recyclable bolt

A bolt and hollow technology, which is applied in the field of recyclable bolts, can solve the technical defects of recyclable bolts, affect the secondary use, and the bolt cannot be recycled, etc., and achieve the convenience of anchoring construction and retraction construction, and the ultimate resistance Large pulling capacity and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

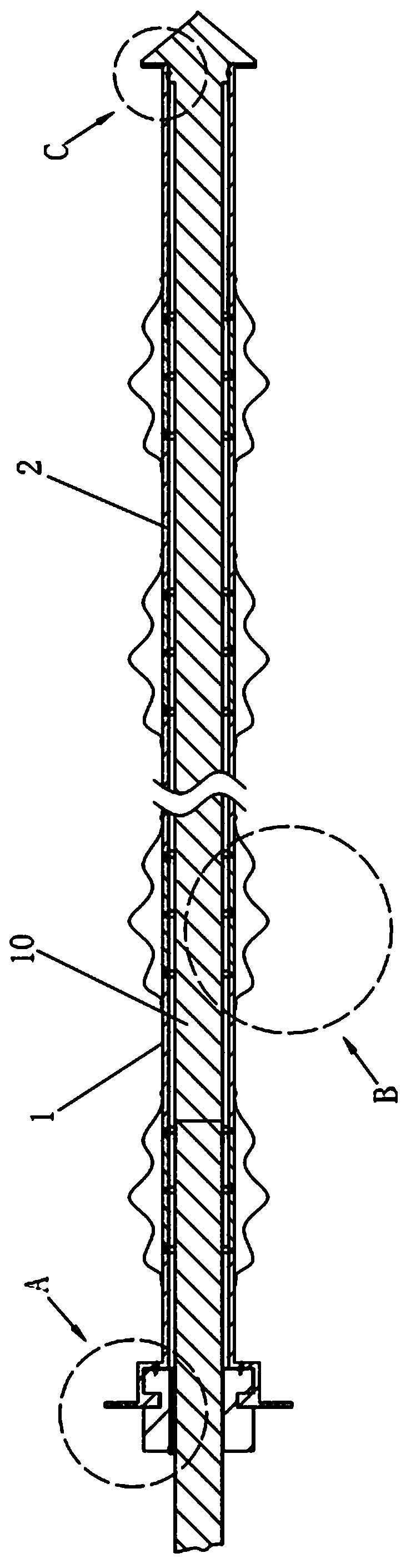

[0054] Such as Figure 1-6 As shown, a kind of recoverable bolt provided in this embodiment comprises:

[0055] A hollow anchor rod 1, the hollow anchor rod 1 includes:

[0056] At least two first anchor sections 2, the first anchor sections 2 are arranged in a straight line, and the axes coincide, and one

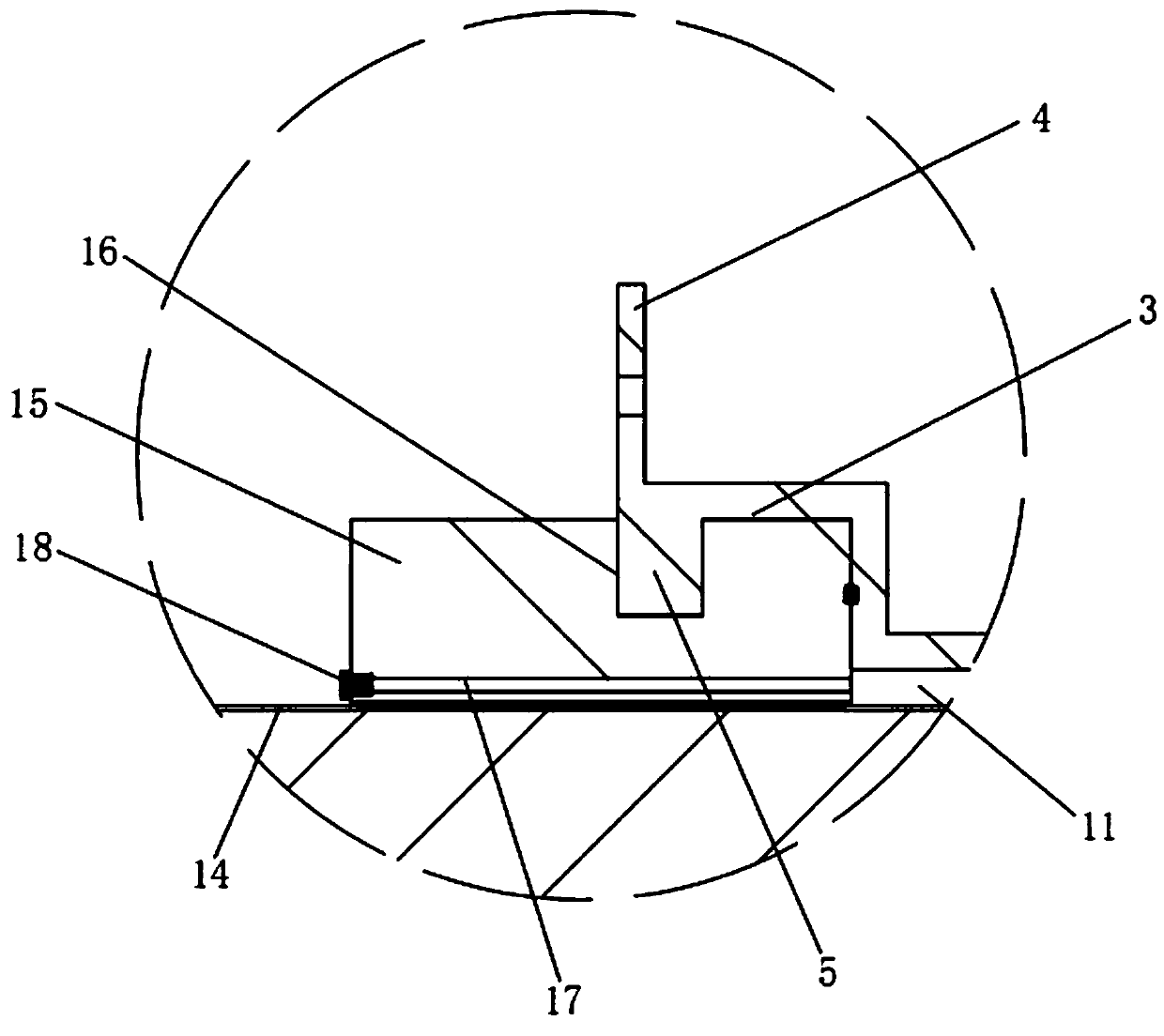

[0057] The end of the first anchor section 2 on one side is provided with a reaming section 3, such as figure 2 and Figure 5 As shown, the outer wall of the reaming section 3 is provided with a first extension 4 that extends outwards and has a flange structure, and its inner wall is provided with a second extension 5 that extends inwards and forms a bayonet. The outer wall of the first anchor section 2 on one side is provided with a third extension part 6 extending outward and having a flange structure;

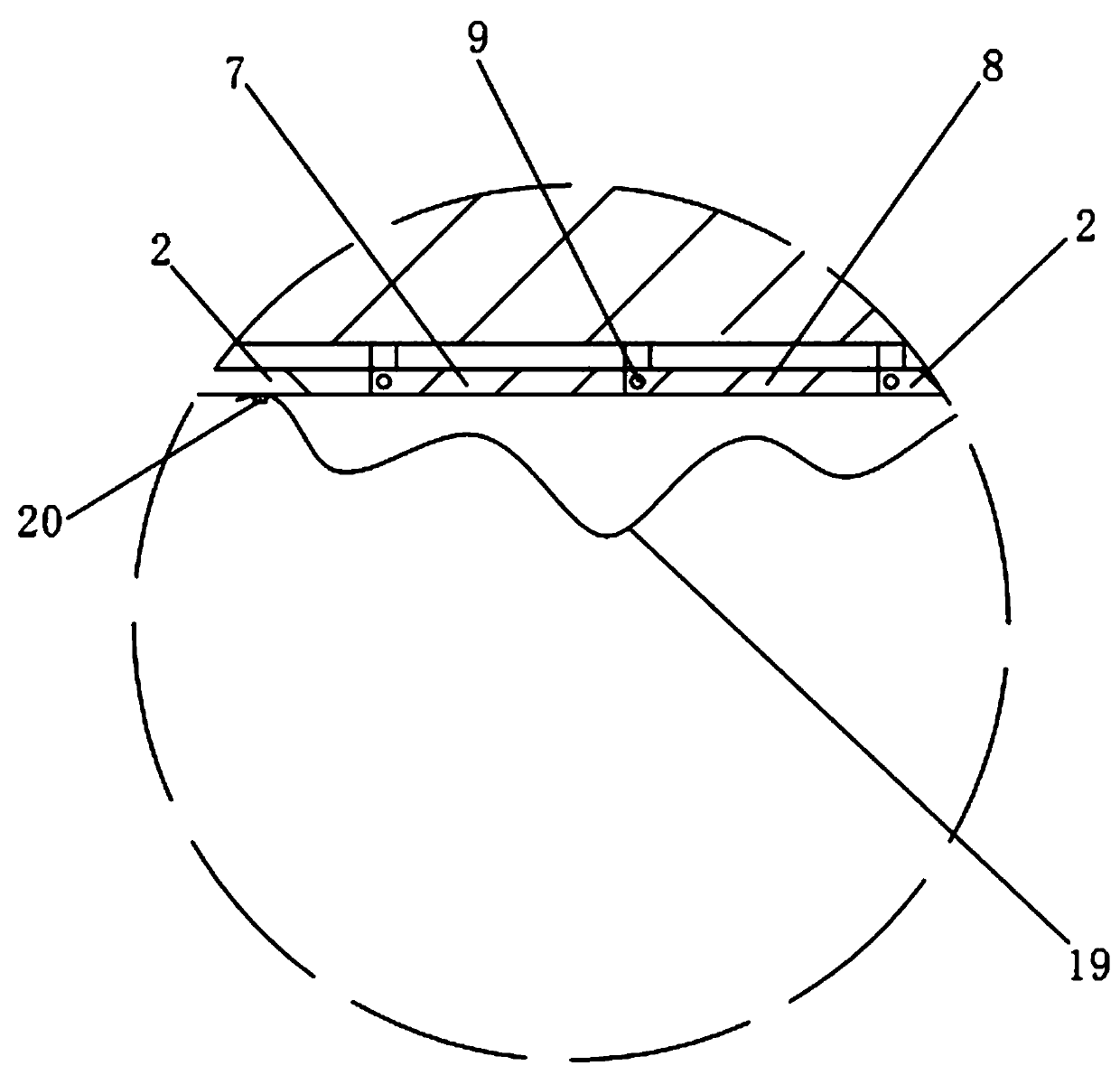

[0058] and, as image 3 and Figure 6 As shown, the hinged piece group located between every two adjacent first anchor rod segments 2, each hinged piece set inclu...

Embodiment 2

[0072] The general structure of the recoverable bolt provided in this embodiment is consistent with that of Embodiment 1, but, as Figure 10-13 As shown, in this embodiment, a raised portion 23 is provided on the inner wall of the second hinged piece 8 of each hinged piece group, and the raised portion 23 extends into the corresponding groove 24 on the center anchor rod 10, The protrusion 23 is provided with an opening rim 25 matching the groove 24 , and the protrusion 23 is driven away from the inclined guide surface 26 of the groove 24 under the thrust of the opening rim 25 .

[0073] When the hollow anchor 1 of the above-mentioned recoverable anchor begins to compress, synchronously, the opening edge 25 of each groove 24 on the central anchor 10 will apply a pushing force at the first time. The protrusion 23 of the second hinged piece 8 corresponding thereto makes it easier for the first hinged piece 7 and the second hinged piece 8 in each hinged piece group to overcome the...

Embodiment 3

[0075] The general structure of the recoverable bolt provided in this embodiment is consistent with that of Embodiment 2, but, as Figure 14 As shown, the central anchor rod 10 in this embodiment adopts a multi-stage detachable structure, which includes a plurality of second anchor rod segments 27 whose head and tail are fixed by threaded connection; the second anchor rod segments 27 are arranged in a straight line, and the axes coincide.

[0076] The above-mentioned central anchor 10 has a multi-stage detachable structure, and the second anchor section 27 extending from the reaming section 3 of the hollow anchor 1 can be easily disassembled to reduce the space occupied by the above-mentioned recoverable anchor during use. area.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com