Special device for detecting VL-type universal joint inner star wheel raceway pitch diameter and detection method

A technology of pitch circle diameter and detection device, applied in the direction of mechanical diameter measurement, etc., can solve the problems that it cannot be applied to the production site environment for rapid measurement application, cannot directly measure the diameter value, and cannot directly measure the size, etc., to meet the requirements of mass production and detection. Fast, simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

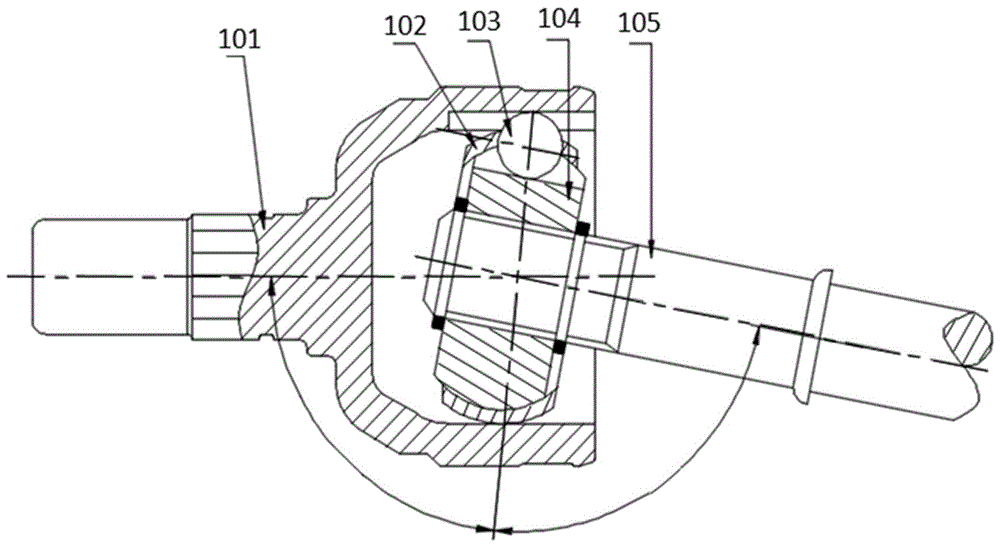

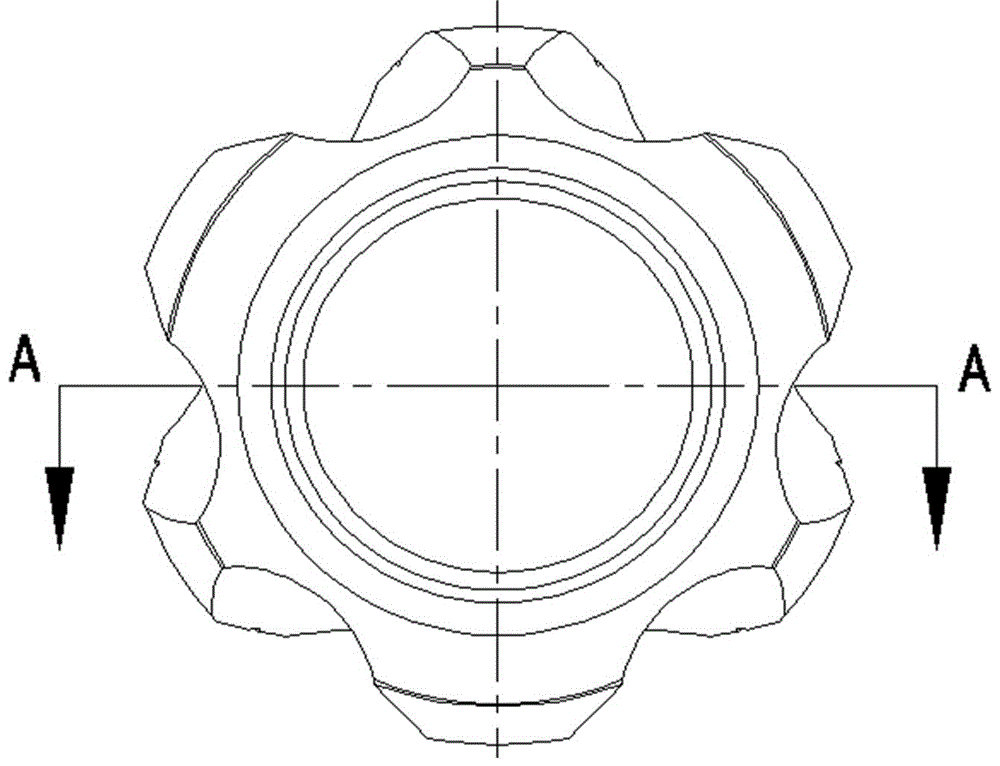

[0058] The specific implementation of the special detection device and detection method for the pitch circle diameter of the inner star wheel raceway of the VL type universal joint of the present invention will be described in detail below in conjunction with the accompanying drawings.

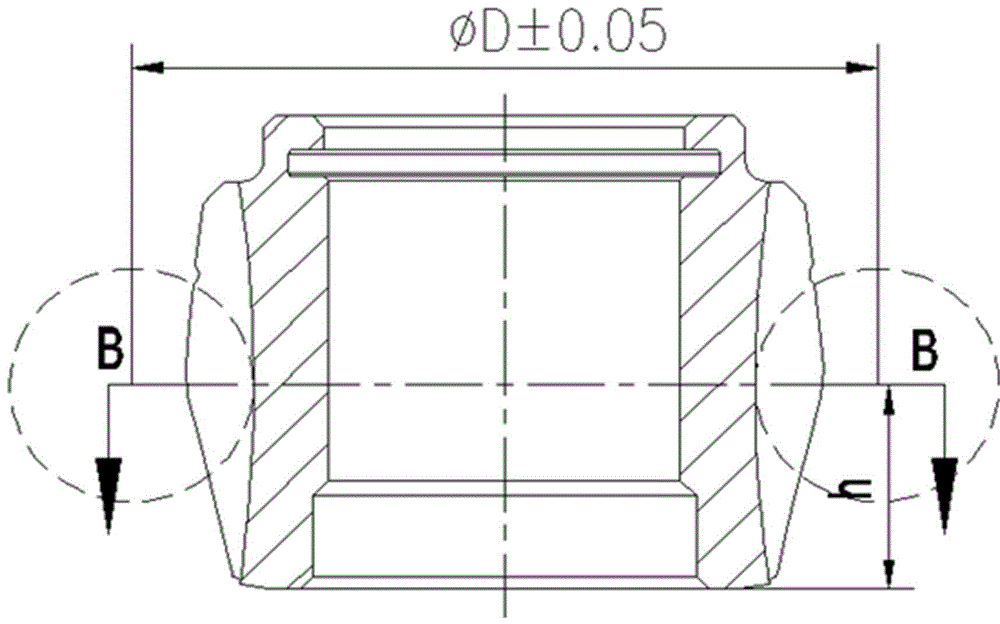

[0059] See attached Figures 2 to 8 , because the six raceways of the inner star wheel are uniformly distributed only on the system plane BB, the diameter error value of the circle (that is, the pitch circle) formed by the centers of the six raceways on the system plane BB is ±0.05mm, Figure 8 Among them, points O1 and E1 represent the center of the raceway and the most concave point (that is, the tangent point) when the deviation is positive 0.05 mm, and points O2 and E2 represent the center of the raceway and the most concave point (that is, the tangent point) when the deviation is negative 0.05 mm. ), the distance OO between the two centers of the left and right raceways in the direction o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com