A door buffer for a car door

A buffer and door technology, applied in door/window accessories, switches with braking devices, buildings, etc., can solve problems such as poor door closing sound quality, abnormal noise, vibration of door and window frames, etc., and achieve high impact compressive stress , less components, reducing the effect of instantaneous vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

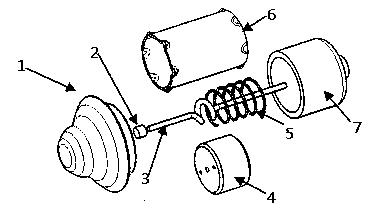

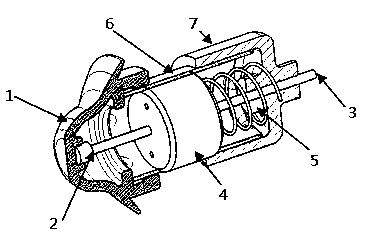

[0019] This program is implemented in this way, please refer to figure 1 , figure 2 and image 3 , this scheme is implemented in this way, the working principle is that there is a cavity inside the rubber buffer head 1, and a lip structure is reserved on the edge, the cavity reduces the vibration of closing the door, and the lip and the side wall fit to eliminate the gap and improve the appearance;

[0020] One end of the shaft sleeve 2 is inserted into the rubber buffer head 1, and one end is fixedly connected with the central shaft 3 through injection molding process, the purpose of which is to prevent the central shaft 3 from piercing the rubber buffer head 1 after repeated reciprocating work;

[0021] The middle shaft 3 adopts a spiral structure, and is fixedly connected with the pump plug 4 through injection molding process, and transmits the compression deformation from the rubber buffer head 1;

[0022] There are two exhaust holes on the pump plug 4, which make the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com