Circuit breaker automatic detection equipment and detection method

An automatic detection and circuit breaker technology, applied in the direction of circuit breaker testing, etc., can solve the problems of large measurement error, low degree of automation, cumbersome operation, etc., and achieve the effect of high work efficiency and small error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

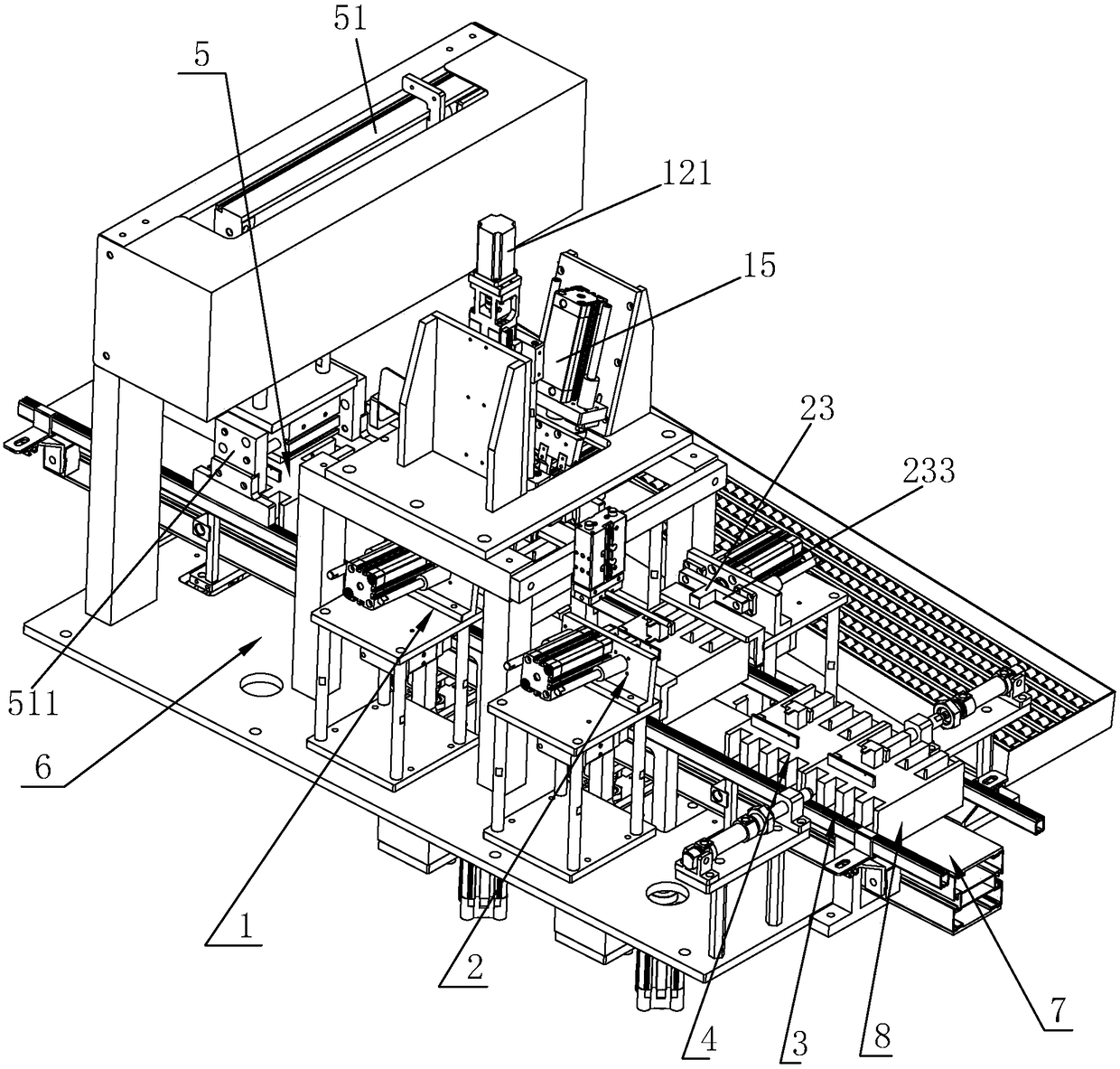

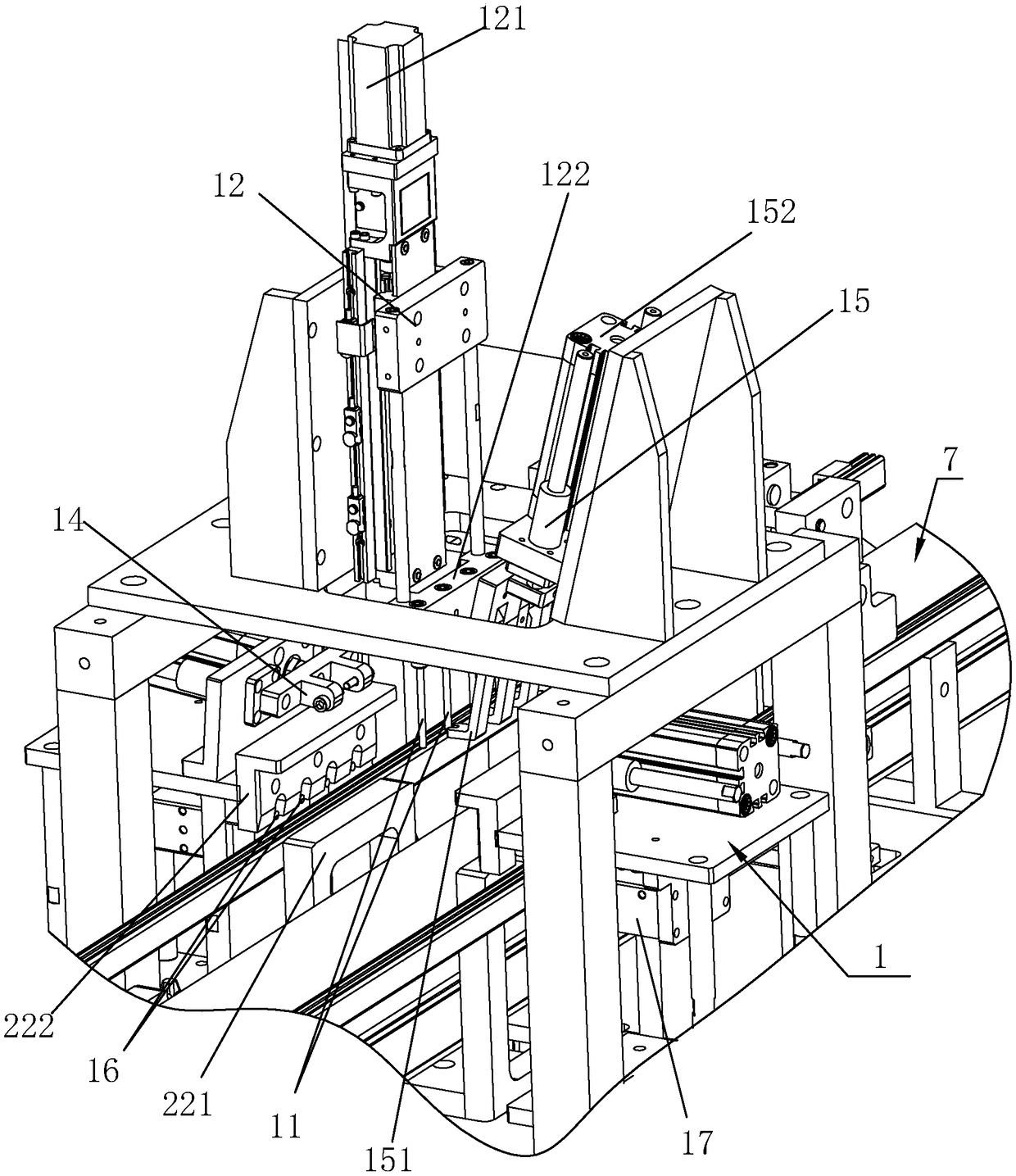

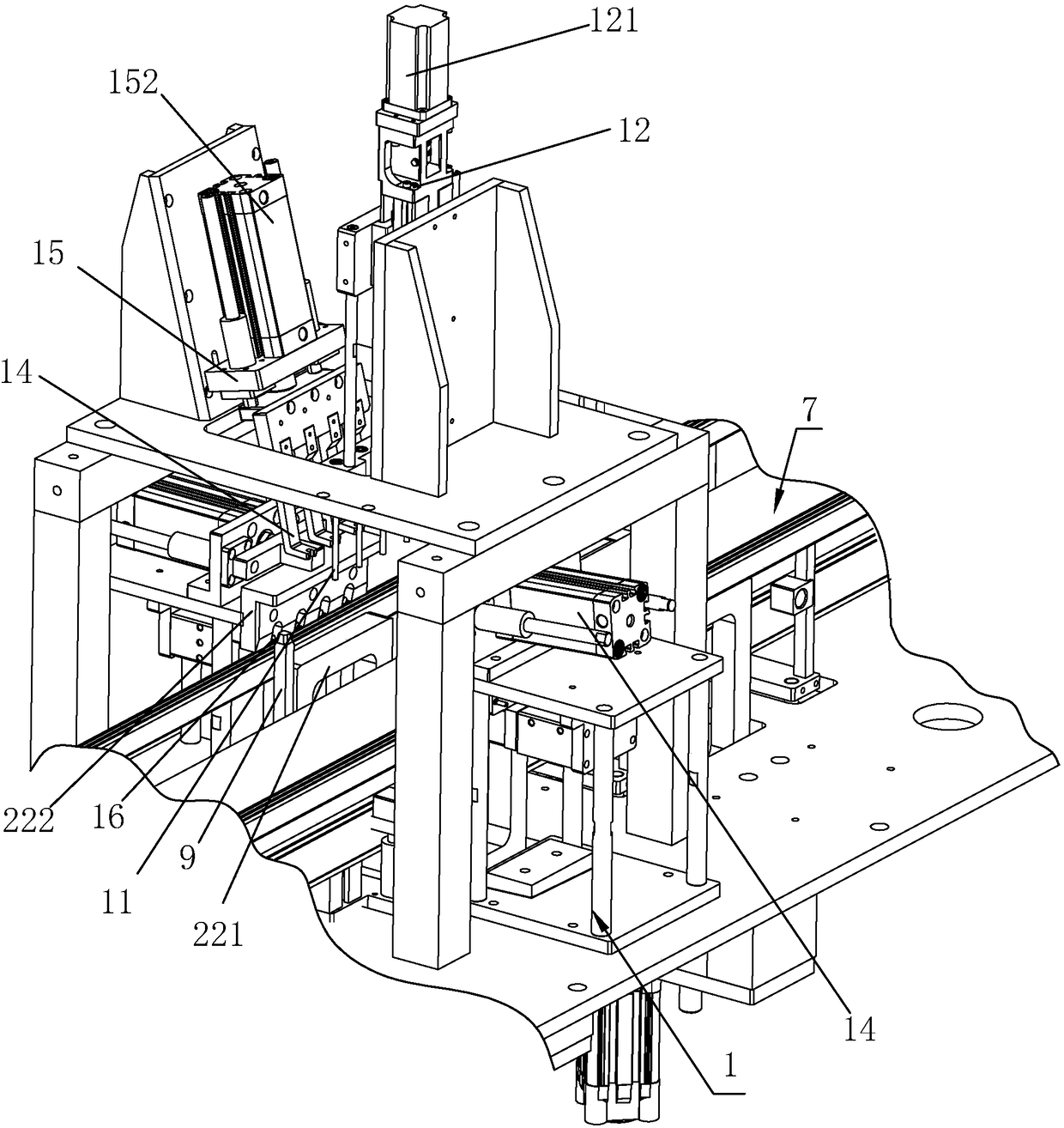

[0030] Such as Figure 1-Figure 3The automatic detection equipment for the circuit breaker shown includes a frame 6 and a transmission mechanism 7. The frame 6 is provided with a first station 1, and the first station 1 is provided with a circuit breaker 8 that is in phase with each moving contact of the circuit breaker 8. The corresponding open distance overtravel detection probe set 11, lifting mechanism 12, first clamping mechanism 13, first closing and opening mechanism 14, and analog static contact mechanism 15; the open distance overtravel detection probe set 11 is fixedly installed on The lifting mechanism 12 is driven by the lifting mechanism 12 to contact each moving contact. The first closing and opening mechanism 14 is fixedly installed on both sides of the first clamping mechanism 13 and drives the opening and closing of the switch of the circuit breaker 8, simulating the static contact The head mechanism 15 includes a spacer 151 simulating the shape of the static ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com