Refrigerator and defrosting control method thereof

A control method and refrigerator technology, applied in defrosting, household refrigeration equipment, lighting and heating equipment, etc., can solve the problems of insufficient defrosting, poor defrosting effect, energy waste, etc., and achieve improved heat utilization efficiency, chemical The effect of frost is better, and the effect of defrosting is direct

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

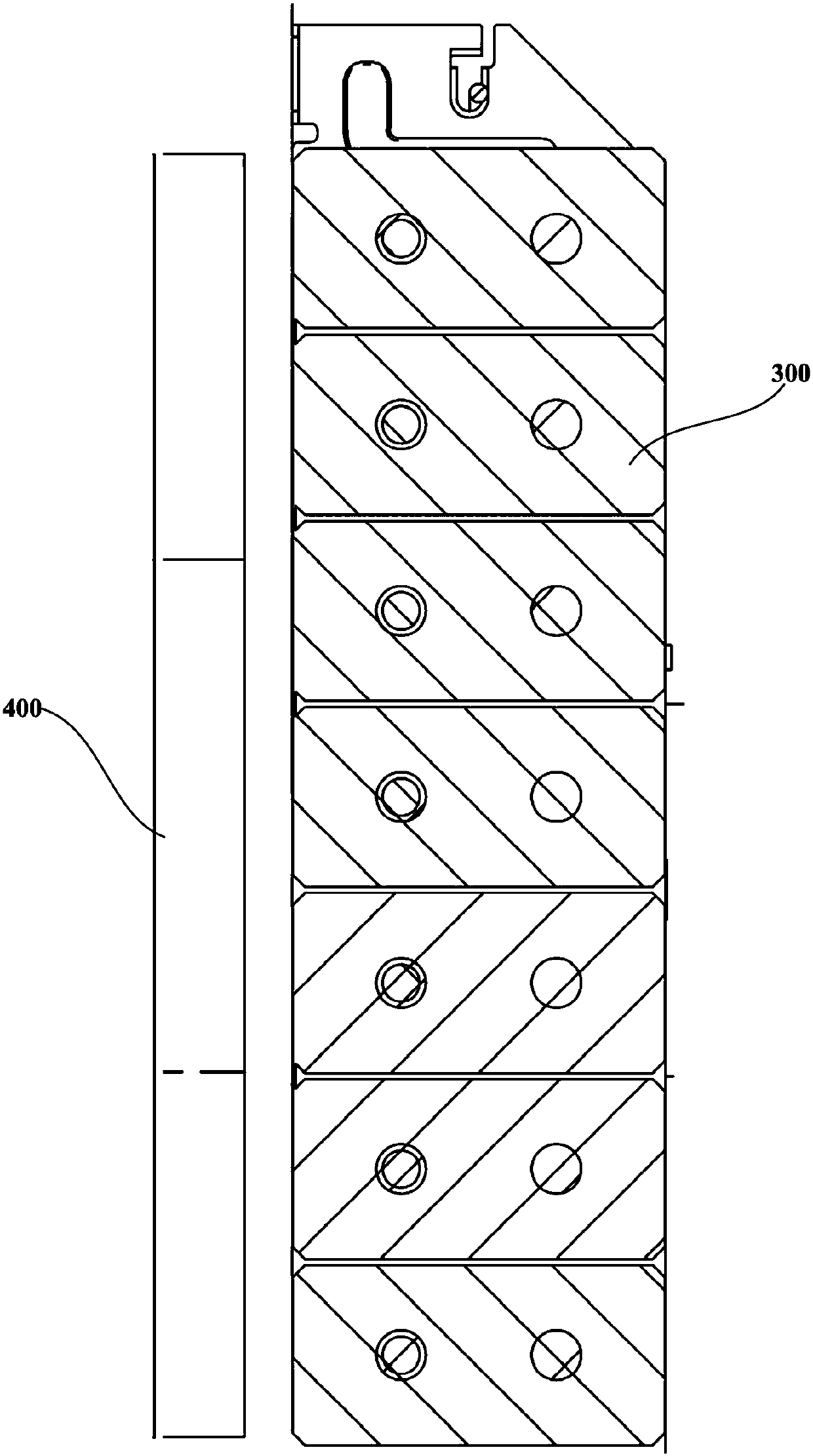

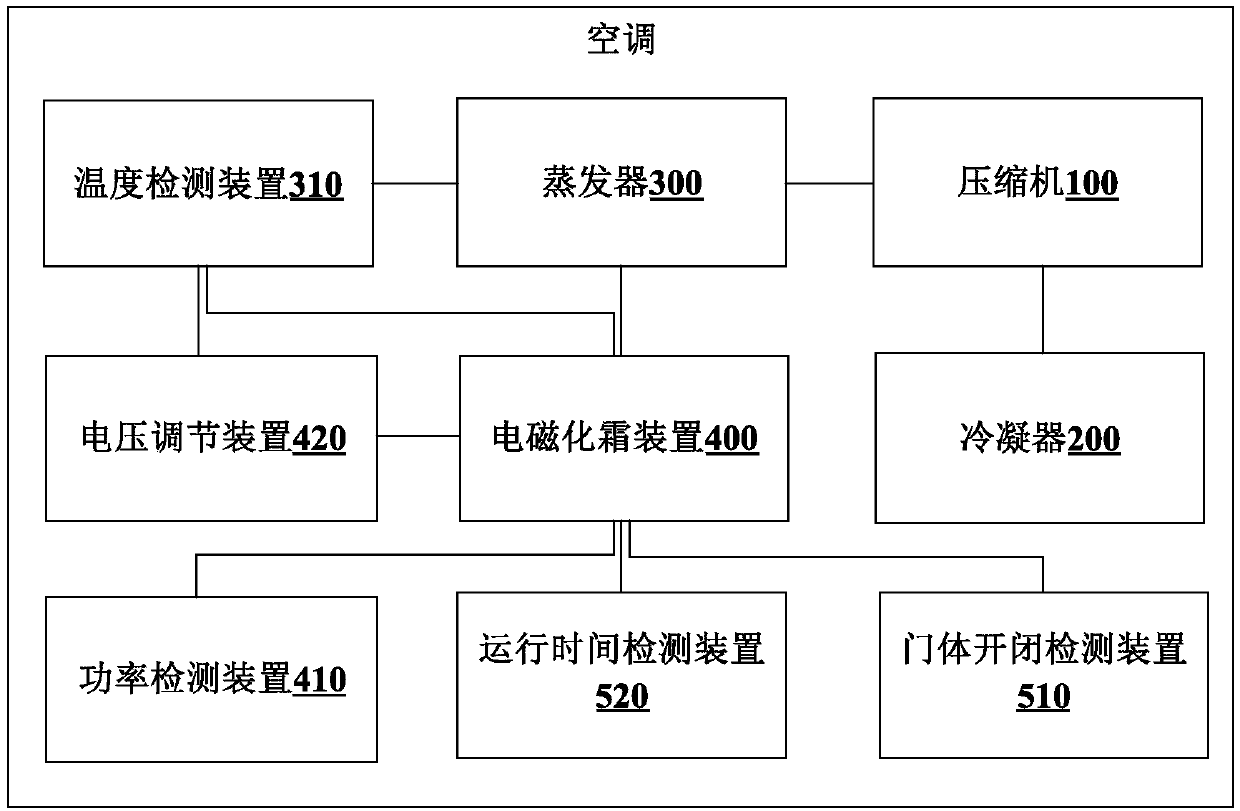

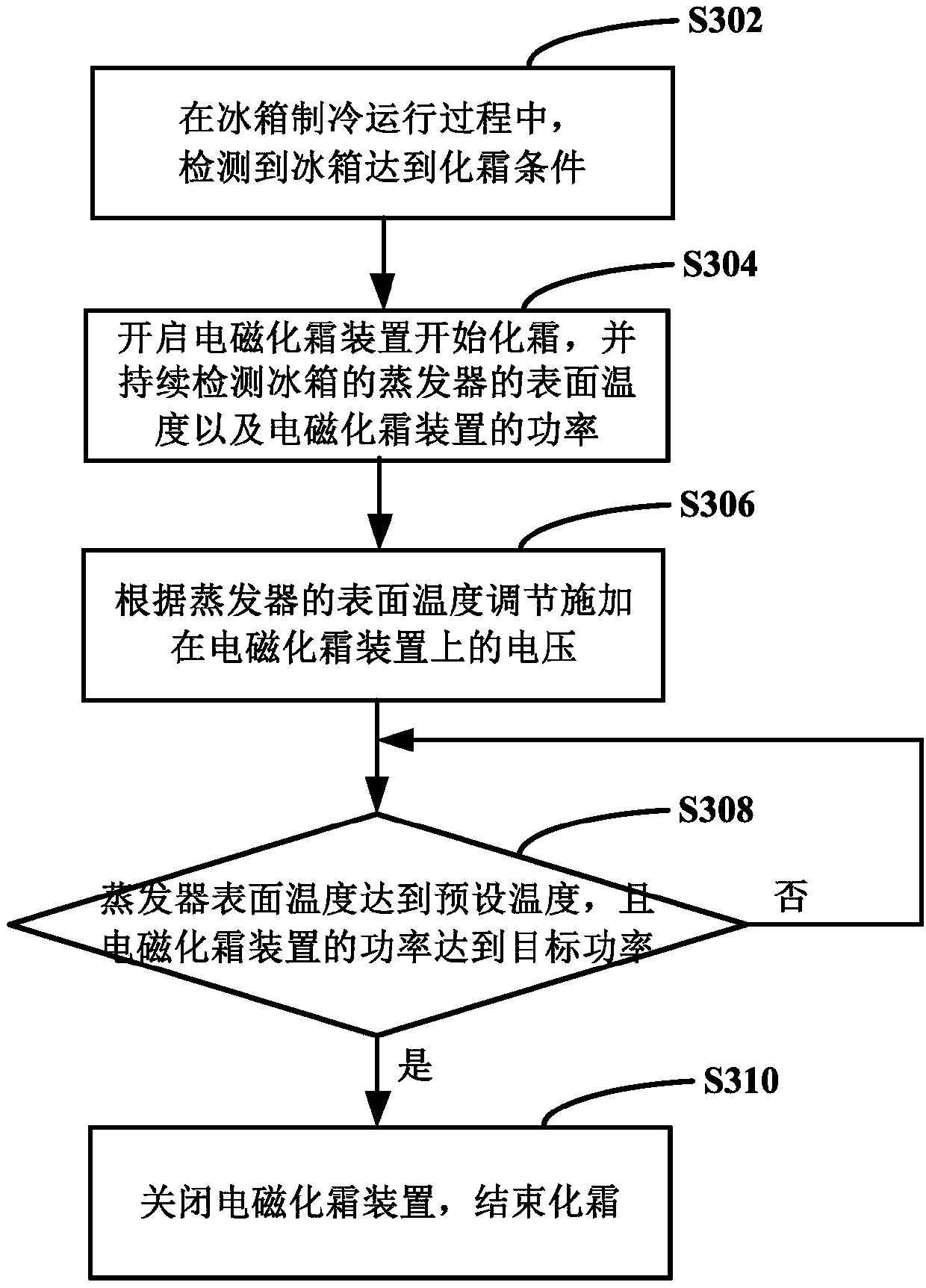

[0026] Such as figure 1 , figure 2 As shown, the embodiment of the present invention firstly provides a refrigerator. In this embodiment, the refrigerator is an air-cooled refrigerator, and the air-cooled refrigerator includes: a door body, a box body, and a refrigeration cycle system composed of a compressor 100 , an evaporator 300 and a condenser 200 . The inside of the box body forms a storage compartment and an air supply duct at the rear of the storage compartment. The evaporator 300 is arranged in the air supply duct. The pipe through which the refrigerant flows, and cools the air inside the air duct through the refrigerant flowing inside. A fan is also arranged inside the air supply duct, and the fan is used to transport the dry and cold air cooled by the evaporator 300 in the air duct to the storage room, so as to cool the storage room. Air entering the storage compartment is circulated again into the air duct. The interior of the air-cooled refrigerator uses the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com