Detection methods of fosaprepitant dimeglumine raw material or preparation and impurity in fosaprepitant dimeglumine raw material or preparation

A detection method, the technology of fosaprepitant, applied in the direction of measuring device, material separation, analysis of materials, etc., can solve the problem of no detection method, affecting the quality of fosaprepitant dimeglumine, and the drug safety of patients, to achieve strong specific effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Use the following steps to detect:

[0071] (1) Take the reference substances of impurities A, B, C, D, E, F, and G respectively, mix acetonitrile and water with a volume ratio of 50:50, and dissolve these reference substances as a solvent, and prepare each 1mL containing impurities 5 μg of standard control solution;

[0072] (2) Take a sample of fosaprepitant dimeglumine, mix acetonitrile and water at a volume ratio of 50:50 and dissolve the sample as a solvent, and prepare a sample solution containing about 1.0 mg of the sample per 1 mL;

[0073] (3) Take part of the sample solution prepared in step (2) and part of the standard control solution of impurities A, B, C, D, E, F, G prepared in step (1), and mix the two evenly After obtaining the contrast sample solution;

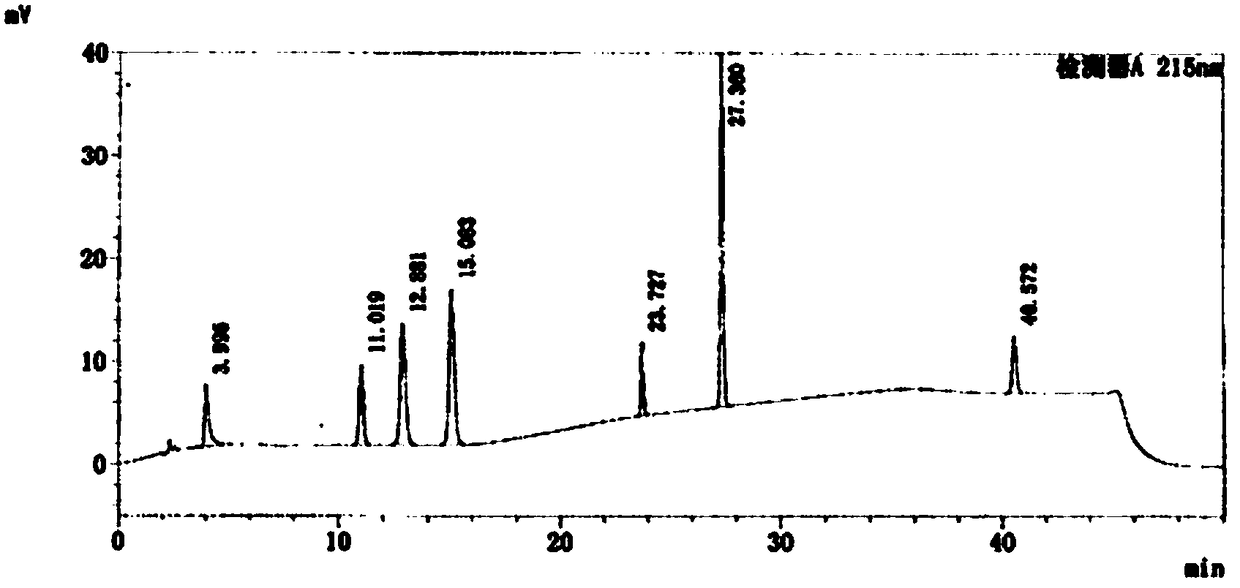

[0074](4) Perform HPLC detection on the obtained standard control solution, sample solution and comparison sample solution according to the following conditions, and record the chromatogram:

[0075]...

Embodiment 2

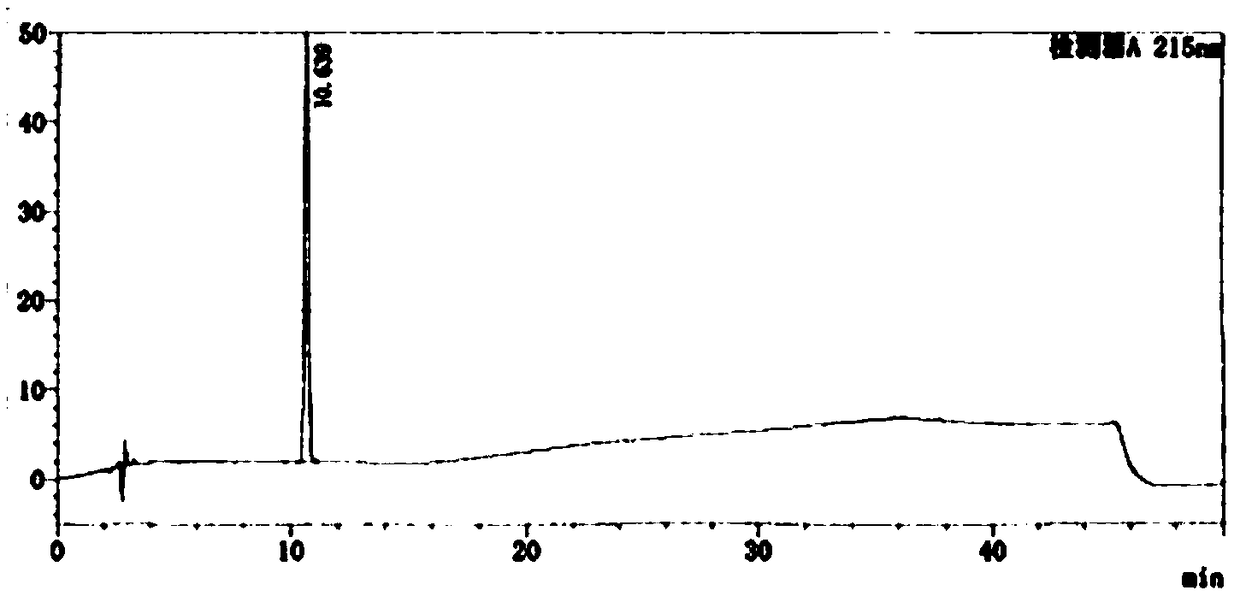

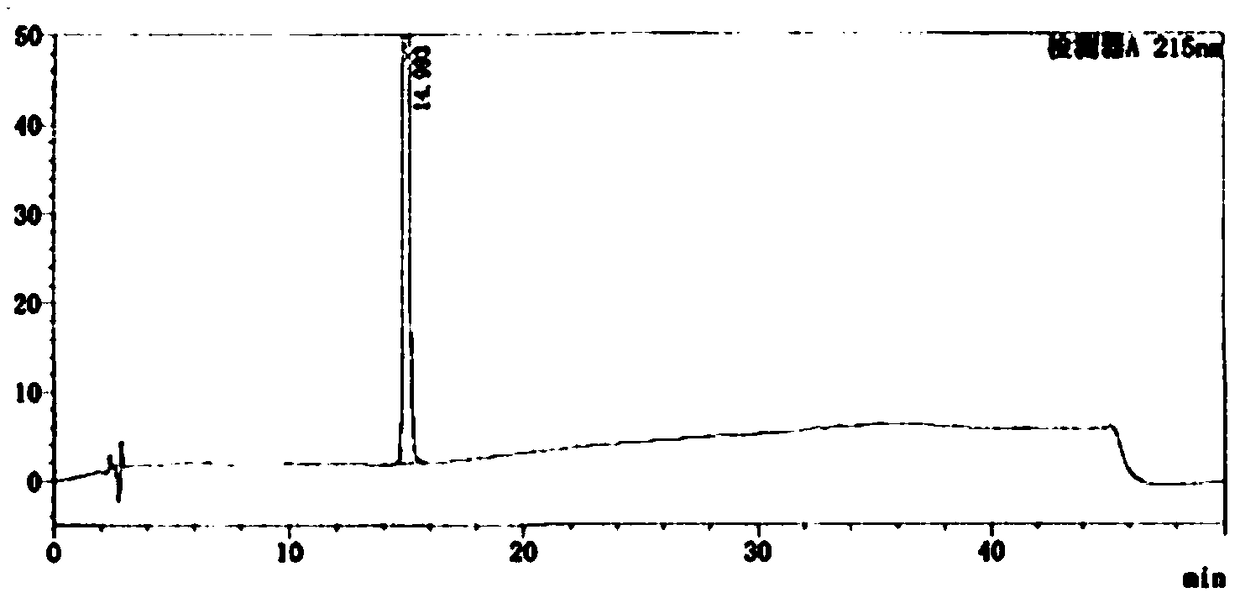

[0090] Use the following steps to detect:

[0091] (1) Take the reference substances of impurities A, B, C, D, E, F, G and fosaprepitant dipeglumine samples, mix acetonitrile and water with a volume ratio of 50:50 and dissolve them as a solvent to prepare Prepare the sample solution with Fosaprepitant Diglumine containing approximately 0.5 mg of impurities A, B, C, D, E, F, G and 1.0 mg of Fosaprepitant Diglumine sample per 1 mL;

[0092] (2) The obtained fosaprepitant dimeglumine prepared sample solution was subjected to HPLC detection according to the following conditions, and the chromatogram was recorded:

[0093] Chromatographic column: ACE C 18 , 4.6mm×250mm, 5µm;

[0094] Column temperature: 30°C; detection wavelength: 215nm;

[0095] Injection volume: 20 μL.

[0096] Mobile phase: 20mM ammonium dihydrogen phosphate buffer adjusted to pH 2.2 with phosphoric acid as mobile phase A, acetonitrile as mobile phase B, flow rate: 1.0ml / min;

[0097] Carry out gradient elu...

Embodiment 3

[0116] Example 3 Example of wavelength selection

[0117] Take a sample of fosaprepitant dipglumine, dissolve it with a solvent and dilute it to make a solution with a suitable concentration, and perform a spectral scan in the range of 200-400 nm according to the ultraviolet-visible spectrophotometry (Appendix IVA, Part Two of the Chinese Pharmacopoeia 2010 Edition), get attached Figure 12 The ultraviolet spectrogram shown shows that each impurity has a large absorption at 264 ± 3nm and the end region, and the absorption of each impurity at 264 ± 3nm is small, so 210nm and 215nm are selected for further comparison tests in the end region, and selected 215nm is used as the optimal wavelength.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com