Rubber shock insulation cushion for monitoring interface peeling and system for monitoring interface peeling thereof

A technology of rubber vibration isolation pads and interface peeling, which is applied to measuring devices, instruments, and mechanical devices, etc., can solve problems such as non-monitoring, improve safety, reduce monitoring and operation and maintenance costs, and reduce hidden safety hazards and operation risks. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to more clearly illustrate the embodiments of the present invention and / or the technical solutions in the prior art, the specific implementation manners of the present invention will be described below with reference to the accompanying drawings. Obviously, the drawings in the following description are only embodiments of the present invention, and those skilled in the art can also obtain other drawings based on these drawings and obtain other implementation.

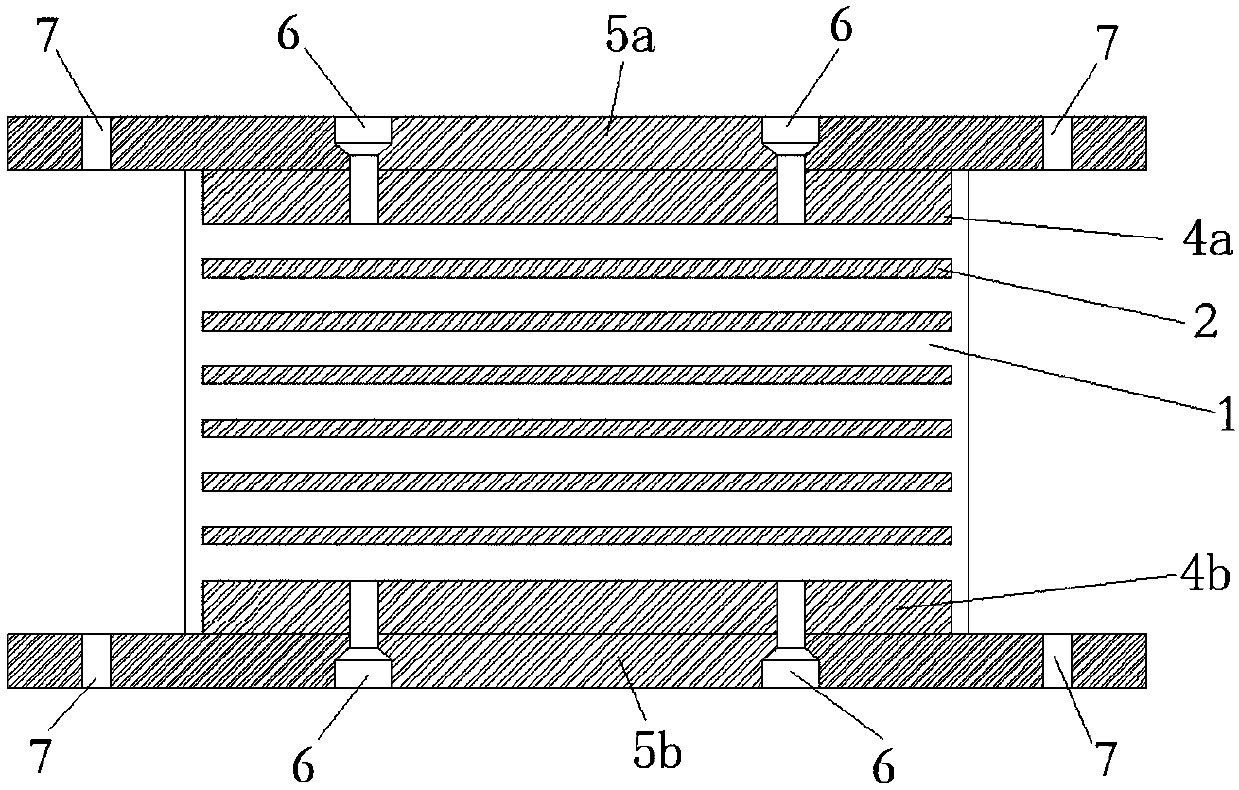

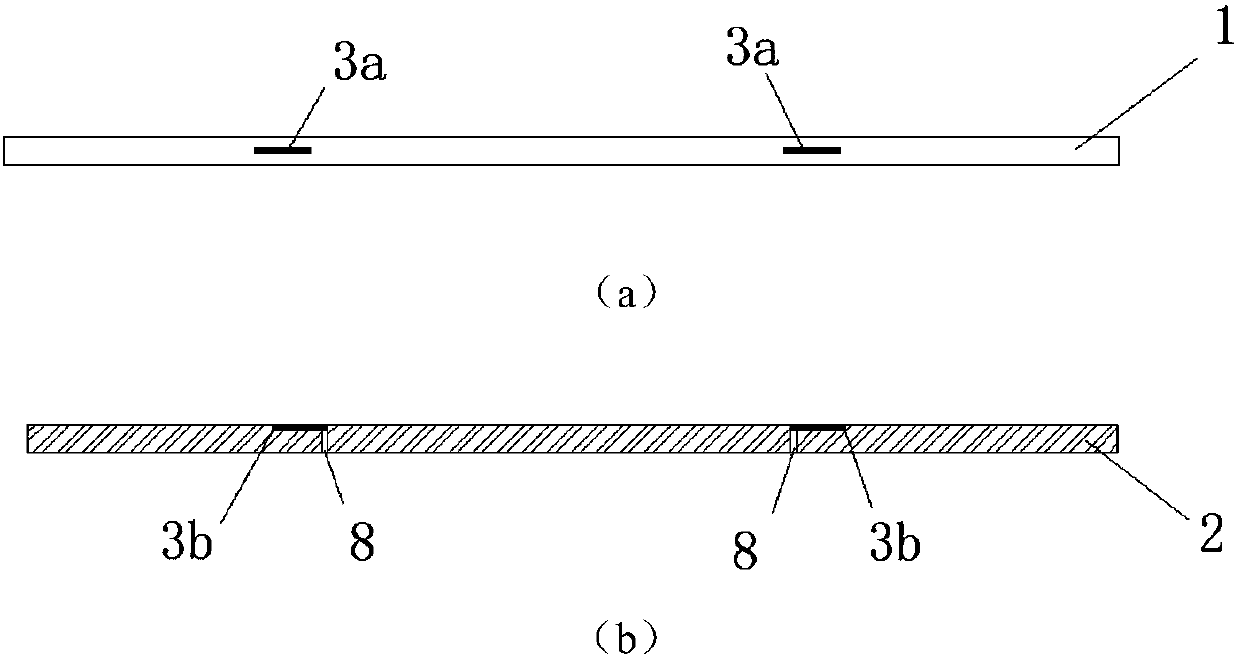

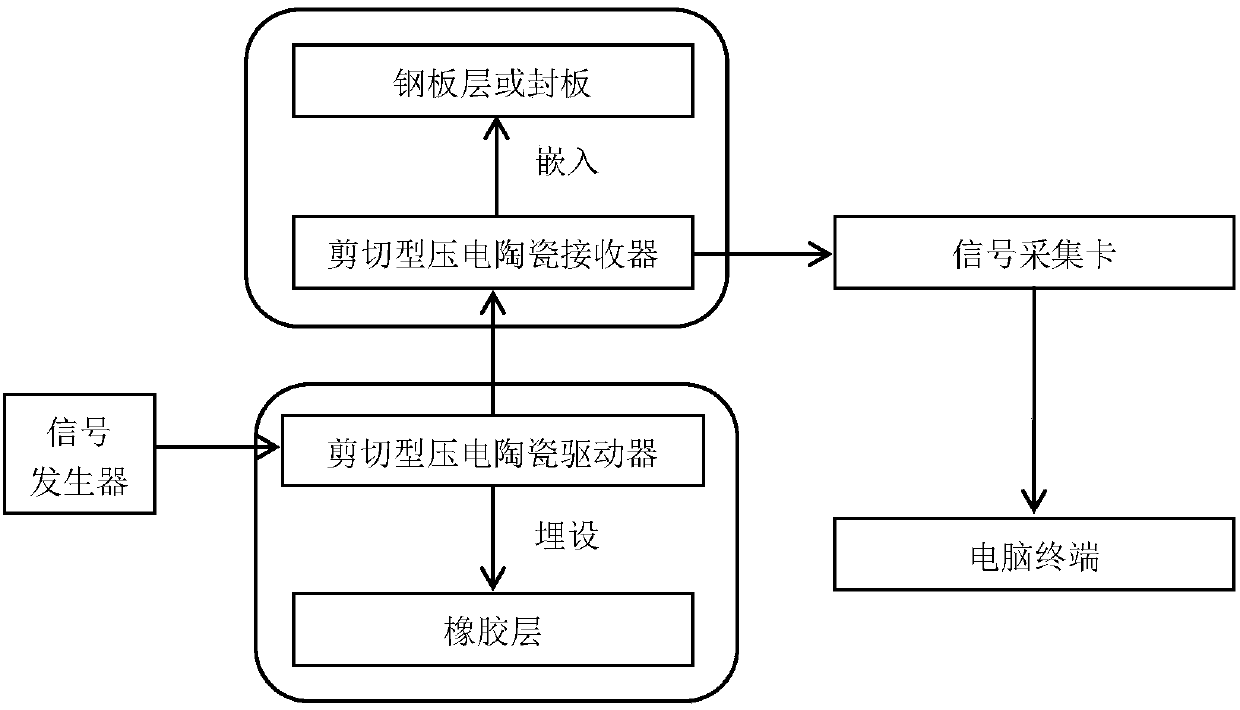

[0041] Figure 1~2 Shown is a specific structure of the rubber shock-isolating pad of the present invention, which includes several layers of rubber layers 1, several layers of steel plate layers 2, several shear-type piezoelectric ceramic drivers 3a, and shear-type piezoelectric ceramic The driver 3a corresponds to several shear-type piezoelectric ceramic receivers 3b, an upper sealing plate 4a, a lower sealing plate 4b, an upper connecting plate 5a, and a lower connecting plate 5b. The plurality of rub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com