Safety valve and high-pressure pipeline

A technology for safety valves and pipelines, which is applied in the direction of safety valves, valve details, balance valves, etc., can solve the problems of complicated operation, not simple enough and convenient, and achieve the effect of complicated operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

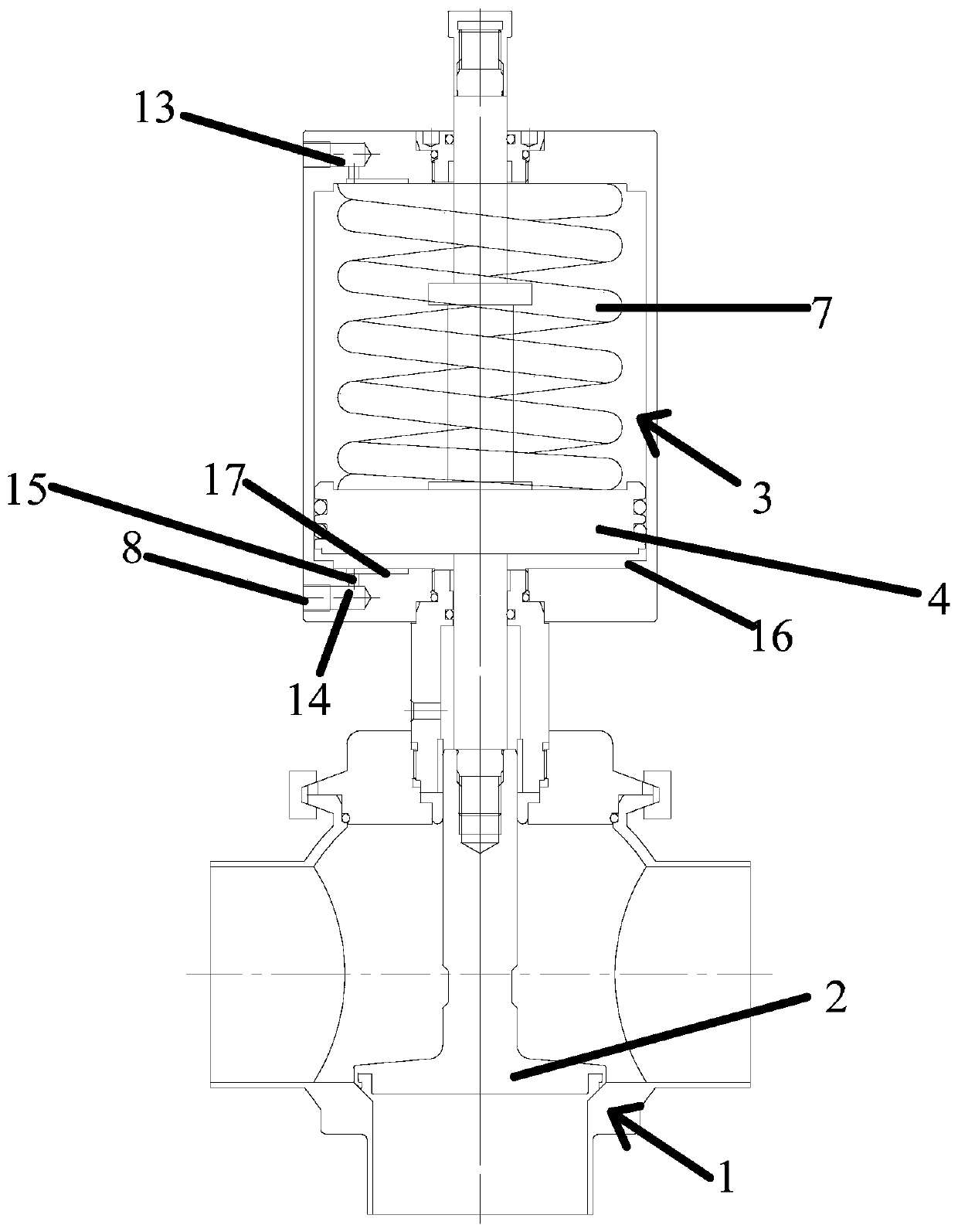

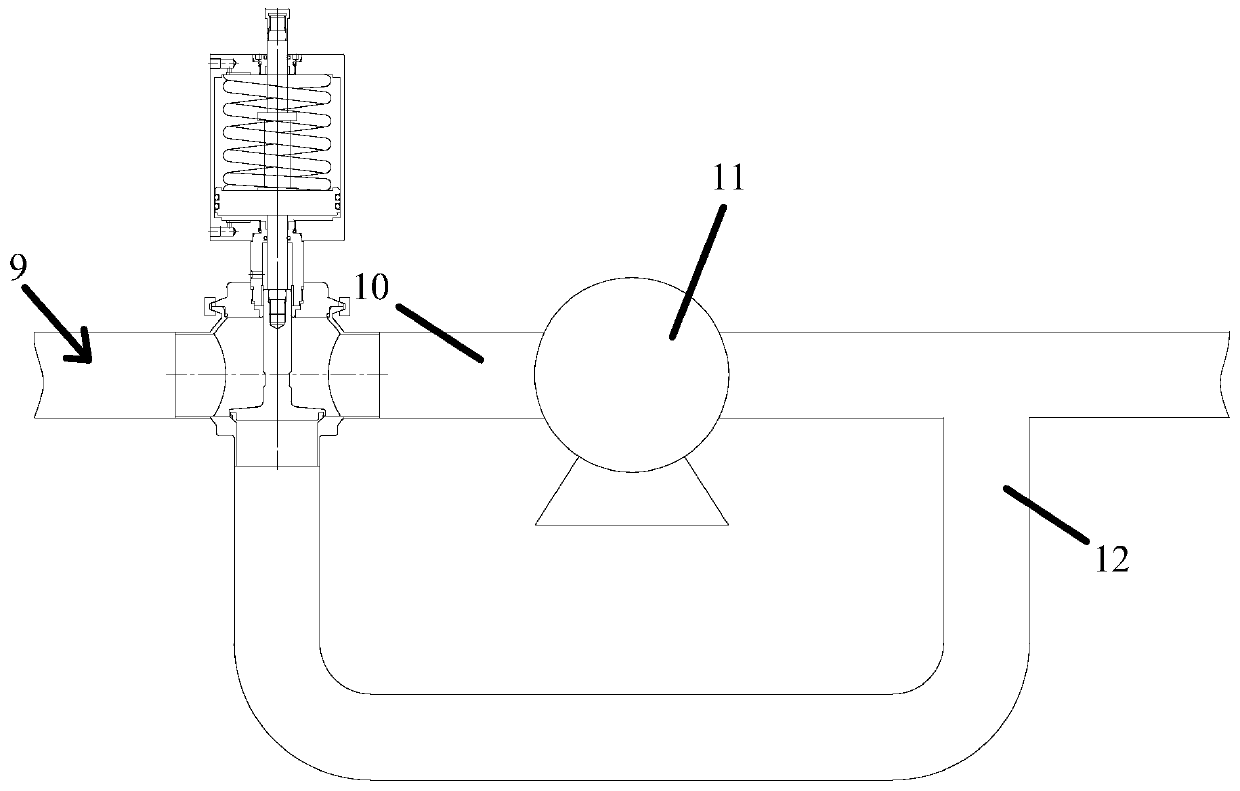

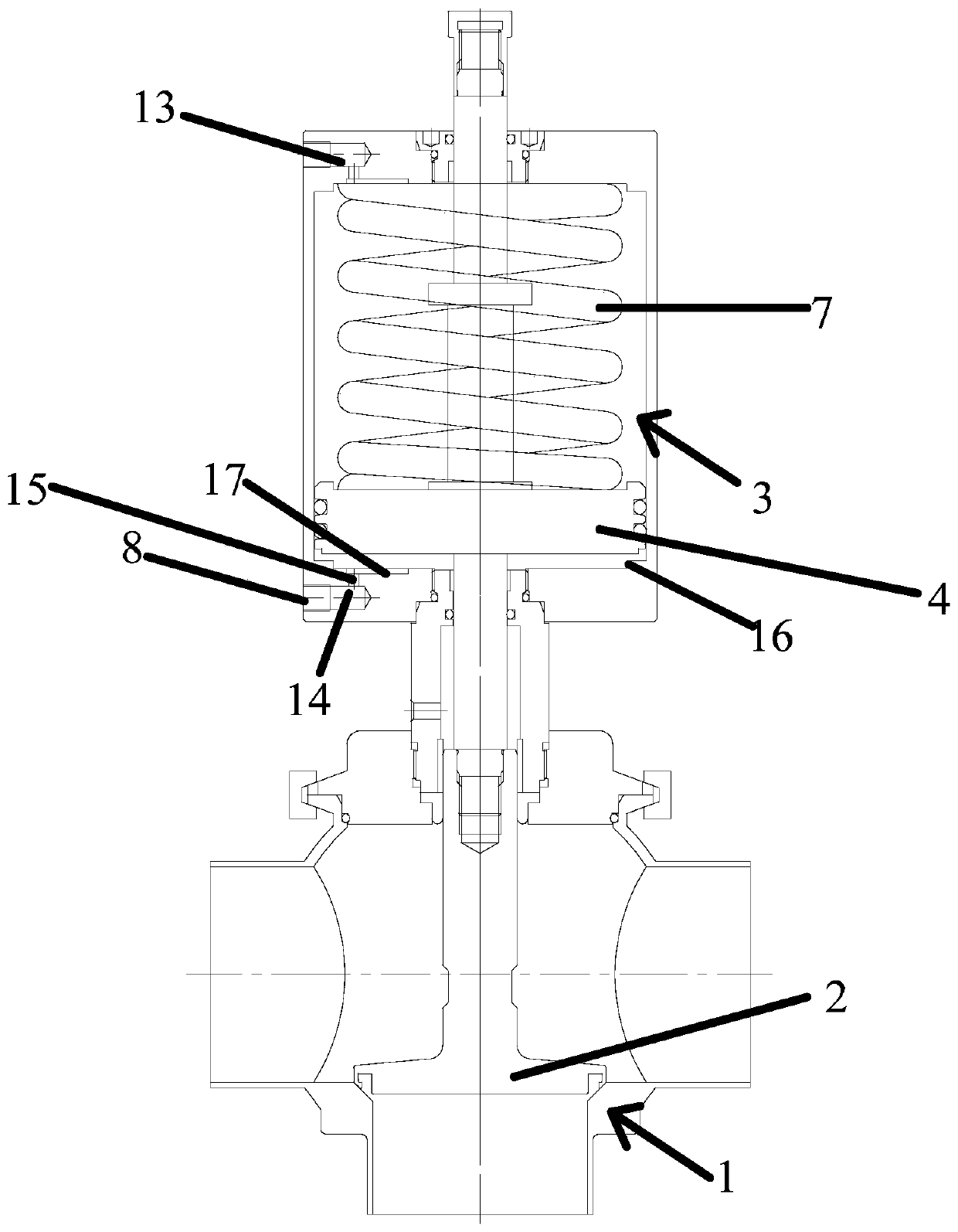

[0034] A safety valve is provided in this embodiment, including: figure 1 As shown, the valve body 1; the valve body 1 is provided with a valve core 2; the cylinder 3 is set corresponding to the valve body 1; the moving piston 4 is set in the cylinder 3 and connected with the valve core 2 The drive member 5 passes the drive medium into the cylinder 3 through the first air inlet 8 to drive the moving piston 4 to move away from the valve body 1; the spool of the safety valve in the prior art passes through the distribution The gravity of the weight is used to ensure the air pressure balance between the pump inlet and the pump outlet. Since the weight of the counterweight cannot be changed, the pressure that can open the safety valve spool is also fixed. Therefore, due to customer needs, in the pipeline Before changing the fluid medium, when the pressure in the pipeline is lower than the take-off pressure of the safety valve, the valve core can be lifted up to clean the pipeline,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com