Method of achieving infinitely variable speeds for bike and infinitely variable speeds structure

A technology of continuously variable speed and bicycles, which is applied to vehicle gearboxes, vehicle components, wheel transmissions, etc., can solve problems that cannot really meet actual needs, and achieve the effect of preventing sediment from entering and making the riding process safe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

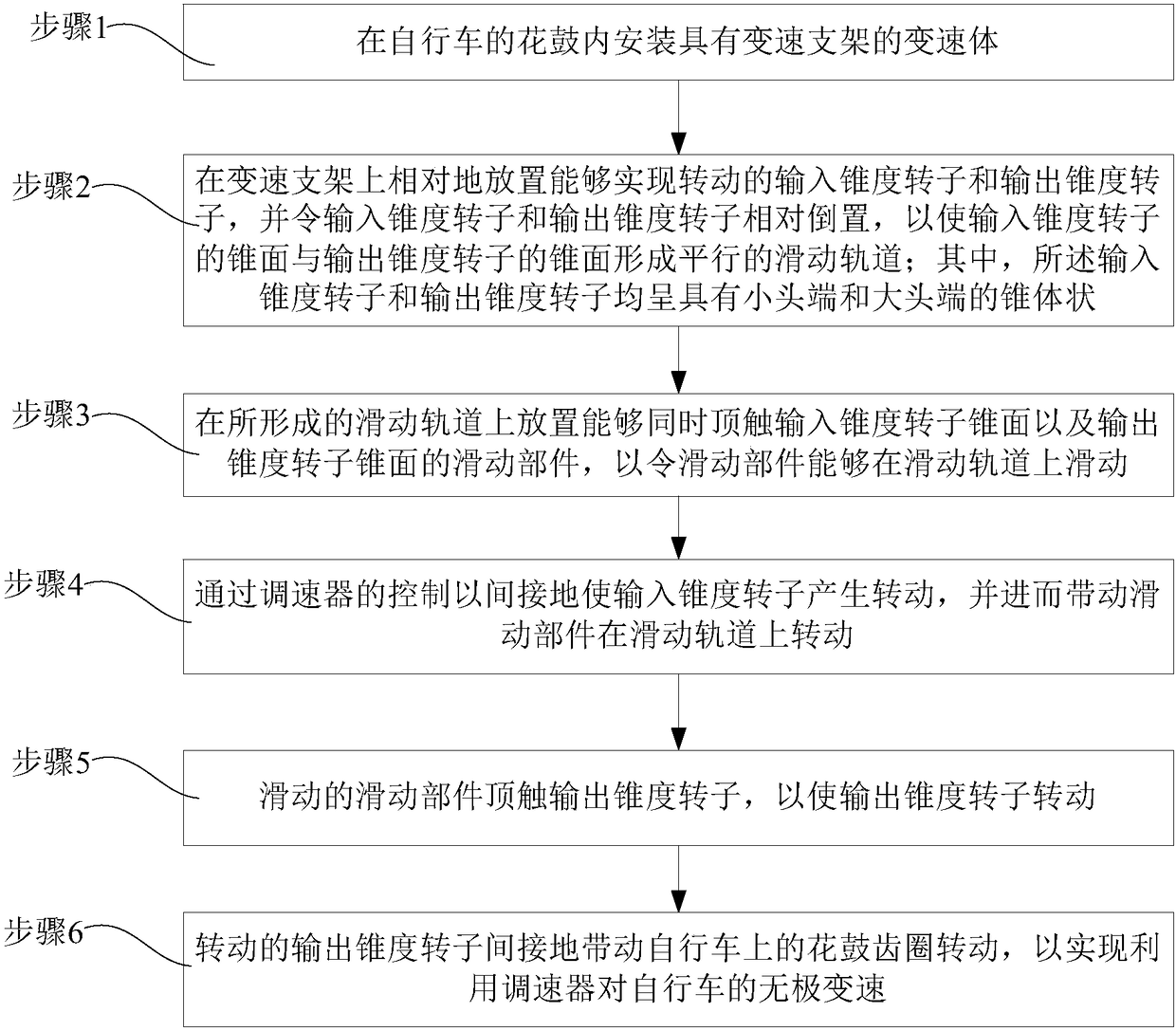

[0072] Such as figure 1 As shown, the method for realizing the stepless speed change of a bicycle in the first embodiment is used for a bicycle with a speed governor, and includes the following steps:

[0073] Step 1, installing a speed change body with a speed change bracket in the hub of the bicycle;

[0074] Step 2: Place the input tapered rotor and the output tapered rotor opposite to each other on the transmission bracket, and make the input tapered rotor and the output tapered rotor reversed so that the tapered surface of the input tapered rotor and the tapered output rotor form a Parallel sliding tracks; wherein, both the input tapered rotor and the output tapered rotor are in the shape of a cone with a small end and a large end;

[0075] Step 3, placing a sliding component capable of simultaneously touching the input tapered rotor cone surface and the output tapered rotor cone surface on the formed sliding track, so that the sliding component can slide on the sliding ...

Embodiment 2

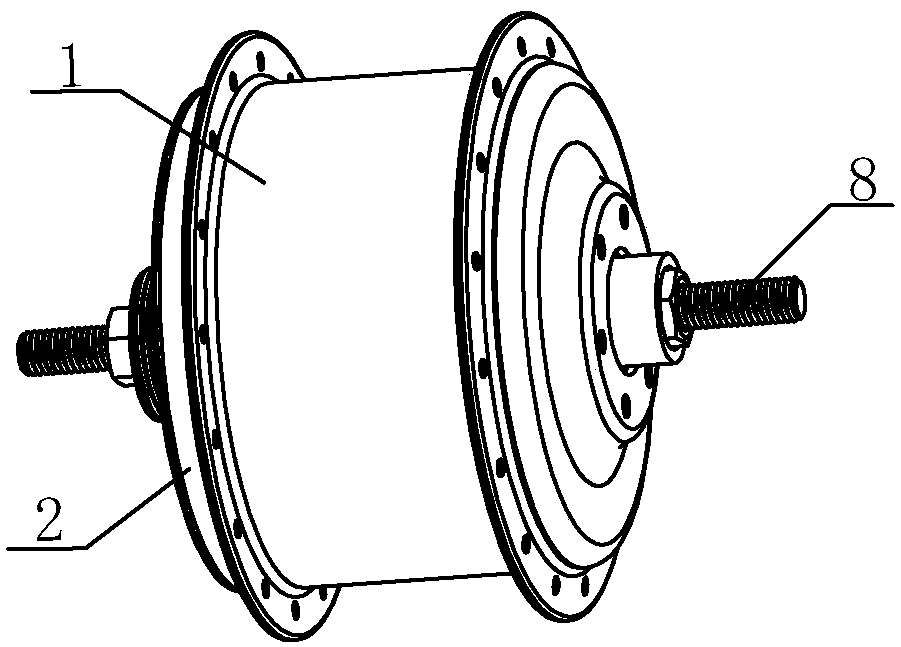

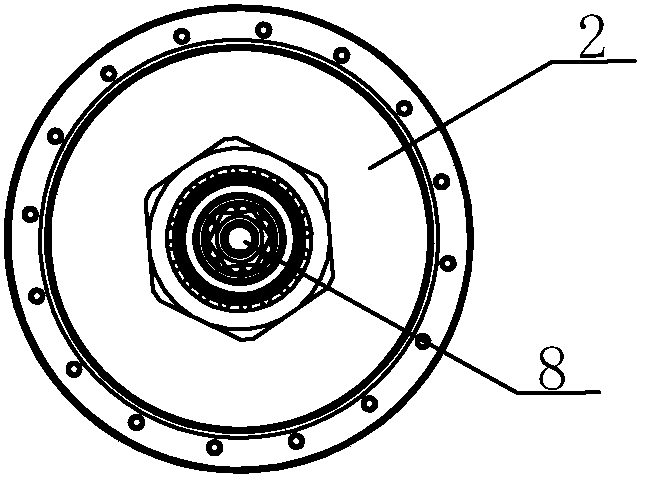

[0082] Such as Figure 2 to Figure 27 As shown, in the second embodiment, the continuously variable transmission structure for realizing the continuously variable transmission of the bicycle includes a hub 1 for connecting spokes, a hub cover 2, a hub ring gear 3, a transmission body 4, an input disc 5, and at least three An input tapered rotor 6, an output tapered rotor 7, and a main shaft 8; the hub 1 is tightly fitted with the hub cover 2; the tightly fitted hub 1 and the hub cover 2 form a sealed shell, thereby sealing and supporting the transmission body 4 function, which can also prevent the entry of mud and sand during riding, making the riding process safer and smoother, and prolonging the service life of the continuously variable transmission structure; among them:

[0083] The transmission body 4 has a first cavity 40 with both ends open, at least three first struts 41 and at least three second struts 42; each first strut 41 and each second strut 42 together play the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com