V-shaped upward-opening-type line-hanging traveling mechanism of inspection robot

A line inspection robot and walking mechanism technology, applied in motor vehicles, overhead lines/cable equipment, transportation and packaging, etc., can solve the problem of wire ropes stuck in non-moving parts, high consistency requirements, and affecting the power transmission of line inspection robots Line maintenance work and other issues, achieve the effect of low detection accuracy requirements, reduce development difficulty and cost, and easy to compile and design control algorithms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The content of the present invention will be further described below in conjunction with the drawings, but the actual manufacturing structure of the present invention is not limited to the embodiments shown in the drawings.

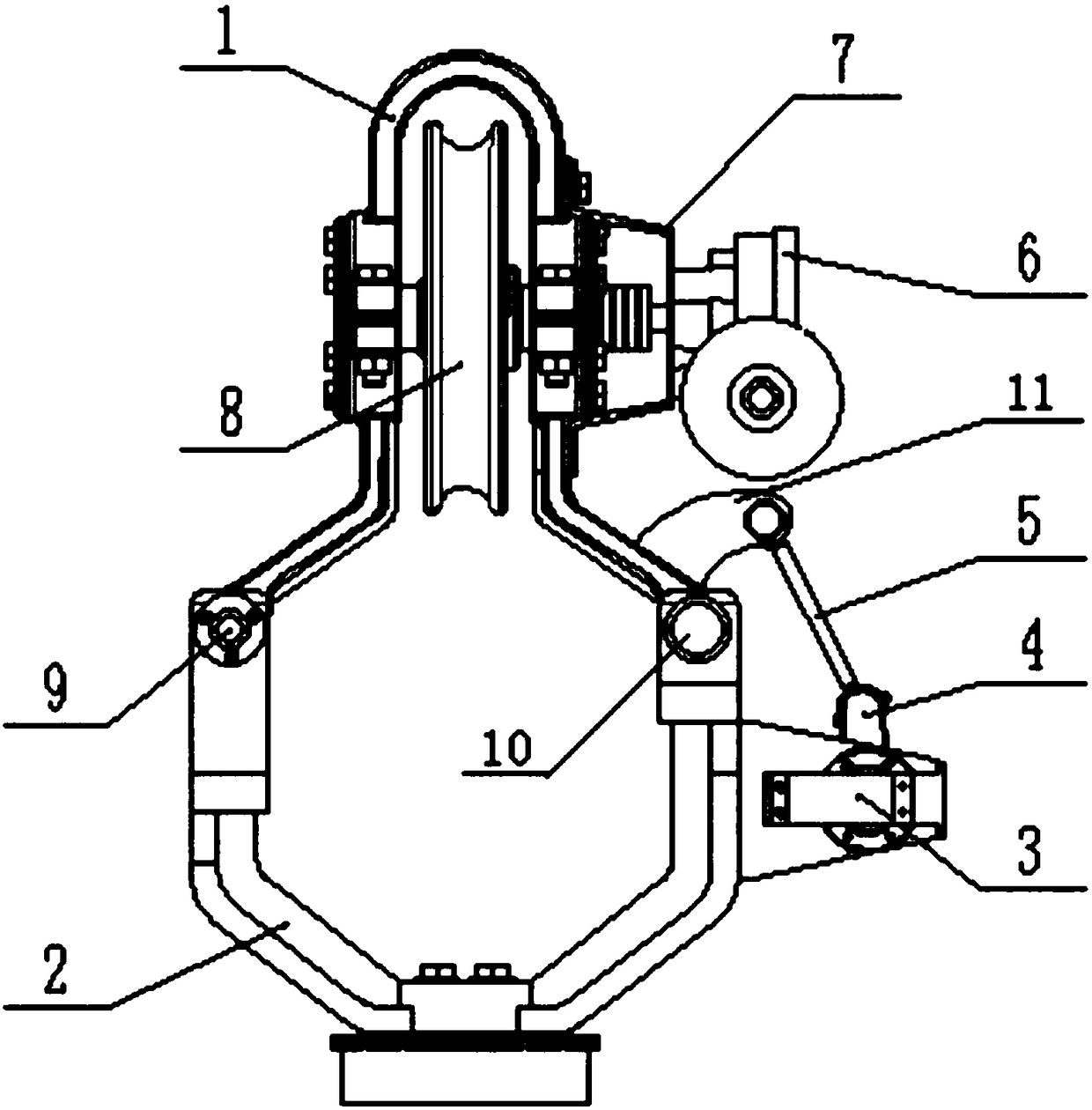

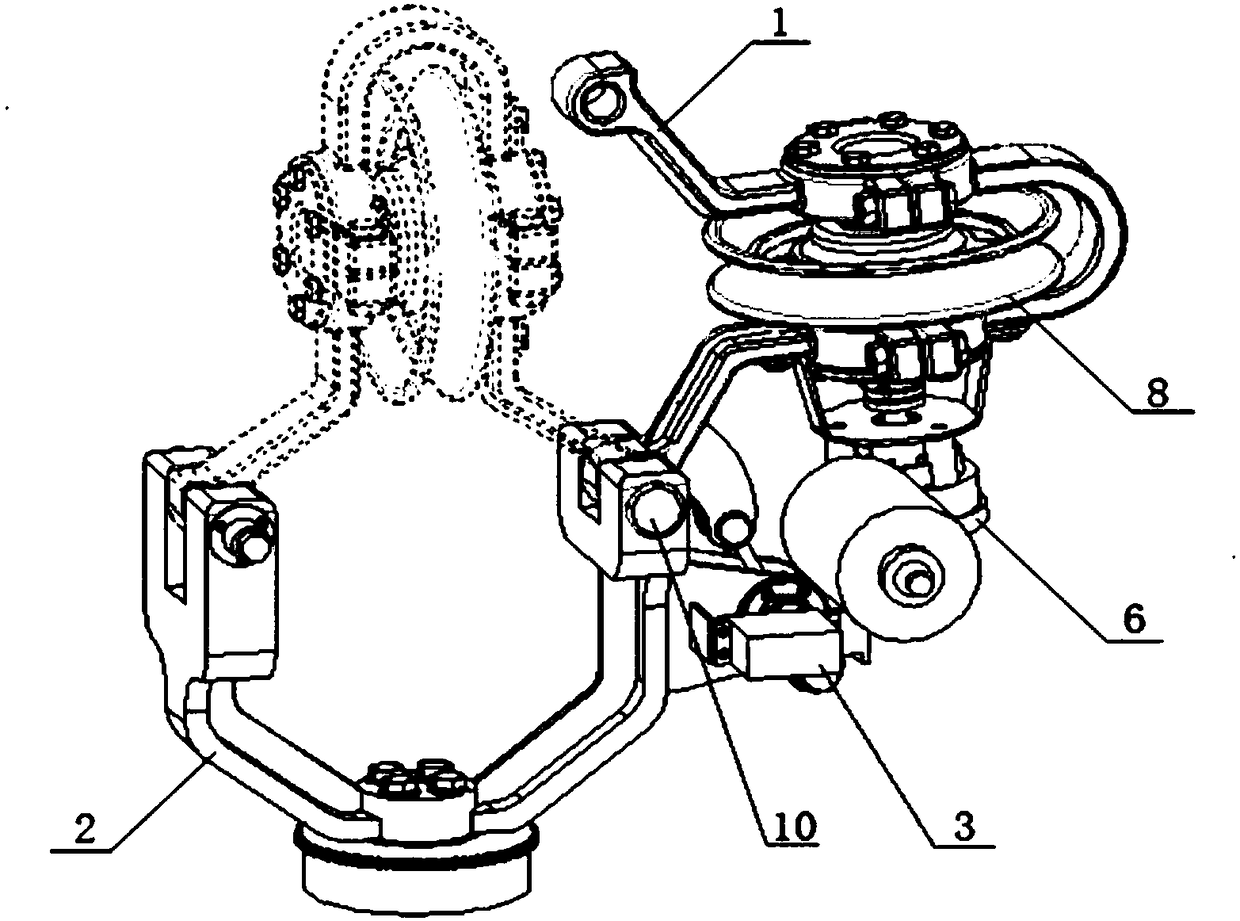

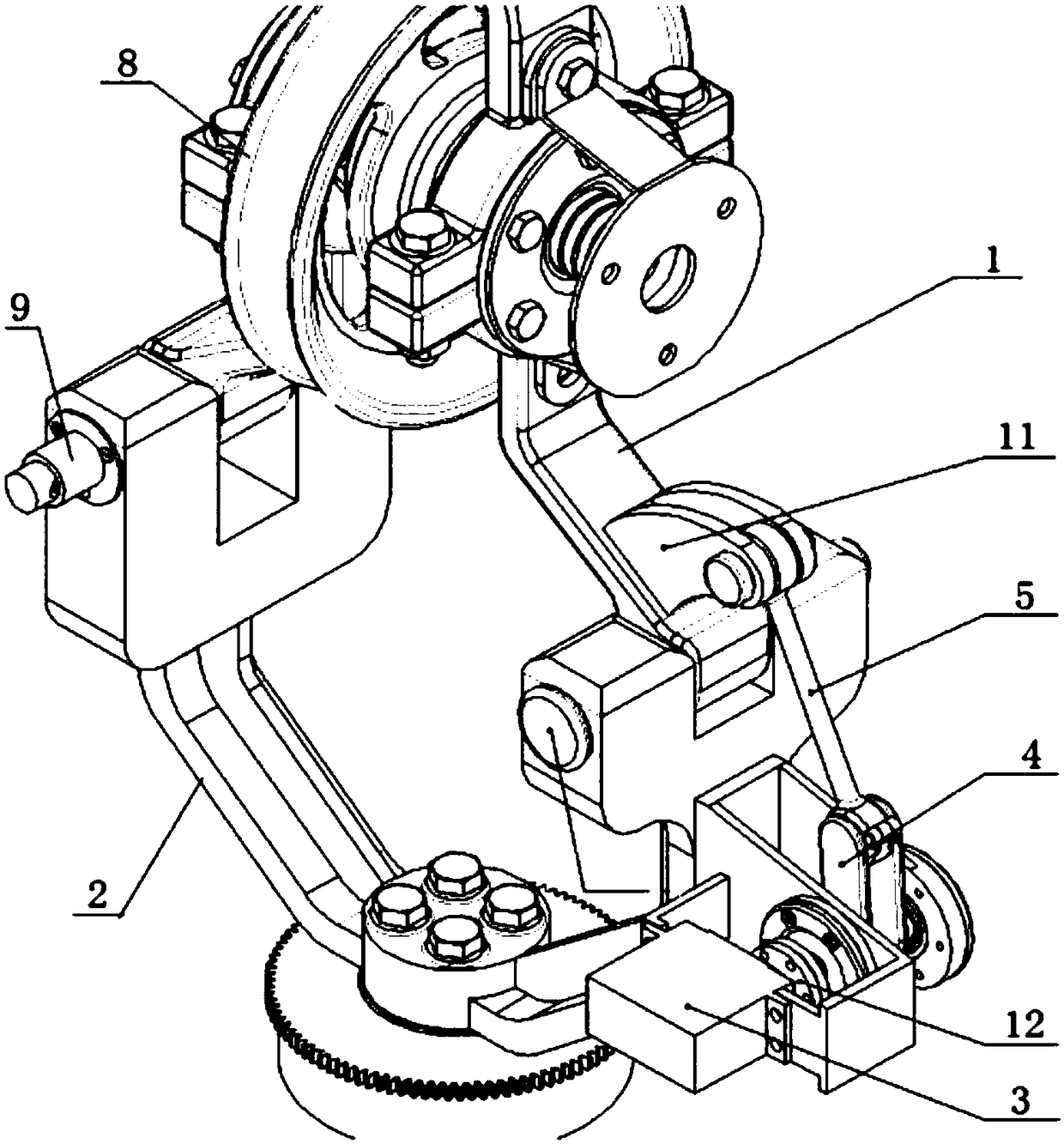

[0018] Referring to the accompanying drawings, the V-type top-opening hanging wire walking mechanism of the line patrol robot according to the present invention is mainly composed of an upper gripper 1 and a lower gripper 2 . The upper gripper 1 is composed of an inverted V-shaped bracket, and a bearing support is arranged symmetrically on both sides of the inverted V-shaped bracket. The shaft rod of the walking wheel 8 is mounted on the two bearing supports. The frame bar of the bracket is equipped with a motor support 7, and the driving motor 6 is installed on the motor support 7, and its output shaft is connected with the shaft rod of the walking wheel 8 through a coupling; the lower grip 2 adopts a U-shaped support design, and its The bottom is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com