Laser-air water coaxial jet coupling head and underwater laser machining device

A coaxial jet and processing device technology, applied in the direction of metal processing equipment, laser welding equipment, manufacturing tools, etc., can solve the problems of difficult to accurately control the focus accuracy and position, fast energy dissipation, and affect the processing quality, etc., to achieve focus control accuracy Reduced requirements, simple device structure, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

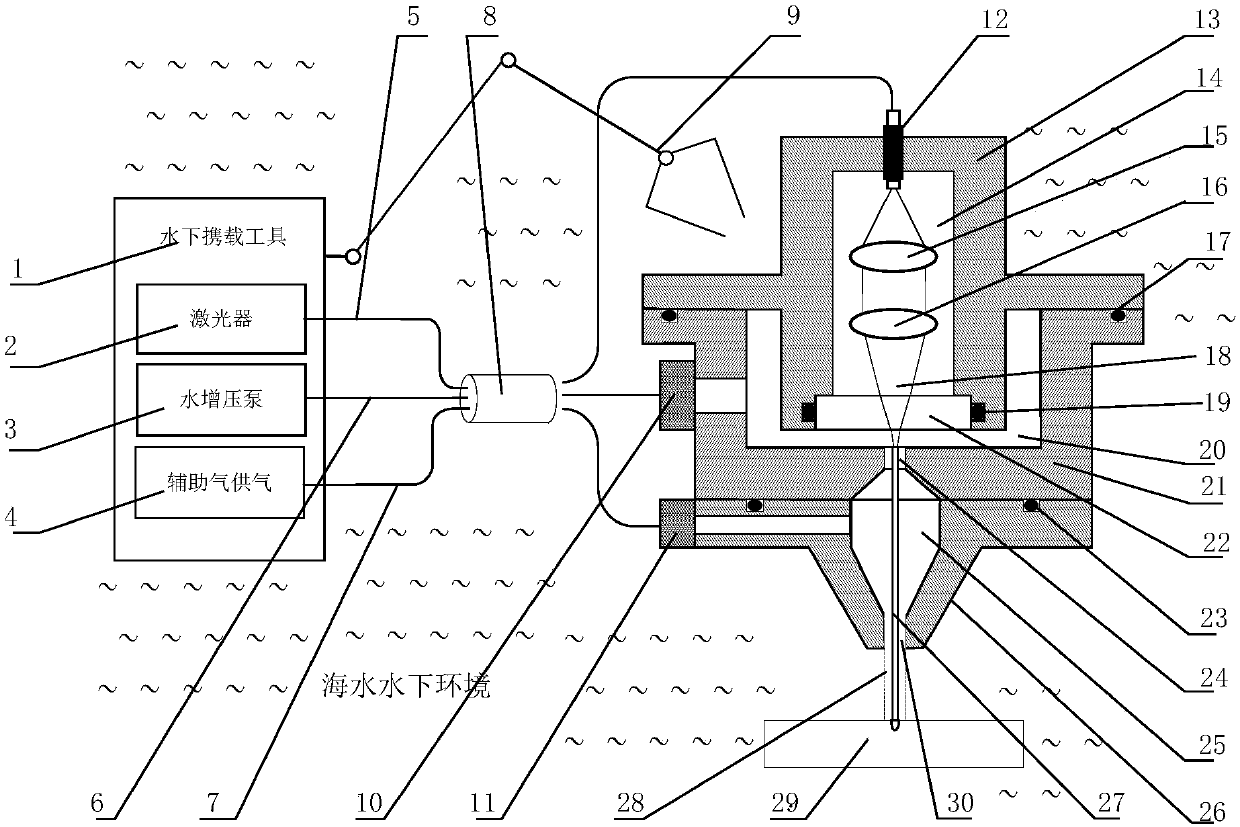

[0049] Such as figure 1 Shown is a kind of underwater air-water coaxial jet assisted laser processing device of the present invention, and its concrete composition is as follows:

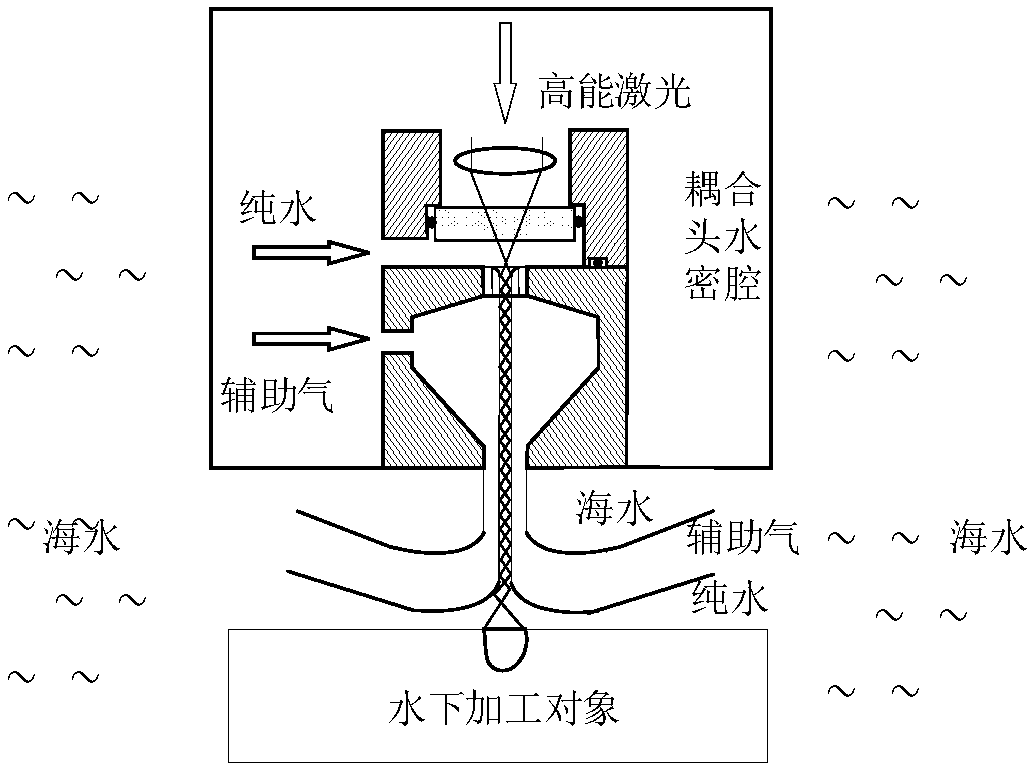

[0050] The device mainly includes a laser-air-water coaxial jet coupling head, a laser 2 and an optical path system, a water booster pump 3, and an auxiliary gas supply device 4. The whole set of devices can be carried to the underwater processing site by the underwater carrier 1 . The laser-air-water coaxial jet coupling head is composed of a laser optical path watertight cavity 14 with a working water depth and watertight design, a high-pressure water cavity 20 and an auxiliary air-scavenging cavity 25 . The coupling head moves and processes under the operation of the mechanical arm and the clamping mechanism 9 . The laser 2 and the optical path system provide laser irradiation required for processing. The water booster pump 3 provides the boosted pure water needed for jet flow. Auxiliary air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com