Earthquake-proof grooveless coupling

A technology of pipe joints and grooved pipes, which is applied in the field of pipe joints, can solve the problems of difficult assembly operations, prolonged operation time, and obstruction of fluid flow, etc., and achieve the effect of good fluid flow and simple operation procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

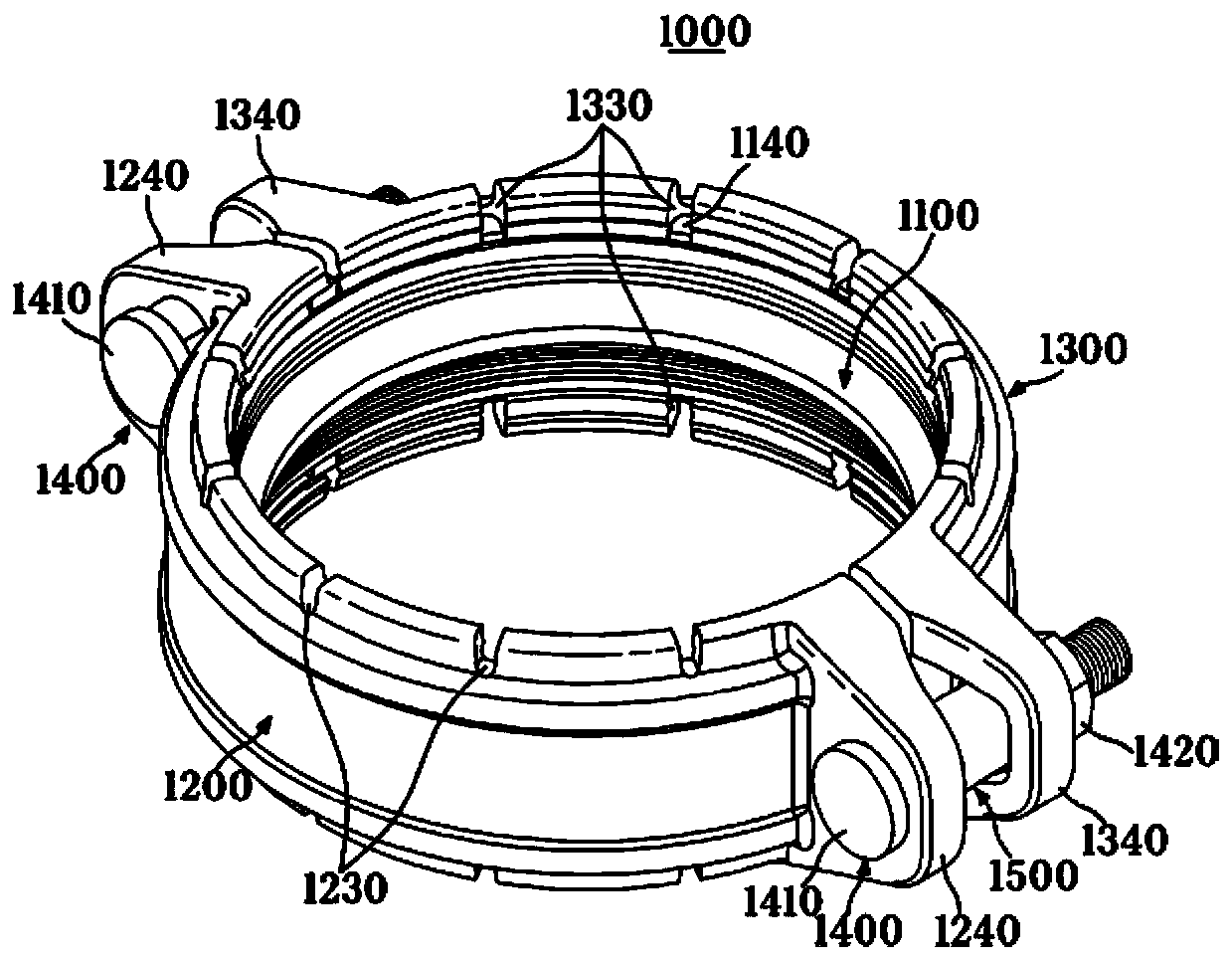

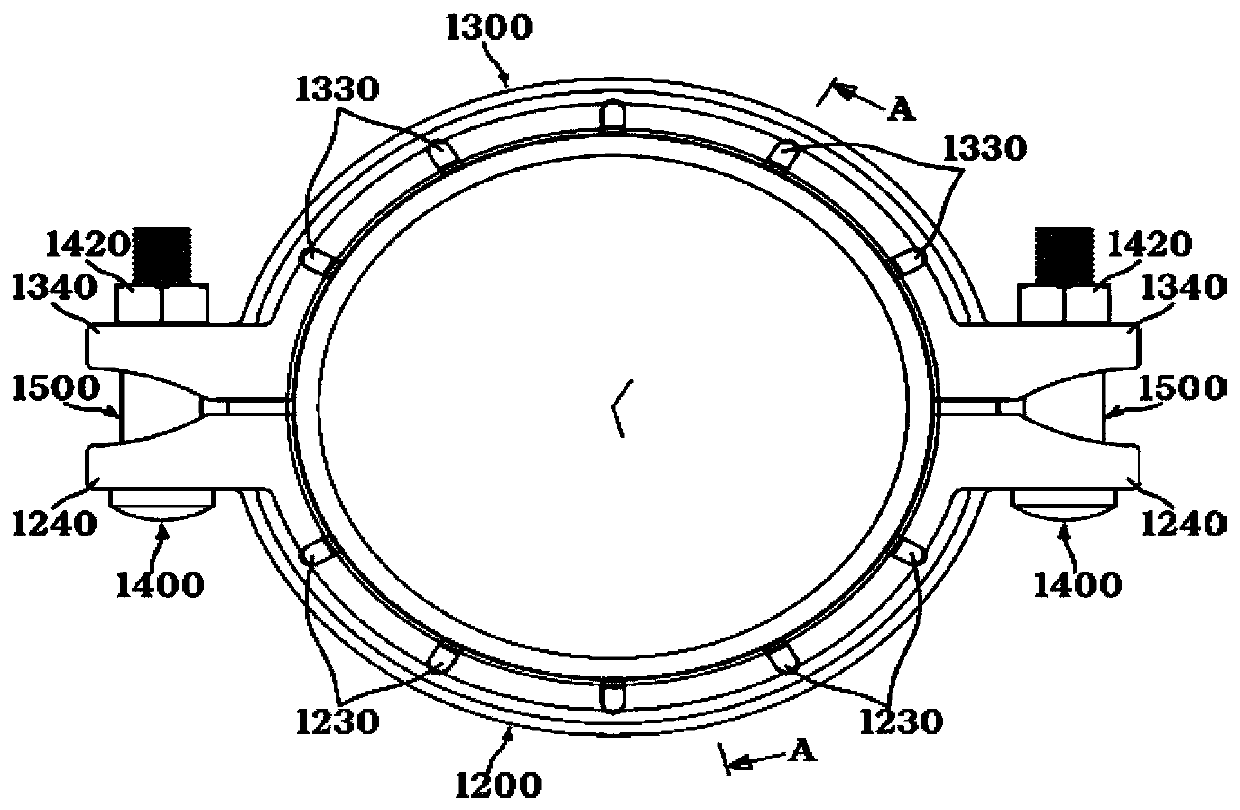

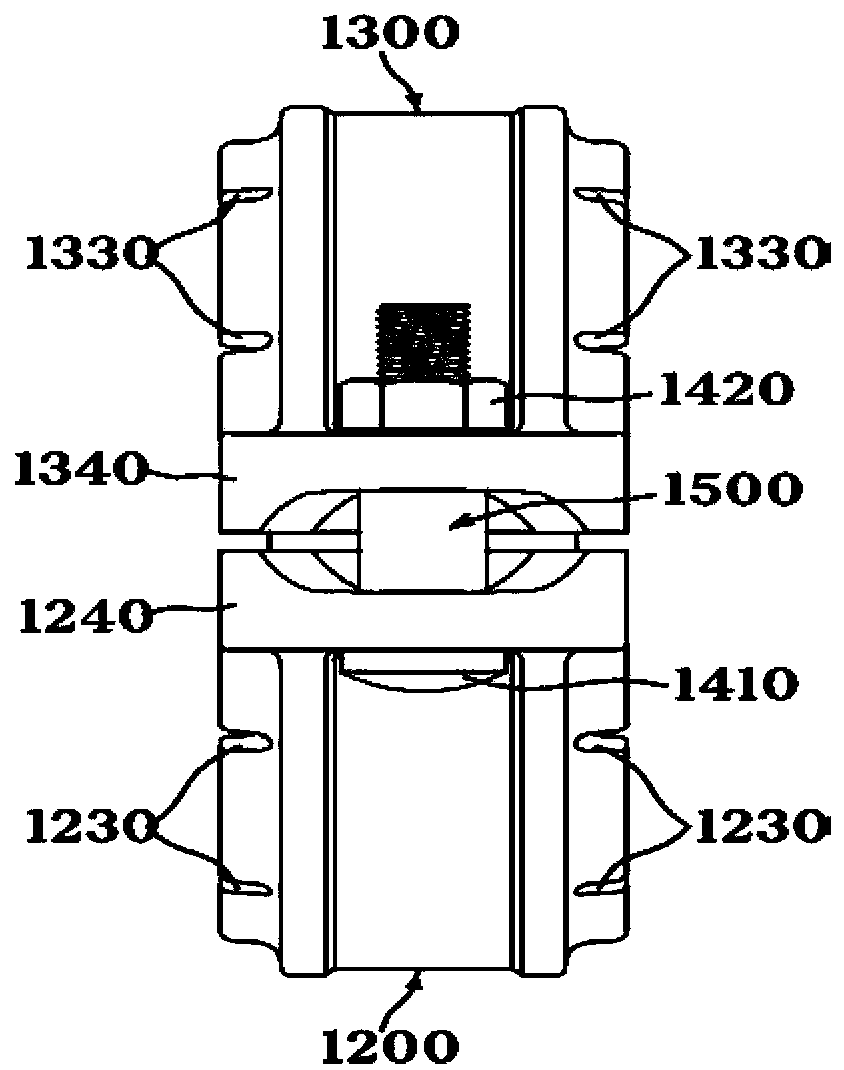

[0065] The vibration-resistant grooveless pipe joint of the embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

[0066] When adding reference signs to multiple components of the above-mentioned drawings, even if the same component is marked on different drawings, the same symbol should be used as far as possible. For known functions that are considered to obscure the gist of the present invention and structures are not specified. Directional terms such as "upper", "lower", "front", "rear", "front end", "front", "rear end" are used for orientation in many of the drawings. The constituent elements of the embodiments of the present invention can be positioned in various orientations, so the terminology of directions is only an example, not a limitation.

[0067] The vibration-resistant grooveless pipe joint 1000 of the first embodiment of the present invention is as Figure 1 to Figure 9 As shown, it includes: an e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com