Piston type high-pressure tensile hydraulic nut

A technology of high-pressure tensioning and hydraulic nuts, which is applied in the direction of nuts, threaded fasteners, connecting components, etc., can solve the problems of difficult disassembly of bolts, and achieve the effects of meeting pre-tightening requirements, avoiding use, and facilitating disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

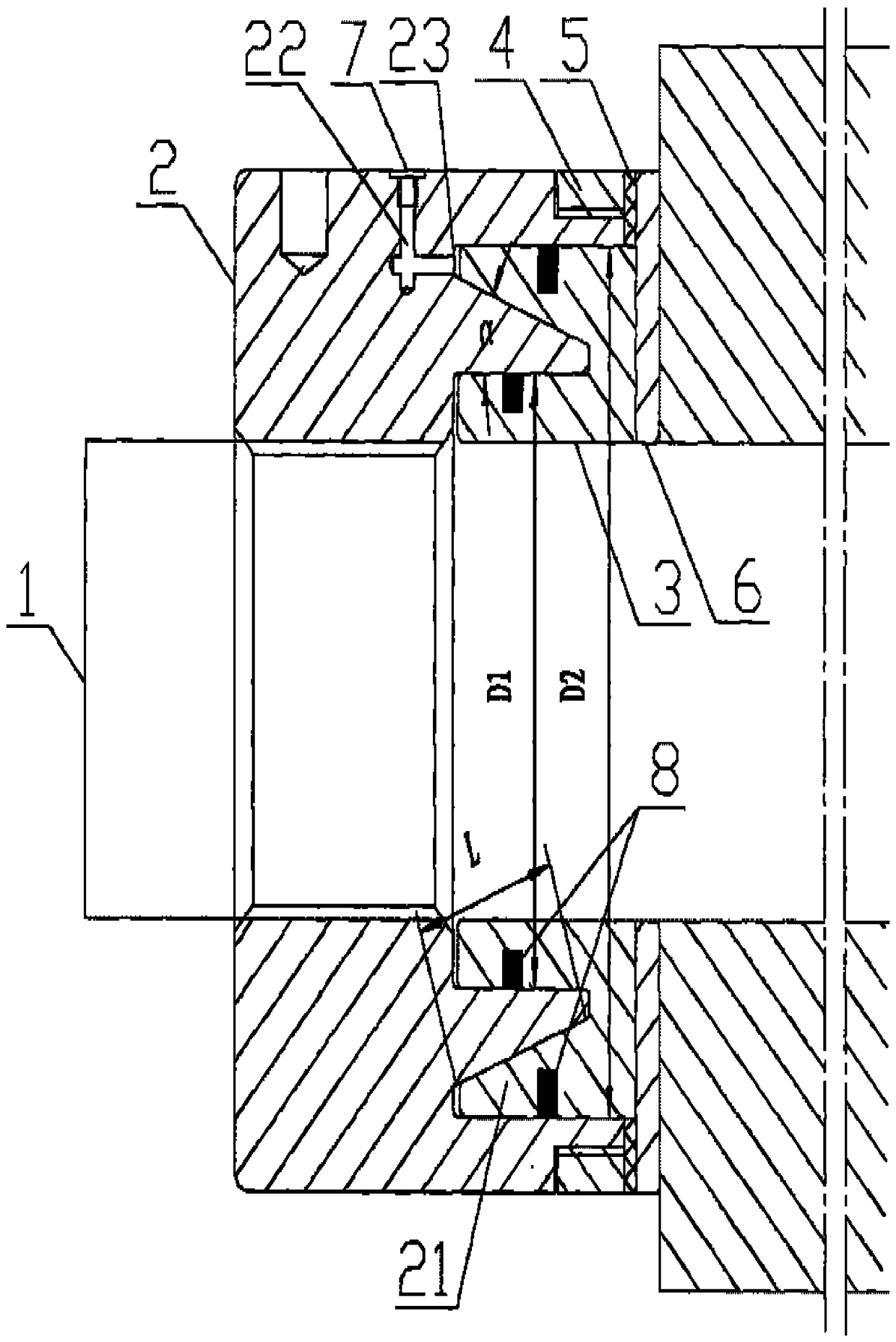

[0014] like figure 1 As shown, the piston-type high-pressure stretching hydraulic nut of the present invention includes a stretching nut 2, a high-pressure oil pipe interface 7, a piston 3, two annular seals 8, a lock nut 4, a half pad 5 and a nut washer 6, and the The inner ring of the tension nut 2 is stepped, and the stepped shoulder 23 of the tension nut protrudes a ring 21 along the axial direction. The inner ring of the ring 21 is parallel to the axial direction, and the outer ring of the ring 21 is An inclined plane, the thickness of the top of the wall of the ring 21 is smaller than the thickness of the bottom, the outer ring at one end of the ring 21 is provided with an external thread on the outer ring of the tension nut 2, and the side of the tension nut 2 is provided with the pull The channel 22 of the stepped shoulder 23 of the stretch nut, the channel 22 is connected to the high-pressure oil pipe interface 7, the lock nut 4 is locked on the external thread of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com