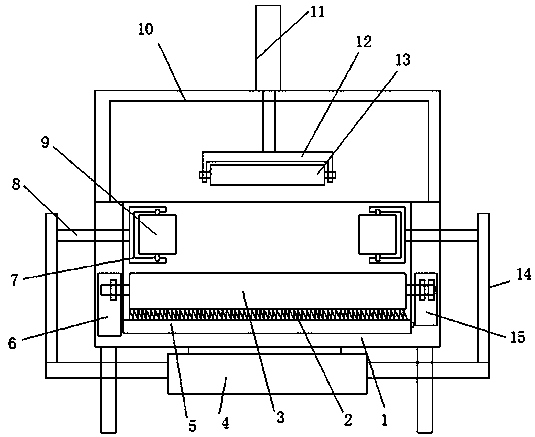

Heavy type duplex chain roller conveyor

A technology of roller conveyors and double chains, which is applied in the direction of conveyor objects, transportation and packaging, cleaning devices, etc., and can solve problems such as collisions, easy dumping of objects, and damage to objects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

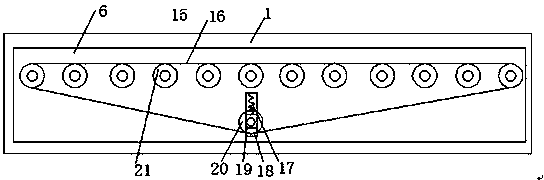

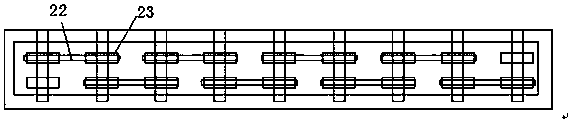

[0017] Embodiment: the material is placed on the transmission roller 3 in the housing 1, the drive motor drives a transmission roller 3 to move, the transmission roller 3 drives the first transmission gear 21 and the second transmission gear 23 at its two ends to rotate, the first transmission gear 21 and the second transmission gear 23 rotate through the first transmission chain 16 and the second transmission chain 22 to drive all the transmission rollers 3 to rotate, and to drive the material transmission. 20 to move downwards to prevent the first transmission chain 16 from loosening after a long period of movement. The double-headed cylinder 4 drives the two movable plates 14 to move to the side close to each other. The movable plate 14 drives the movable frame 7 and the first guide through the connecting rod 8 The rollers 9 move to the side close to each other, and the article is slidably connected with the first guide roller 9 to play a position-limiting role. At the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com