An automatic cleaning and spraying device for the outer wall of a storage tank

A spraying device and automatic cleaning technology, which is applied in the direction of spraying devices, cleaning hollow objects, cleaning methods and appliances, etc., can solve the problems of falling casualties, achieve strong adaptability and improve safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

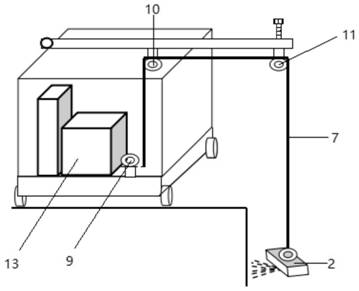

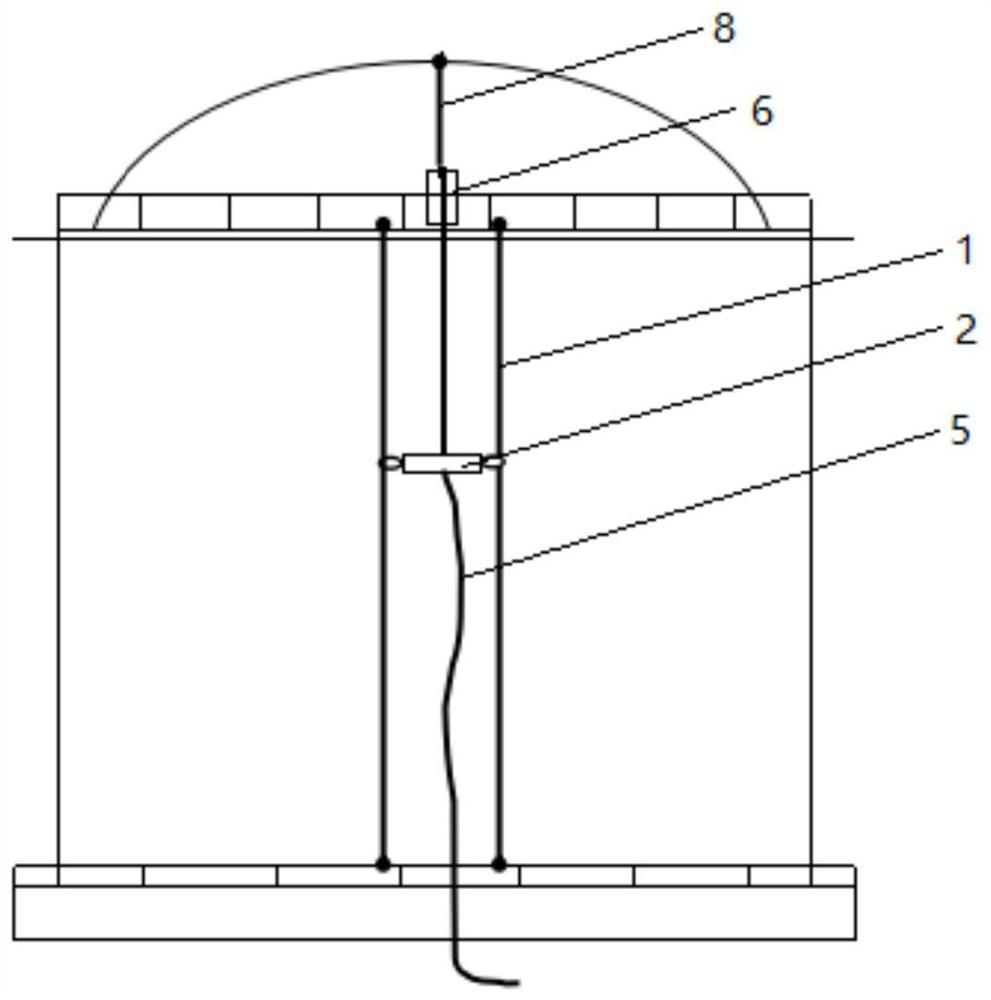

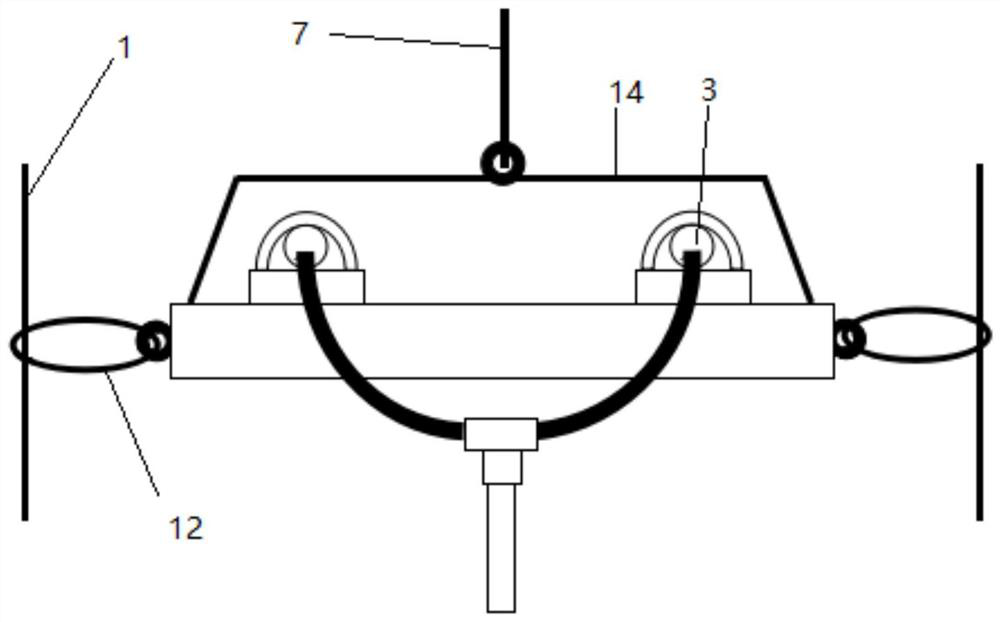

[0021] refer to Figure 1 ~ Figure 3 , the present invention is an automatic cleaning and spraying device for the outer wall of a storage tank, which includes a lifting guide rail 1 vertically arranged on the outer wall of the storage tank, and a cleaning and spraying device 2 slidingly connected with the lifting guide rail 1. The cleaning and spraying device 2 is provided with A plurality of nozzles 3, the cleaning and spraying device 2 are connected to the driving device, and each nozzle 3 is connected to the feeding pipe 5 for conveying the cleaning liquid. The feeding pipe 5 is a pressure-resistant hose, one end is connected to the nozzle 3, and the other end is connected to high-pressure water equipment or an airless sprayer, and the spray liquid pressurized by the equipment is delivered to the nozzle 3.

[0022] Each nozzle 3 has one or more nozzles. The number and aperture are determined according to the characteristics of the spray material and the required flow, press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com