A vacuum sensor and test method for plateau use in new energy vehicles

A vacuum sensor and new energy vehicle technology, applied in vacuum gauges, instruments, measuring devices, etc., can solve the problems of affecting the service life of the sensor, power consumption, failure of the life of the pressure-transmitting chip, etc., and achieve high reliability and power saving. And the effect of long life and high leakage resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

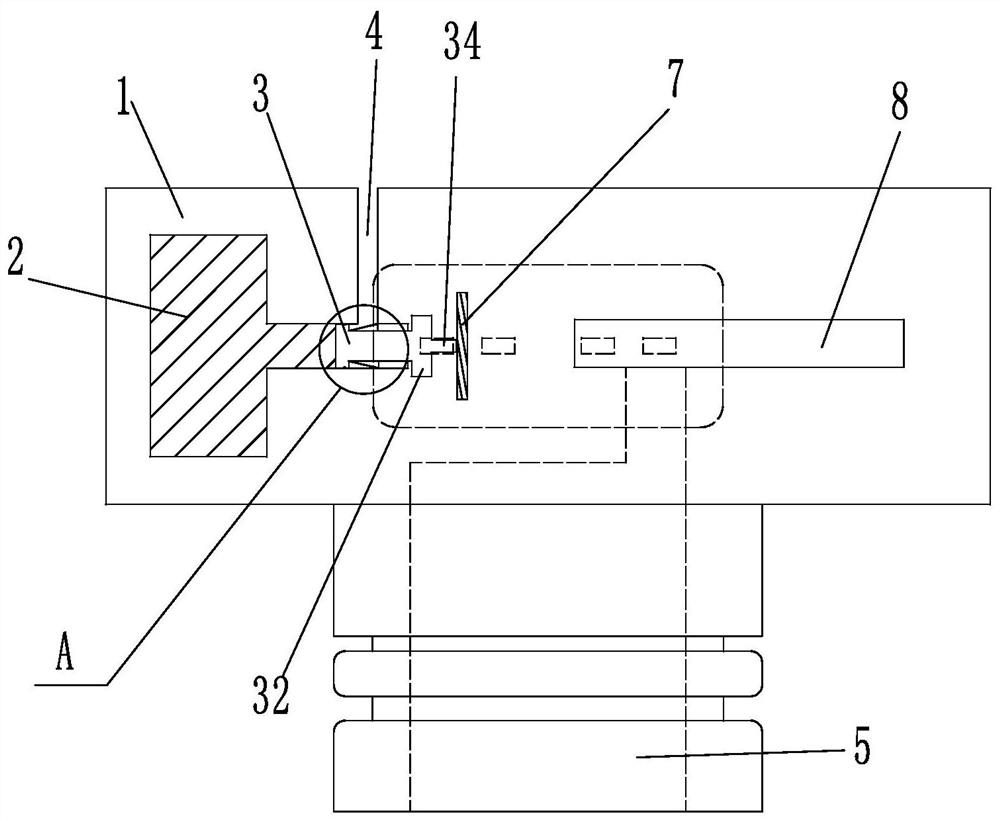

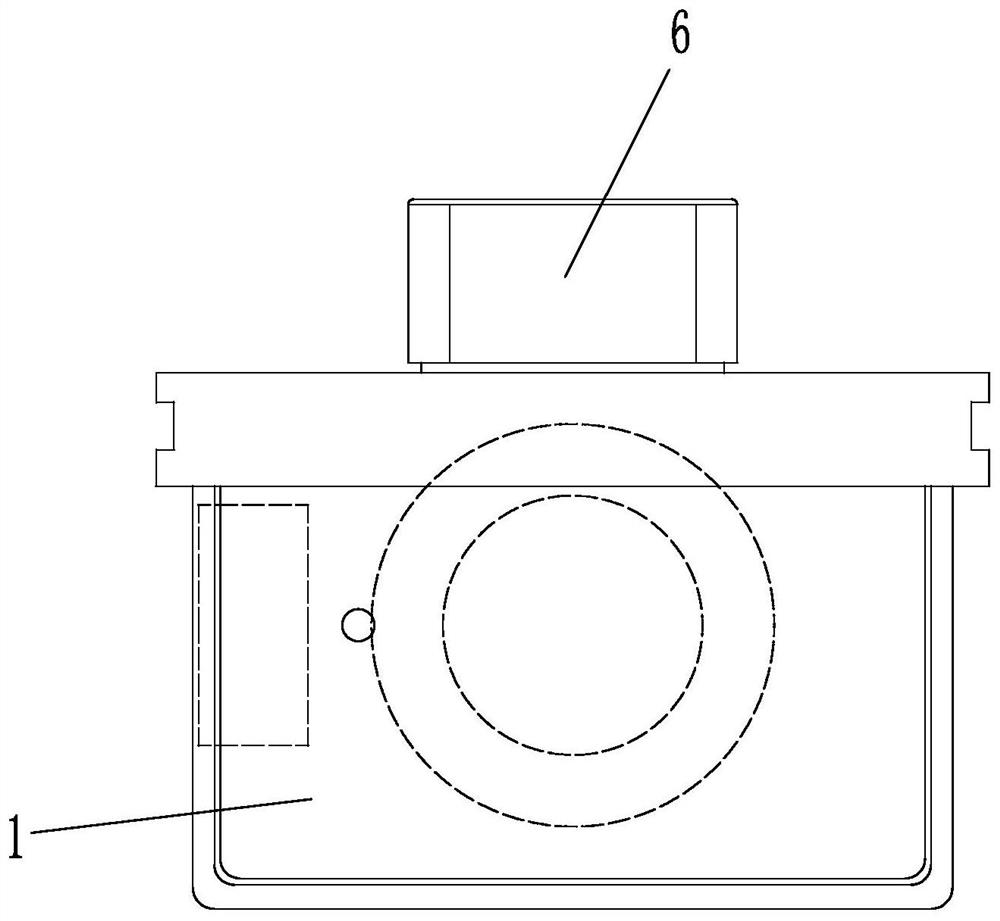

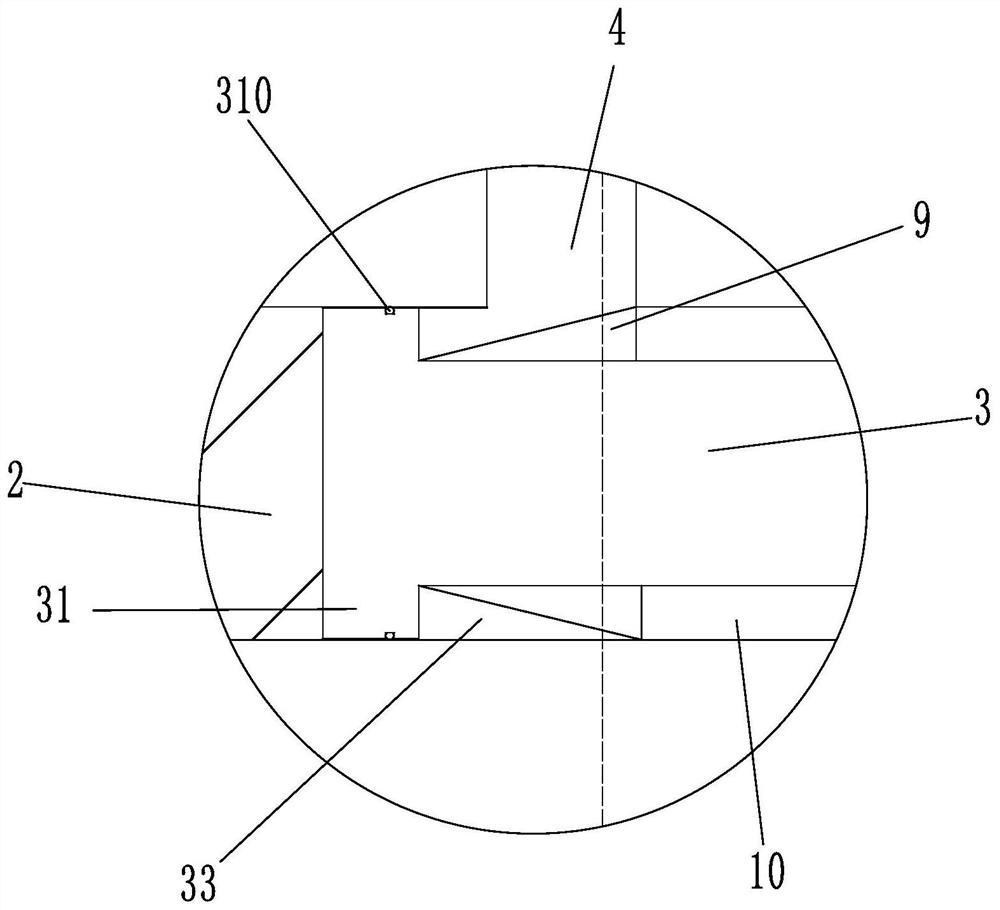

[0024] like Figure 1 to Figure 3 The illustrated embodiment is a plateau vacuum sensor for new energy vehicles, which is characterized in that it includes a housing 1 and an air chamber 2 inside the housing 1, the air chamber 2 and the outside are sealed with a piston 3, and the piston 3 It is slidably connected with the air chamber 2, and the housing 1 is provided with a slide hole matching the piston 3 on the wall of the air chamber 2, and the slide hole is a cylindrical through hole. The air chamber 2 includes a cavity with a longitudinal section of a square, the air chamber 2 is a cuboid, the sliding hole is coaxial with the air chamber 2, and the connecting section 31 of the piston 3 is located in the middle of the sliding hole. The piston 3 is provided with a connecting section 31 which slides and seals with the slide hole, and one end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com