Environmental friendly energy-saving spraying type liquid phase plasma rust and stain removal and surface modification method

A liquid plasma ionization, environmental protection and energy-saving technology, which is applied in the field of ion rust removal and surface modification, can solve the problems that biological cleaning technology is in the research and development stage, and achieve the effects of reducing damage, reducing stress concentration, and increasing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

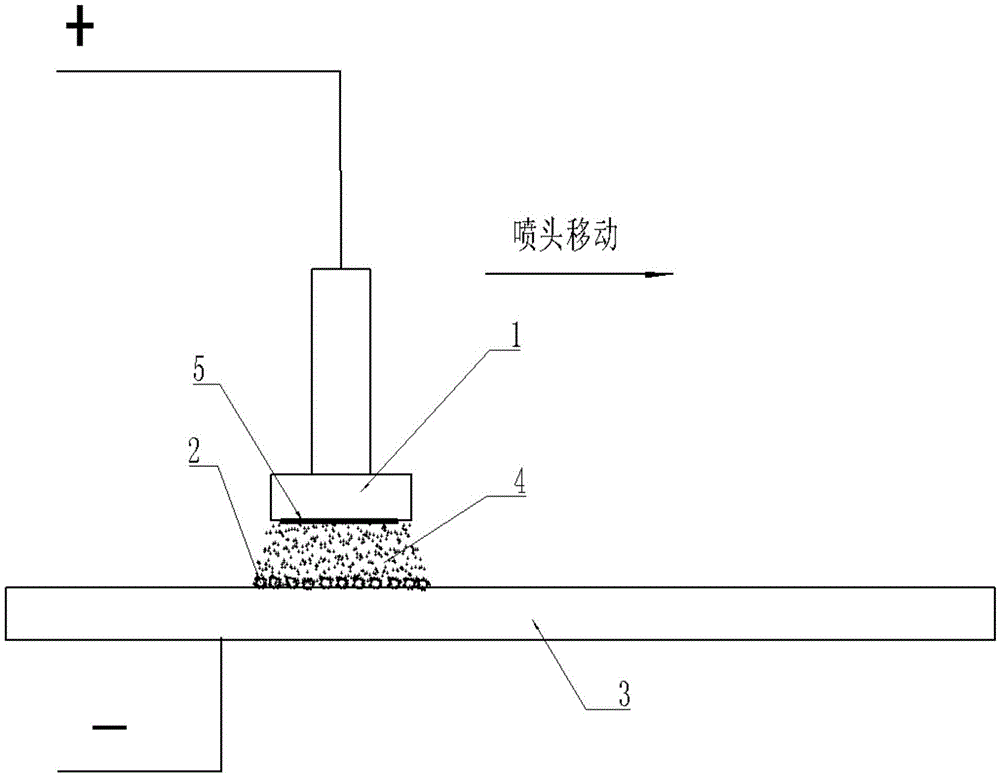

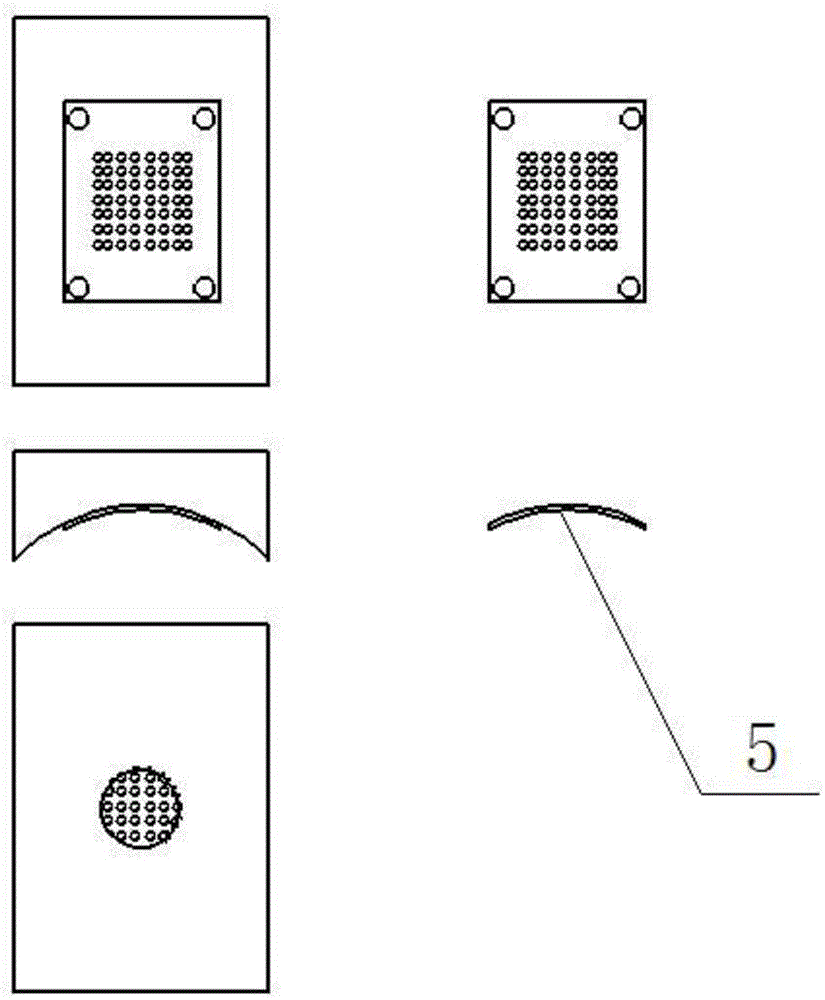

[0025] Such as figure 1 As shown, it is a schematic diagram of spraying liquid plasma ion cleaning liquid, the cathode (or anode) of the power supply is connected to the workpiece 3 to be cleaned, and the other pole of the power supply is connected to the nozzle 1 (see figure 1 , the base material is made of titanium plate, carbon plate or stainless steel plate), and the liquid phase ion cleaning solution 4 ejected from the nozzle 1 is a neutral salt solution based on sodium bicarbonate, sodium carbonate and sodium sulfate. It is 5% sodium bicarbonate, 3% sodium carbonate, and 3% sodium sulfate (mass concentration, the same below). The nozzle 1 is connected with the air compressor, which can accelerate the ejection of the liquid and bring huge impact force. The injection pressure ≥1MPa; the ejected liquid flow directly contacts the workpiece 3 to be cleaned under the action of an appropriate electric field, and plasma 2 is generated on the surface of the workpiece 3, and the...

Embodiment 2

[0027] The difference from Example 1 is that zirconia ceramic particles with a diameter of 0.001-2.0 mm are doped with a mass fraction of 5% in the liquid plasma cleaning solution.

Embodiment 3

[0029] The difference from Example 1 is: the content of the liquid phase ion cleaning solution is 15% sodium bicarbonate, 1% sodium carbonate, and 2% sodium sulfate. And doping quartz sand particles with a diameter of 0.001-2.0mm in the liquid plasma ion cleaning solution with a mass fraction of 3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com