Aircraft fuel system

A fuel system and aircraft technology, applied in the direction of charging system, machine/engine, fuel tank safety measures, etc., can solve the problems of low safety, large space, troublesome installation and maintenance of the fuel system, etc., to achieve easy installation and maintenance, The effect of simple fuel system, improved safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

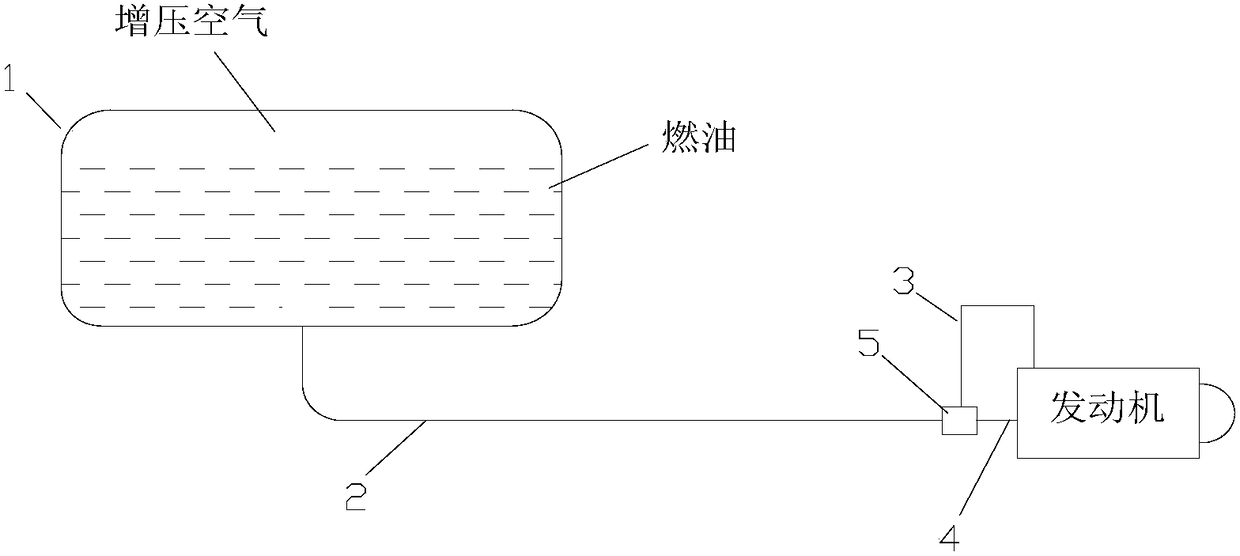

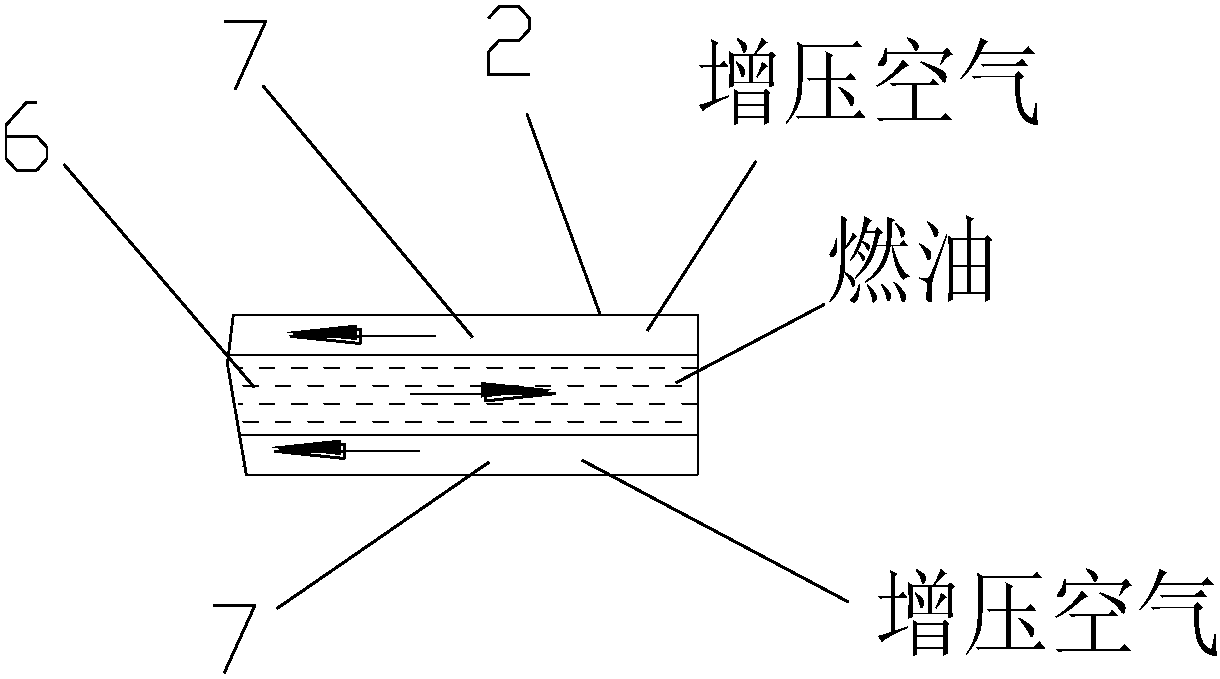

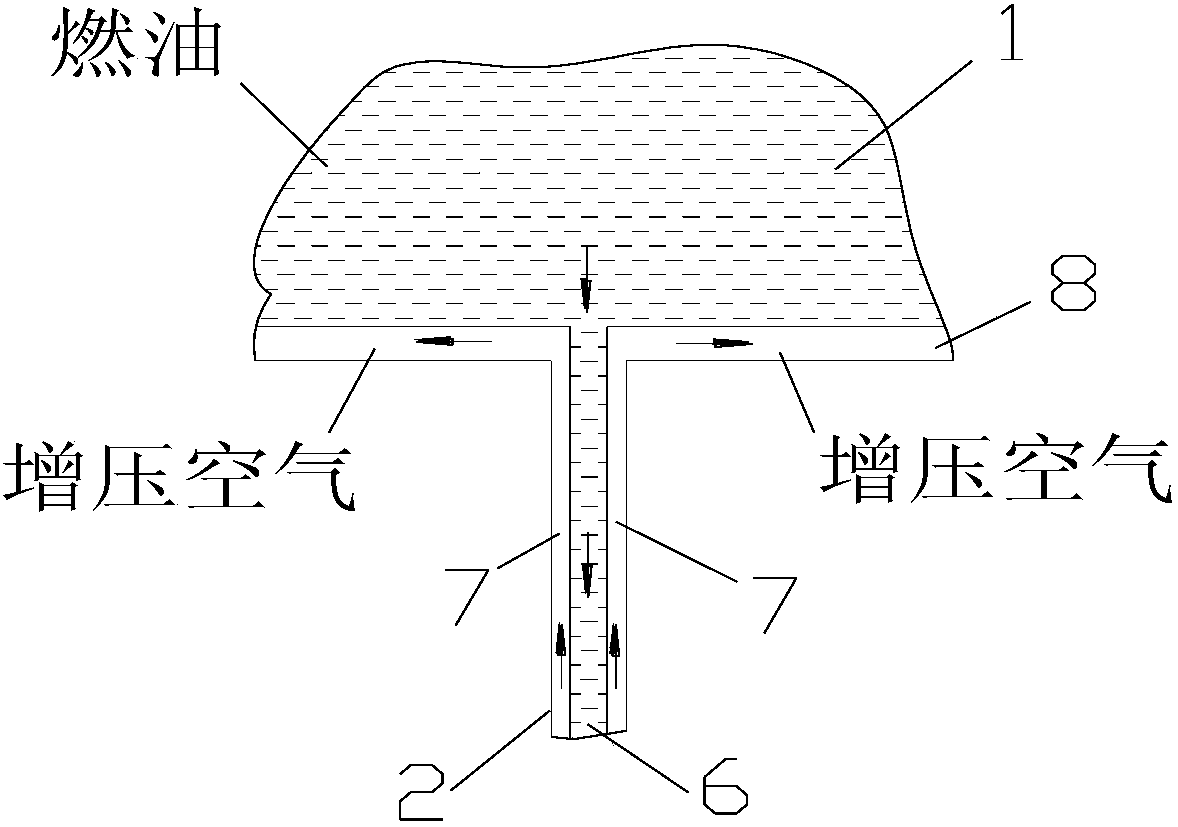

[0032] The fuel system consists of a fuel tank 1, a dual-channel pipeline 2, a bleed air connection pipe 3, a fuel supply connection pipe 4, and a channel separator 5.

[0033] Component function: fuel tank 1 realizes fuel loading; dual-channel pipeline 2 realizes the introduction of engine bleed air into fuel tank 1 and fuel tank 1 to the engine; fuel tank 1 is equipped with a sealed partition for pressurized gas passage The pressurized air enters the top of the fuel tank to pressurize the fuel in the fuel tank; the channel separator 5 realizes the separation of the oil and gas medium pipelines in the dual channel pipeline 2, and is connected to the engine through the bleed air connecting pipe 3 and the fuel supply connecting pipe 4 The air outlet is connected to the fuel inlet, and a pressure reducing valve is installed in the channel separator 5 to achieve engine bleed air pressure reduction and meet the fuel boost pressure requirement.

[0034] The working principle of the syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com