AOI (Automatic Optic Inspection) multi-station system and method based on PPC (Pocket Personal Computer) software

A multi-station, software technology, applied in general control systems, control/regulation systems, comprehensive factory control, etc., can solve problems such as complex hardware redundancy, improve integration, reduce complexity and cost, and reduce man-machine. The effect of the interactive interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

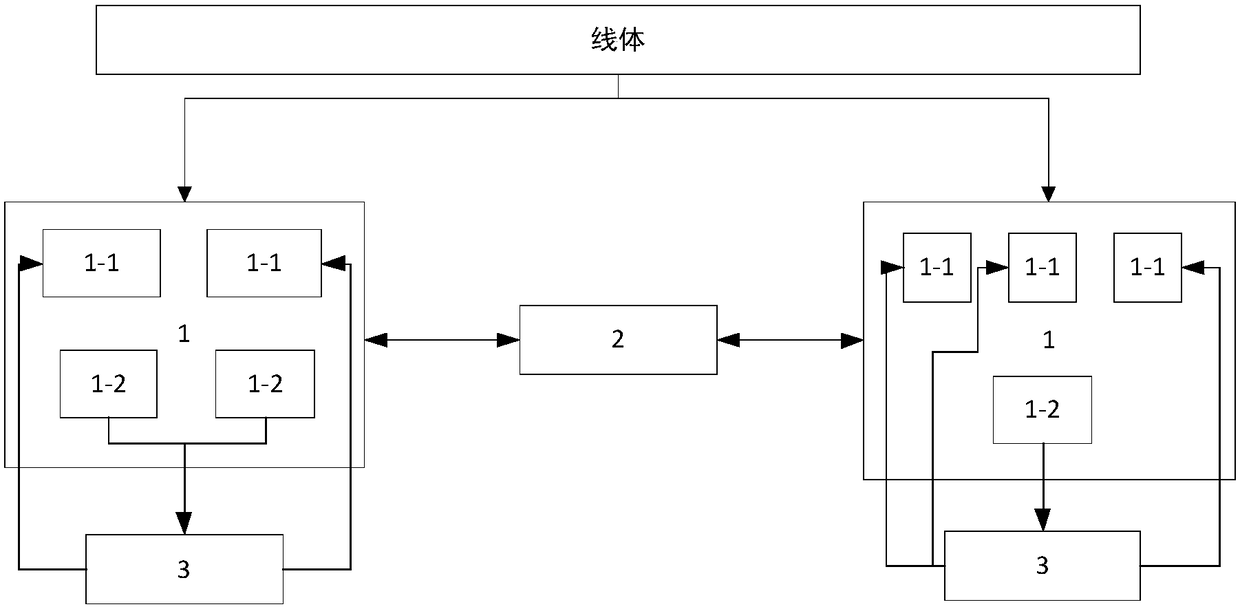

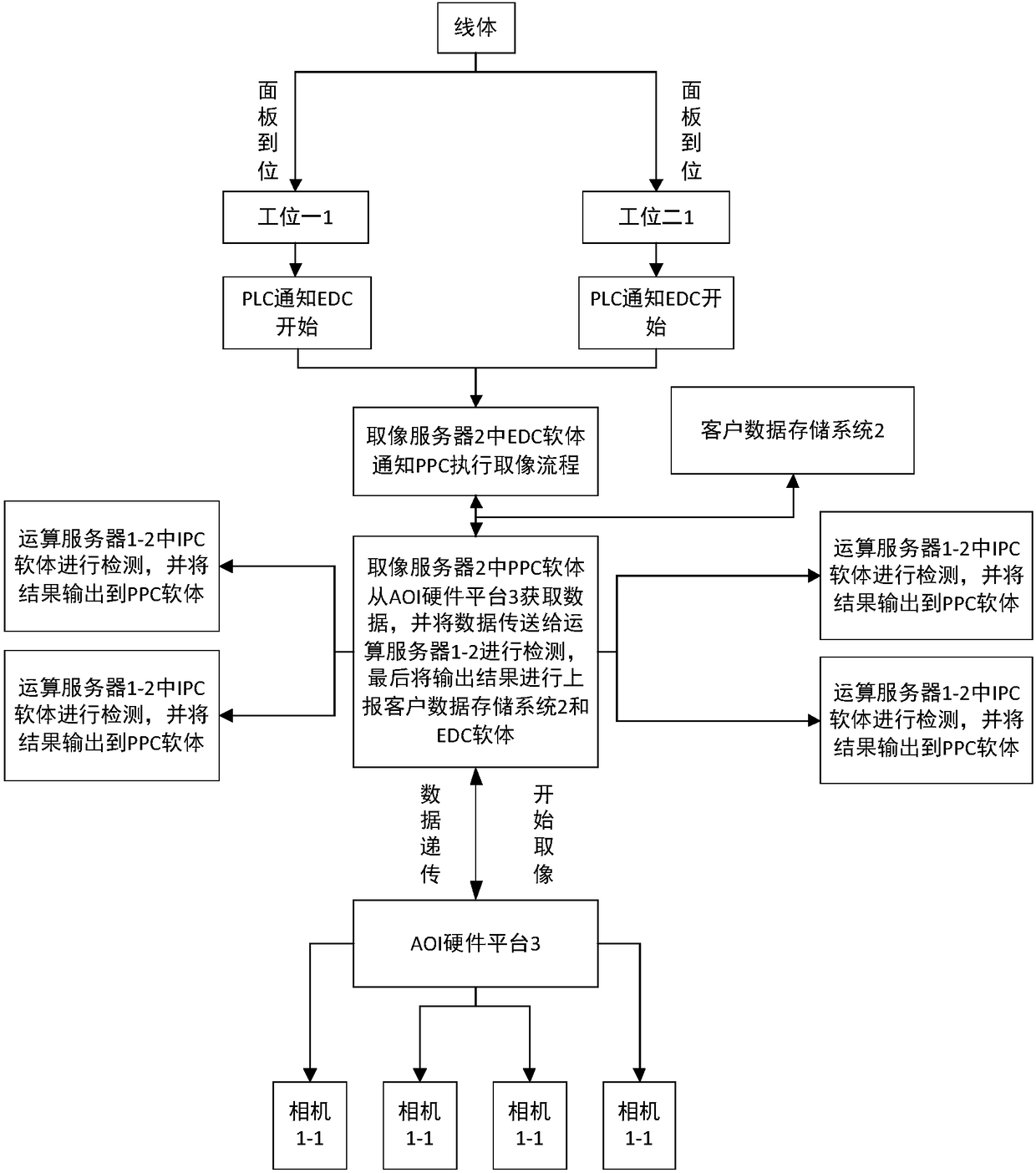

[0027] Such as figure 1 As shown, the PPC software-based AOI (Automatic Optic Inspection, automatic optical inspection system) multi-station system provided by the present invention includes a plurality of stations 1 , an imaging server 2 and an AOI hardware platform 3 . Each station 1 includes a number of computing servers 1-1 and a number of cameras 1-2, which are used to power on the panel to be inspected, take pictures of the panel, and inspect the image data. The computing server 1-1 is used to deploy IPC software (InspectpersonalComputer, inspection system computer) to inspect image data. Image acquisition server 2 is used to deploy EDC (External Device Control, external device control) software and PPC software (Processpersonal Computer, image acquisition server computer), record the feature information of station 1, issue pow...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap