A monitor with the function of crack bending deformation measurement

A monitor and deformation technology, applied in the field of measurement, can solve problems such as bending deformation measurement function without cracks, and achieve the direct effect of measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

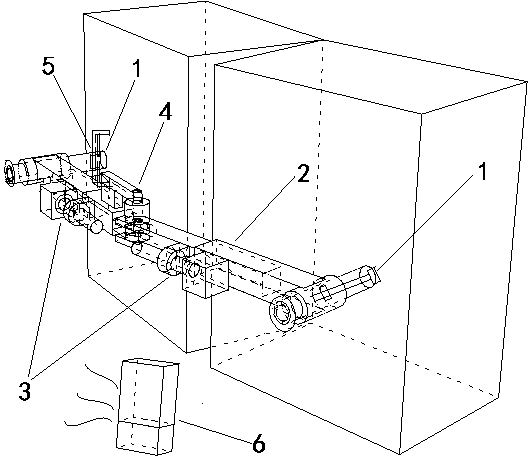

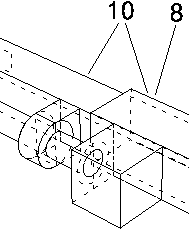

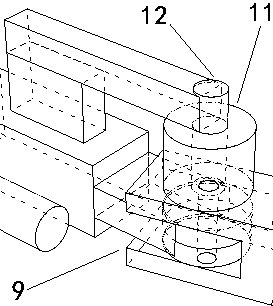

[0020] Such as Figure 1-5 As shown, a monitor with crack bending deformation measurement function includes two columns, a measuring rod, a telescopic displacement sensor A, an angle sensor, a telescopic displacement sensor B, a telescopic displacement sensor C and a data monitoring terminal. The two columns are installed on the crack On both sides of the structure, the two columns are perpendicular to their respective structural planes, the two ends of the measuring rod are cylinders, the direction of the generatrix of the cylinder is at a certain angle to the measuring rod, the inner diameter of the cylinder is equal to the outer diameter of the column, and the two cylinders are set outside the two columns The two sides of the measuring rod have telescopic structures respectively, and a telescopic displacement sensor A is installed at the telescopic structure. There is a single-axis rotating structure in the middle of the measuring rod, and an angle sensor is installed at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com