Locking handle mechanism

A technology for locking handles and handle heads, which is applied in the field of locking handles of large-caliber weapons, can solve problems such as easy falling off, and achieve the effects of reliable fixing, simple structure and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

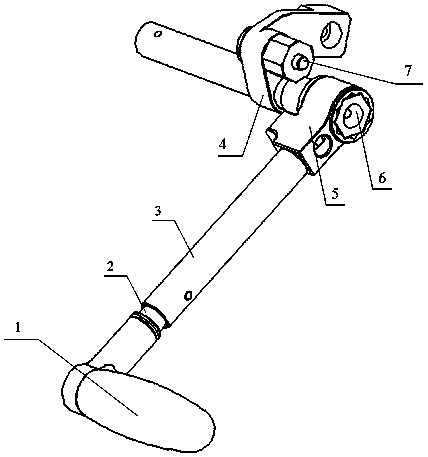

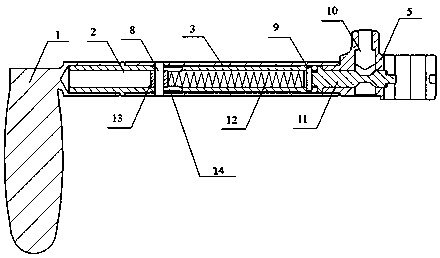

[0014] See figure 1 , figure 2 , the locking handle mechanism of the present invention includes a handle 1, a pull rod 2, a handle sleeve 3, a positioning seat 4, a handle head 5, a locking screw 6, a positioning top 7, a top block pin 8, a fixed rod pin 9, a positioning top Rod 10, fixed rod 11, return spring 12, reset top block 13.

[0015] The handle 1 is connected to the pull rod 2 by welding, the handle sleeve 3 is connected to the handle head 5 by welding, the positioning ejector rod 10 is loaded into the handle head 5, and the ejector block 13, the ejector block 13, Back-moving spring 12 and fixed rod 11 are packed in pull rod 2 and handle sleeve 3.

[0016] Positioning plug 7 The positioning plug 7 is installed on the positioning seat 4, and is ejected outward under the action of the inner spring force of the positioning seat 4, and the positioning plug 7 is pus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com