Pre-combustion stage direct injection main combustion stage pre-mixing pre-evaporation three-swirl combustion chamber

A technology of main combustion level and pre-combustion level, which is applied in the field of three-swirl combustion chamber, can solve the problems of complex structure and fuel supply system, high weight, etc., and achieve the effect of compact combustion chamber head, simple fuel system and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

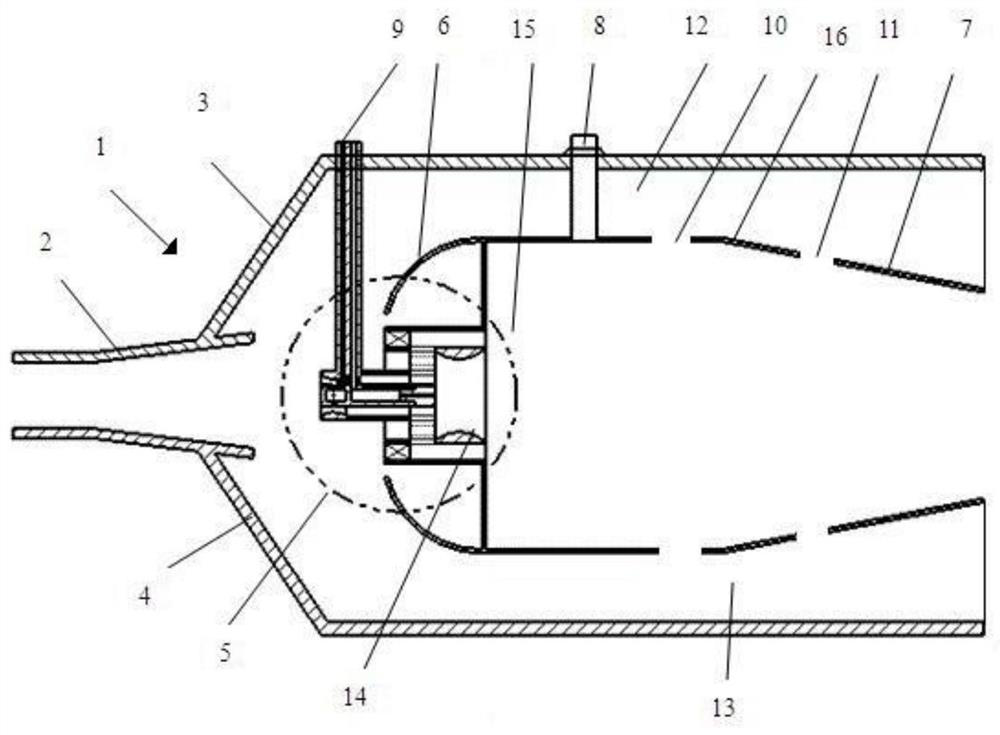

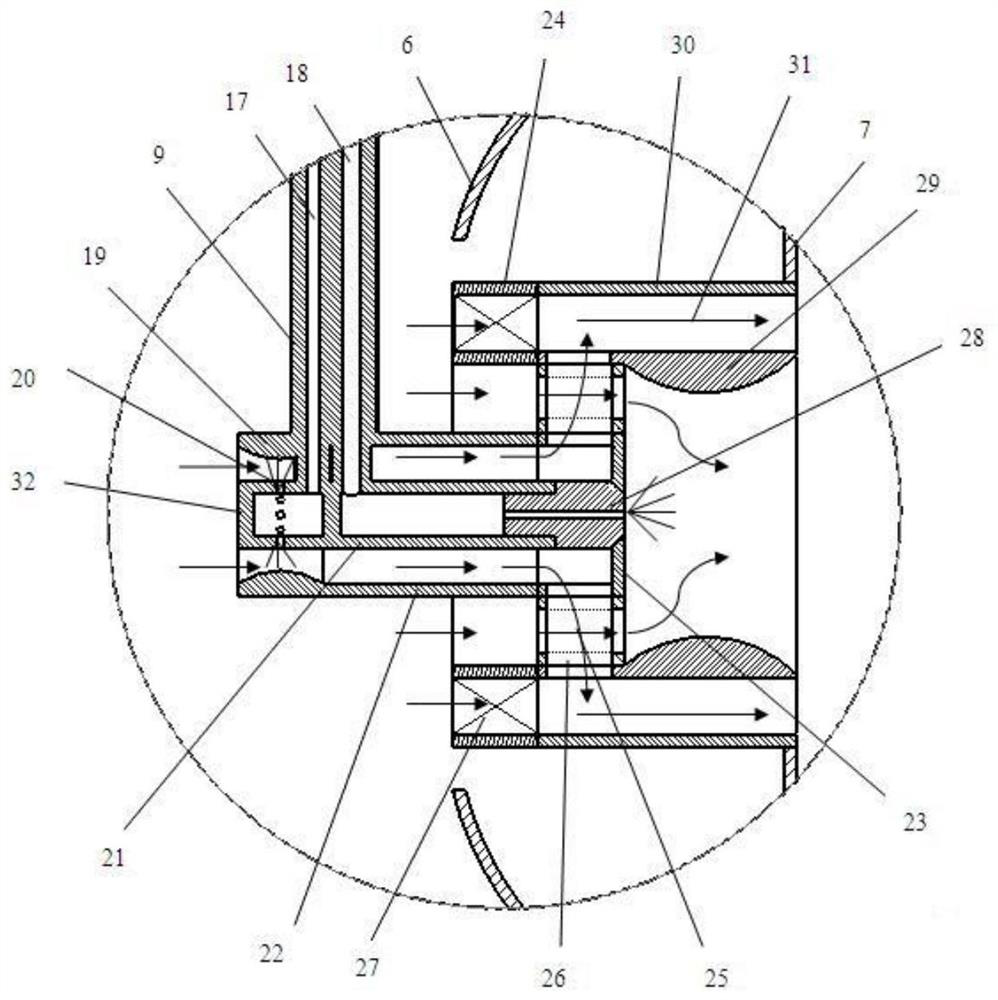

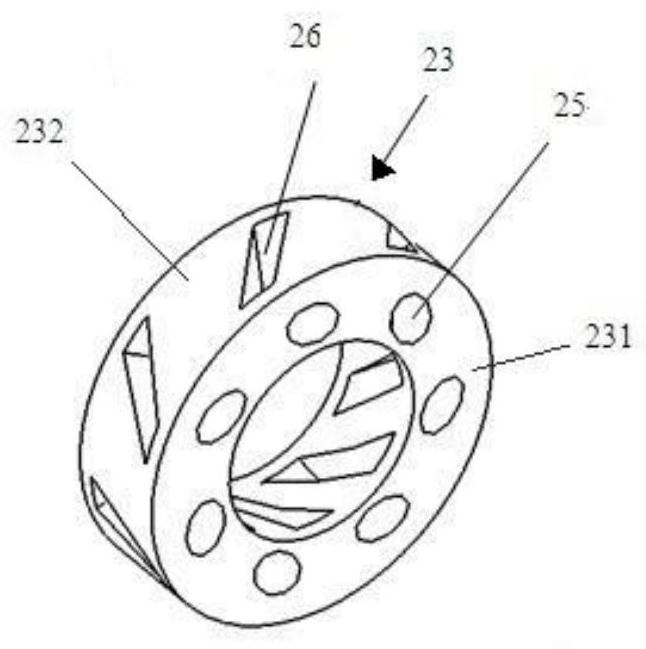

[0029] Such as figure 1 As shown, a three-swirl combustor 1 of a pre-combustion stage direct injection main combustion stage premixed pre-evaporation of the present invention includes a diffuser 2, an outer casing 3, an inner casing 4, a flame tube 7, and a high-energy ignition electric Nozzle 8, oil supply pipe 9 and flame tube head 5, flame tube 7 is provided with main combustion hole 10, mixing hole 11 and cooling hole 16, flame tube head 5 is composed of pre-combustion stage 14 and main combustion stage 15 , wherein the outer casing 3 and the inner casing 4 are the main load-bearing parts of the combustion chamber 1, and constitute the outer ring passage 12 and the inner ring passage 13 of the combustion chamber 1 with the flame tube 7, and the entrance of the combustion chamber 1 is provided with Diffuser 2, its main function is to reduce the air veloci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com