Slideway-type insulation telescoping work ladder

A working ladder and slideway-type technology, which is applied to ladders, buildings, building structures, etc., can solve problems such as danger, difficulty in fixing the feet of the working ladder, and falling from high altitudes, so as to ensure personal safety and work conveniently and quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

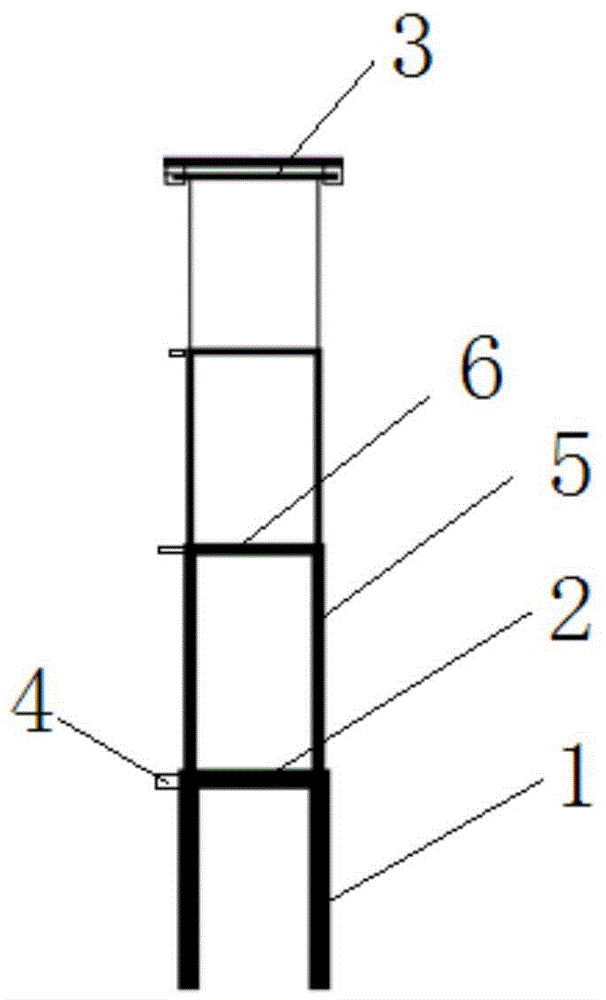

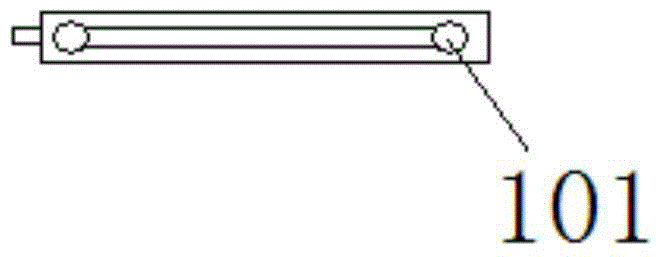

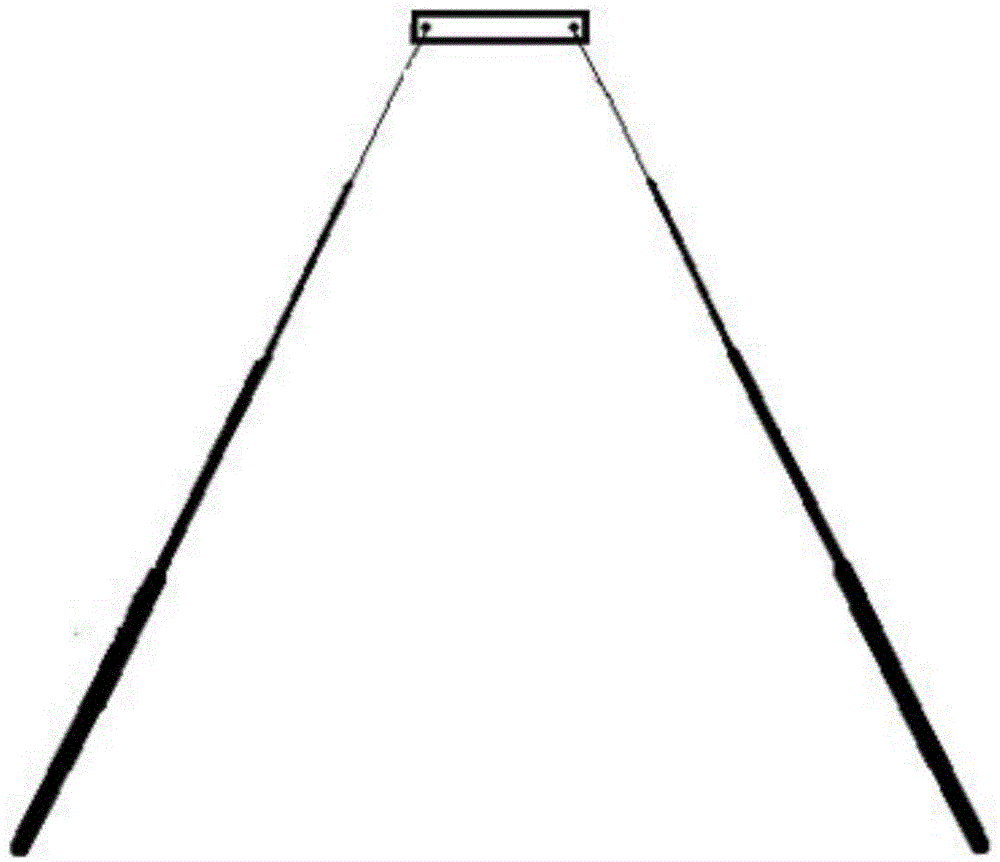

[0016] This embodiment provides a slideway type insulated telescopic working ladder, which is characterized in that: the slideway type insulated telescopic working ladder includes a basic ladder frame 1, a basic cross bar 2, a top connecting frame 3, a positioning pin 4, Telescopic ladder frame 5, telescopic cross bar 6;

[0017] Among them: the basic ladder frame 1 and the basic cross bar 2 are vertically fixedly connected; the telescopic ladder frame 5 and the telescopic cross bar 6 are vertically fixedly connected; the telescopic ladder frame 5 can be inserted into the oval hole 101 of the basic ladder frame 1, and the positioning is realized by the positioning pin 4 The telescopic ladder frame 5 and the telescopic cross bar 6 are 2 groups; the two ends of the top connecting frame 3 are connected to the top of the uppermost telescopic ladder frame 5; the number of the basic ladder frame 1 is 2 groups.

[0018] The basic ladder frame 1, the basic cross bar 2 and the top conn...

Embodiment 2

[0022] This embodiment provides a slideway type insulated telescopic working ladder, which is characterized in that: the slideway type insulated telescopic working ladder includes a basic ladder frame 1, a basic cross bar 2, a top connecting frame 3, a positioning pin 4, Telescopic ladder frame 5, telescopic cross bar 6;

[0023] Among them: the basic ladder frame 1 and the basic cross bar 2 are vertically fixedly connected; the telescopic ladder frame 5 and the telescopic cross bar 6 are vertically fixedly connected; the telescopic ladder frame 5 can be inserted into the oval hole 101 of the basic ladder frame 1, and the positioning is realized by the positioning pin 4 The telescopic ladder frame 5 and the telescopic cross bar 6 are 4 groups; the two ends of the top connecting frame 3 are connected to the top of the uppermost telescopic ladder frame 5; the number of the basic ladder frame 1 is 2 groups.

[0024] The basic ladder frame 1, the basic cross bar 2 and the top conn...

Embodiment 3

[0028] This embodiment provides a slideway type insulated telescopic working ladder, which is characterized in that: the slideway type insulated telescopic working ladder includes a basic ladder frame 1, a basic cross bar 2, a top connecting frame 3, a positioning pin 4, Telescopic ladder frame 5, telescopic cross bar 6;

[0029] Among them: the basic ladder frame 1 and the basic cross bar 2 are vertically fixedly connected; the telescopic ladder frame 5 and the telescopic cross bar 6 are vertically fixedly connected; the telescopic ladder frame 5 can be inserted into the oval hole 101 of the basic ladder frame 1, and the positioning is realized by the positioning pin 4 The telescopic ladder frame 5 and the telescopic cross bar 6 are 8 groups; the two ends of the top connecting frame 3 are connected to the top of the uppermost telescopic ladder frame 5; the number of the basic ladder frame 1 is 2 groups.

[0030] The basic ladder frame 1, the basic cross bar 2 and the top conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com