Injection valve and adhesive dispensing system with same

A jet valve and valve body technology, applied in the field of dispensing valves, can solve the problems of inability to fine-tune glue fluid before spraying, troublesome use of supporting equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

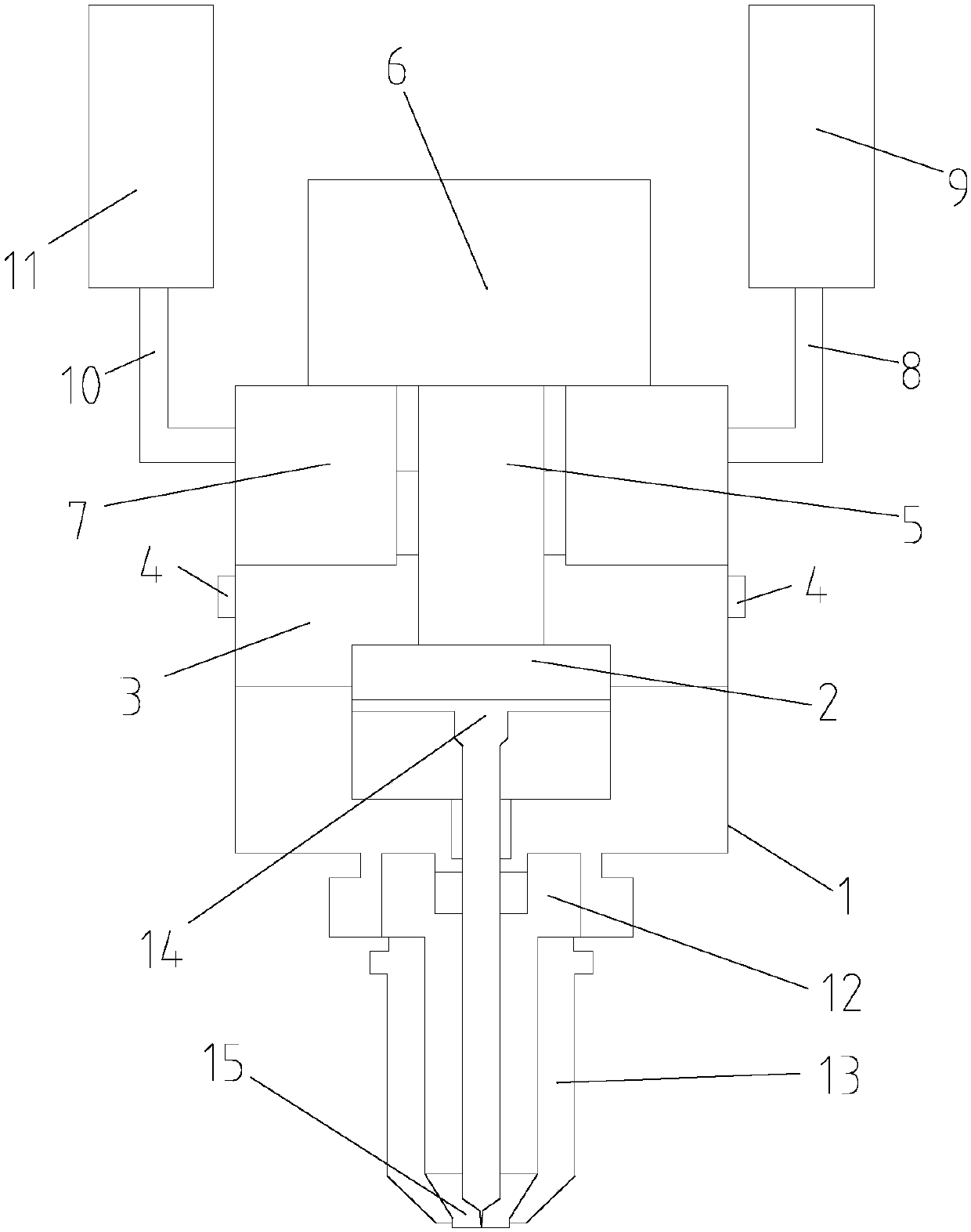

[0016] See attached figure 1 As shown, a jet valve in this embodiment includes a valve body 1, a cavity for accommodating glue is formed in the valve body 1, and a cavity corresponding to the cavity is opened on the side wall of the valve body 1. The valve body 1 is formed with a glue outlet 15 communicating with the cavity, and the cavity is divided up and down with a first chamber 7, a second chamber 3 and a third chamber 14 , the third chamber 14 communicates with the glue nozzle 15; the third chamber 14 is provided with a piston 2, and the edge of the piston 2 is attached to the inner wall of the third chamber 14; The top of the piston 2 is connected with one end of the adjustment rod 5, and the other end of the adjustment rod 5 penetrates upwards through the second chamber 3, and the first chamber 7 is connected with the drive cylinder 6 outside the valve body 1; A first flow channel is provided between the chamber 3 and the third chamber 14, and a blocking portion capab...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap