A semiconductor dry and wet contact fault diagnosis circuit and diagnosis method

A fault diagnosis and semiconductor technology, applied in electrical testing/monitoring, instrumentation, testing/monitoring control systems, etc., can solve the problem that there is no effective solution for fault diagnosis, effective diagnosis, and detection of wet contacts cannot be effectively used circuit and other problems, to achieve the effect of simple structure, simple judgment method and reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

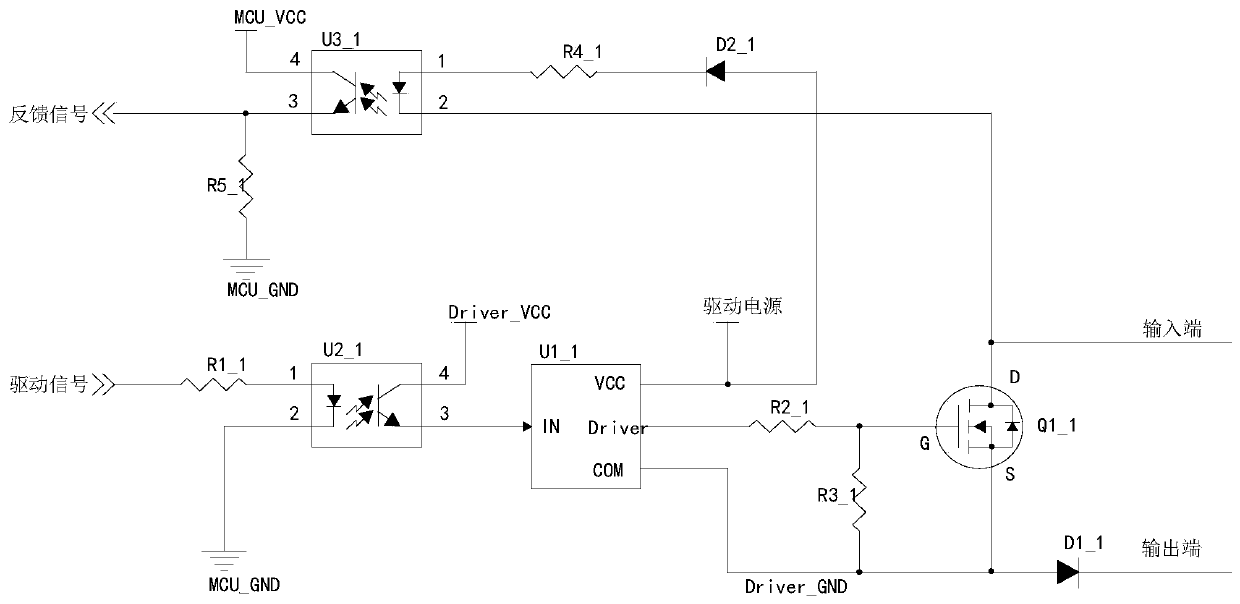

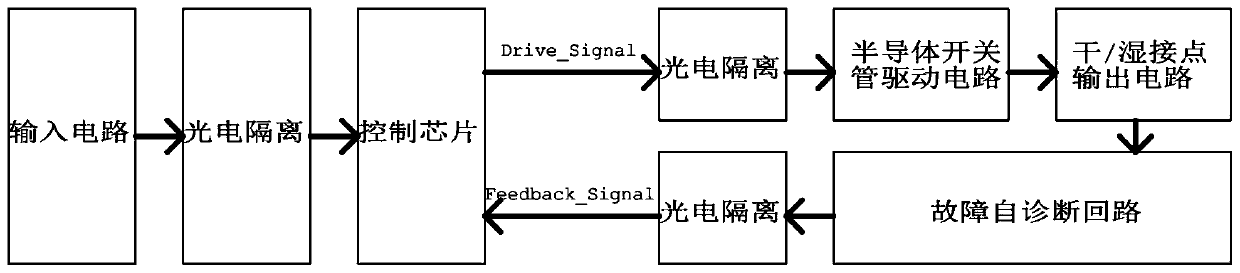

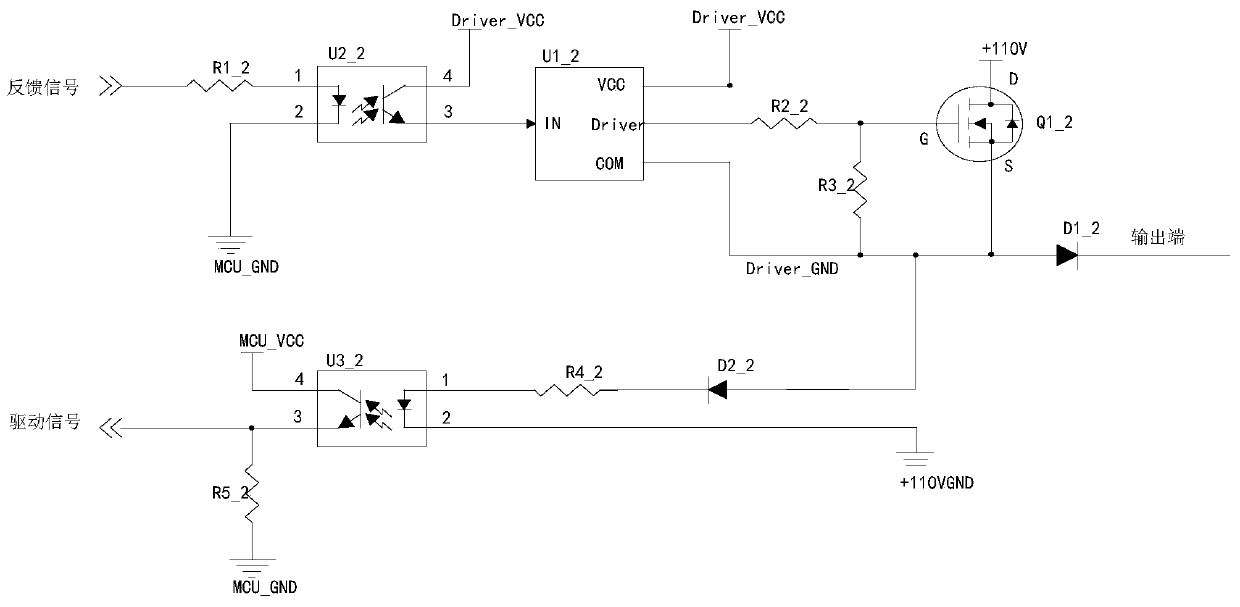

[0027] Such as figure 1 As shown, a semiconductor dry and wet contact fault diagnosis circuit includes a semiconductor switch U2_1, a dry and wet contact Q1_1, a semiconductor switch U3_1, the input end of the semiconductor switch U2_1 is used to receive a drive signal, and the semiconductor switch U2_1 The output terminal of the semiconductor switch U3_1 controls the conduction and closure of the dry and wet contact Q1_1, the input terminal of the semiconductor switch U3_1 is connected to the dry and wet contact Q1_1, and the output terminal of the semiconductor switch U3_1 outputs a feedback signal; when the dry and wet contact Q1_1 is turned on , the output terminal of the semiconductor switch U3_1 outputs a valid feedback signal, and when the dry-wet contact Q1_1 is turned off, the output terminal of the semiconductor switch U3_1 outputs an invalid feedback signal.

[0028] The semiconductor switch U2_1 adopts an optocoupler, and the dry and wet contact Q1_1 adopts one of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com