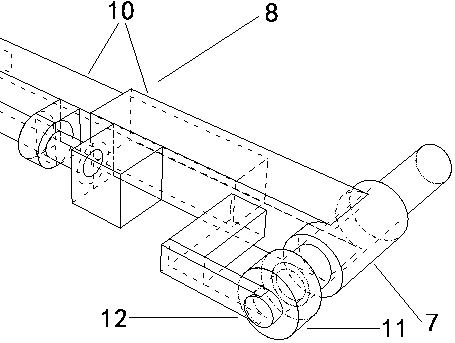

[0020] Such as Figure 1-3 As shown, the crack deformation monitor includes two columns, a measuring rod, a telescopic displacement sensor A, an angle sensor A, an angle sensor B and a data monitoring terminal. The two columns are fixedly installed on the structures on both sides of the crack, and the two columns are perpendicular to their respective structures. Plane, the two ends of the measuring rod are cylinders, the direction of the generatrix of the cylinder is at a certain angle to the measuring rod, the inner diameter of the cylinder is equal to the outer diameter of the column, the two cylinders are set outside the two columns, and one or both sides of the measuring rod have a telescopic structure, and A telescopic displacement sensor A is installed at the telescopic structure, and there is a uniaxial rotation structure in the middle of the measuring rod, and an angle sensor A is installed at the uniaxial rotation structure, and an angle sensor B is installed at the co...

Embodiment 2

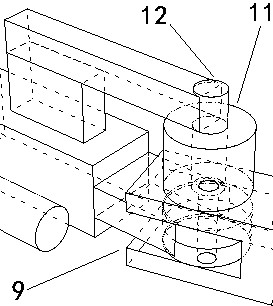

[0026] Such as Figure 4 As shown, on the basis of Embodiment 1, a telescopic displacement sensor B is also included, which is installed on a certain column. The cylinder on the column and the angle sensor B have a space for sliding up and down. The cylinder and the column are fixedly connected, and the cylinder and the angle sensor B on the other column are restricted from sliding up and down. The telescopic displacement sensor B can measure the dislocation of cracks with high precision, and is suitable for the situation where the dislocation of cracks is obvious; if the telescopic displacement sensor B is not installed in Example 1, the dislocation can also be calculated by the deformation of the measuring rod, and is suitable for the situation where the dislocation of cracks is small. The telescopic displacement sensor may be a magnetostrictive displacement gauge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com