Anti-icing device for crankcase, crankcase ventilating system, engine and automobile

A crankcase ventilation and anti-icing technology, applied in crankcase ventilation, engine components, machines/engines, etc., can solve problems such as oil leakage, engine failure, and exhaust gas that cannot be removed in time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

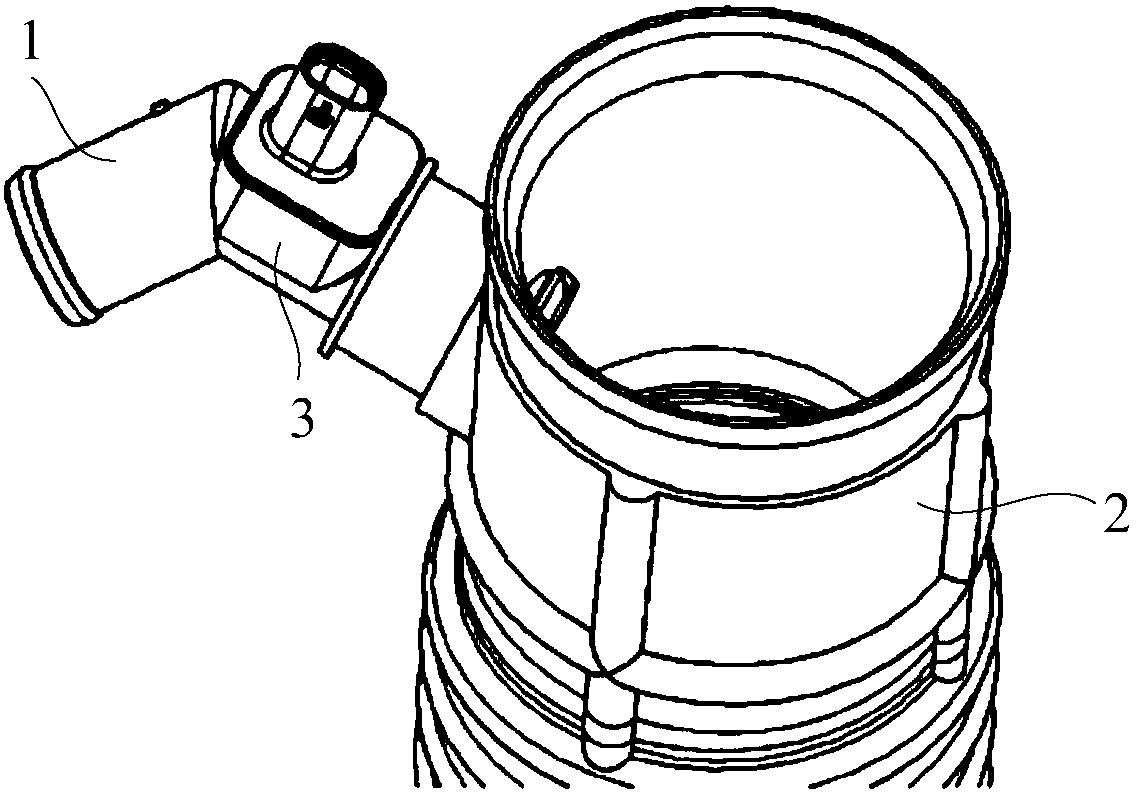

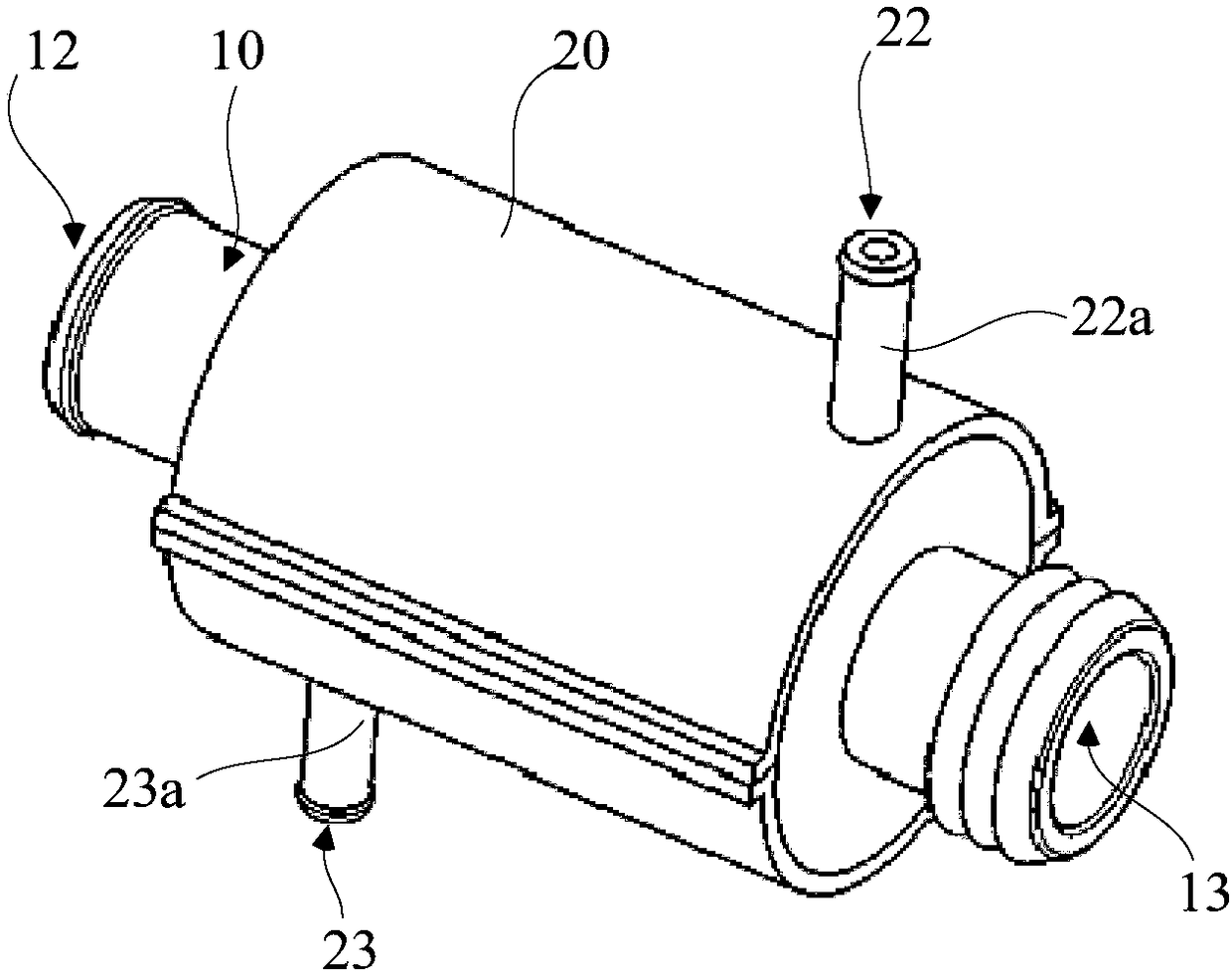

[0045] The embodiment of the present invention provides an anti-icing device for a crankcase, reference image 3 with Figure 4 , The anti-icing device includes: a first channel 11 for gas circulation. In this embodiment, the first channel 11 is for the circulation of crankcase exhaust gas; the shape of the first channel 11 is not limited, and can be cylindrical, rectangular or Cube-shaped. In this embodiment, the first channel 11 is cylindrical. Along the length direction of the first channel 11, both ends of the first channel 11 in the length direction have a first connection port 12 and a second connection port 13, and the first connection port 12 is used for Connect with crankcase ventilation pipe 40 (reference Image 6 ), the second connection port 13 is used to communicate with the air intake system.

[0046] In this embodiment, the first connection port 12 and the second connection port 13 are located at both ends of the length direction of the first passage 11. In other e...

Embodiment 2

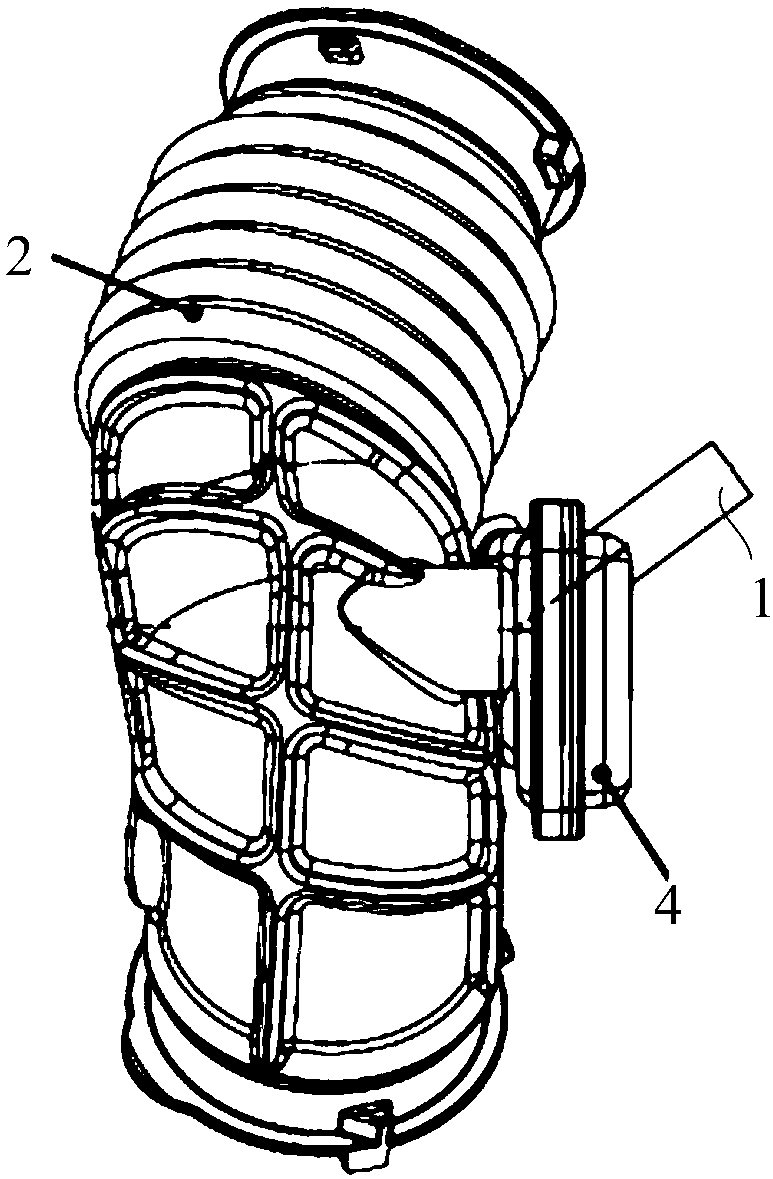

[0062] reference Image 6 And combine Figure 5 As shown, this embodiment provides a crankcase ventilation system, including: the anti-icing device for the crankcase in the first embodiment; a crankcase ventilation pipe 40 connected to the first connecting port 12, Image 6 It can be seen that the boss 30 on the outer peripheral surface of the first connecting port 12 is in interference fit with the inner wall of the crankcase ventilation pipe 40. The material of the crankcase ventilation pipe 40 is plastic or rubber, and the boss 30 will squeeze the crankcase ventilation pipe 40. The inner wall makes the boss 30 and the inner wall of the crankcase ventilation pipe 40 tightly connected together, and the sealing performance is good.

[0063] It also includes an air intake pipe 50, which is connected to the second connection port 13. In this embodiment, an air filter is provided on the air intake pipe 50, and a third connection port is provided between the air filter and the air inta...

Embodiment 3

[0069] The thermal fluid source in this embodiment is different from the thermal fluid source in the second embodiment, and the rest are the same. In this embodiment, reference Figure 7 And combine Figure 5 As shown, the hot fluid source further includes: a supercharger 80 arranged on the intake pipe 50; an intercooler 90 is also arranged on the intake pipe 50, and the supercharger 80 is closer to the intake pipe 50 than the intercooler 90 Air inlet; there is a hot fluid source outlet and a hot fluid source inlet between the supercharger 80 and the intercooler 90. The hot fluid source outlet is closer to the supercharger 80 than the hot fluid source inlet; the hot fluid inlet 22 passes through the pipe 81 is connected with the hot fluid source outlet, the boss 30 on the outer peripheral surface of the hot fluid inlet 22 is in interference fit with the pipe 81 to improve the sealing performance; the hot fluid outlet 23 is connected with the hot fluid source inlet through the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com