Supporting and hanging frame with adjustable elastic strength

A technology of elastic strength, support and hanger, applied in the direction of spring, spring/shock absorber, spring/shock absorber design characteristics, etc., can solve the problems of flexible adjustment, weak adaptability of spring support and hanger, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

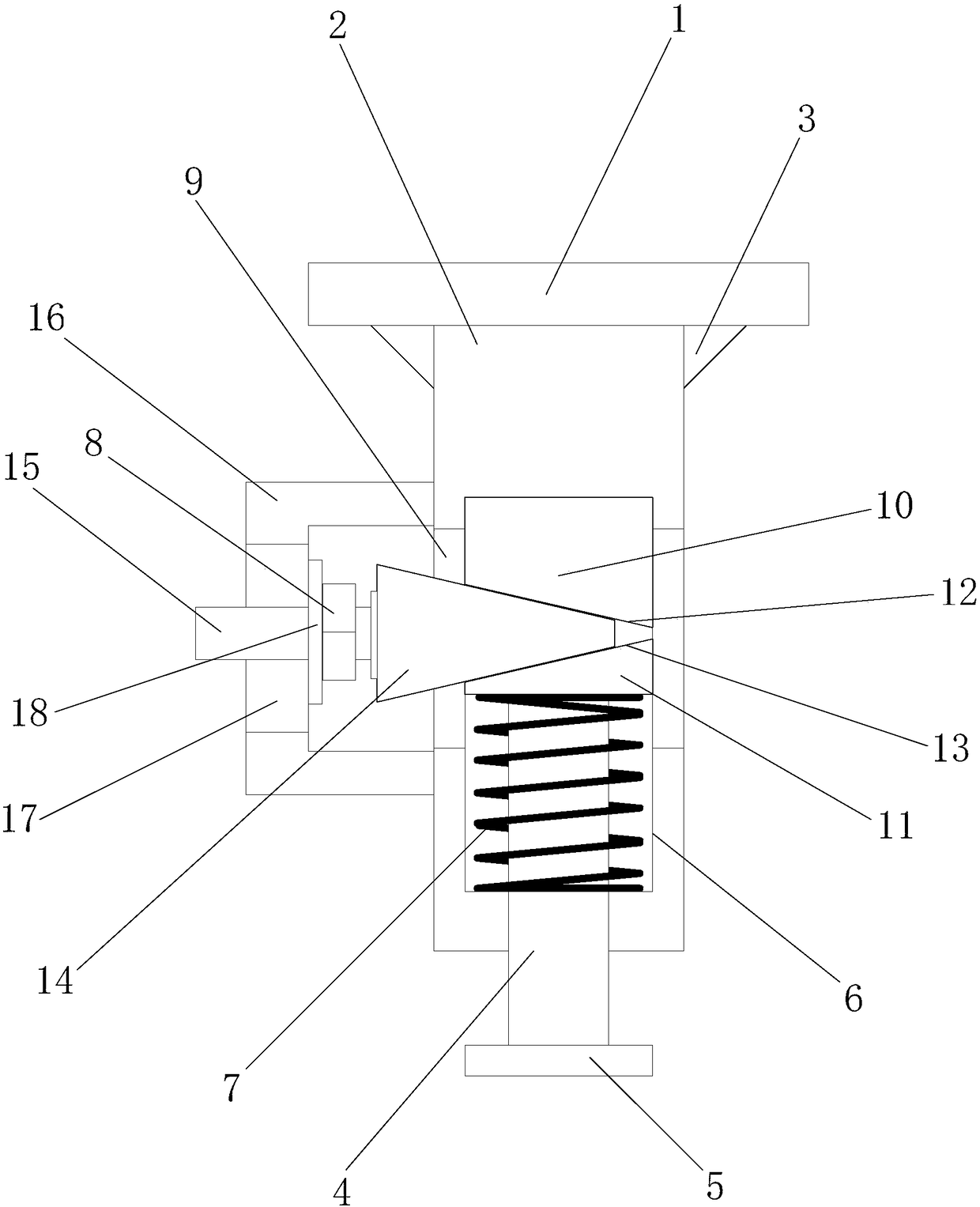

[0010] Such as figure 1 As shown, the present invention discloses a support and hanger with adjustable elastic strength, including: an upper mounting plate 1, a cylindrical shell 2, a boom 4, a lower mounting plate 5, an adjusting nut 8, a lower compression spring 7, an upper extrusion Plate 10, lower extruding plate 11, wedge-shaped insert 14 and adjusting screw rod 15; Cylindrical housing 2 is vertically fixedly installed on the underside of upper mounting plate 1; The upper extruding plate 10, the lower extruding plate 11 and the lower compression spring 7 are sequentially installed in the cylindrical installing cavity 6 from top to bottom; the lower side of the upper extruding plate 10 is provided with a lower slope surface 12. An upper slope surface 13 is provided on the upper side of the lower extrusion plate 11; the lower slope surface 12 and the upper slope surface 13 form a wedge-shaped socket; The insertion port 9; the wedge-shaped socket is located at the insertion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com