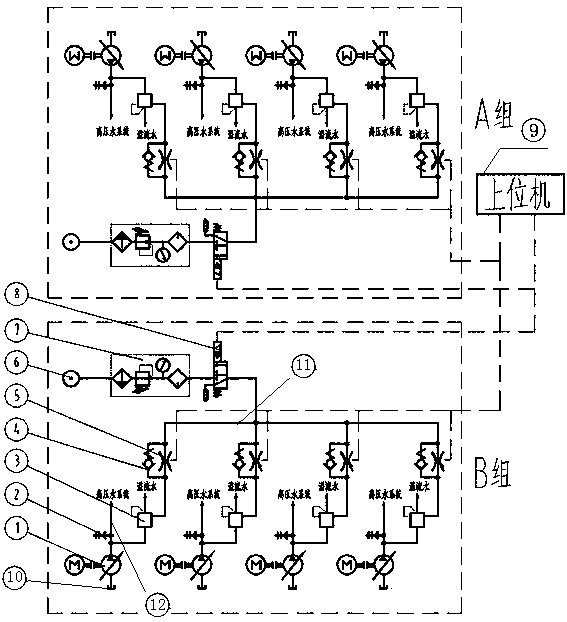

Ultrahigh pressure water parallel pressure regulation system and pressure regulation method

A pressure regulation system and ultra-high pressure technology, applied in earthwork drilling, mining equipment, tunnels, etc., can solve problems such as poor synchronization and difficult pressure adjustment, so as to improve stability and synchronization, improve construction efficiency, and ensure Effects on Reliability and Safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0025] Embodiment 2, a pressure regulation method of an ultra-high pressure water parallel pressure regulation system mounted on a TBM, comprising the following steps:

[0026] S1: The high-pressure water system is running, the electrical control parts are not running temporarily, the high-pressure water pump of the high-pressure water system is started at low pressure, and the water is discharged through the overflow port of the high-pressure pneumatic stop valve;

[0027] S2: Then the electrical control part runs, the upper computer controls the electromagnetic reversing valve and the proportional speed regulating valve to open, and the gas is passed into the high-pressure pneumatic stop valve, the gas pressure value is set to P1, and the force area on the gas side is a fixed value S1;

[0028] S3: With the increase of gas pressure P1, the liquid pressure value P2 of the high-pressure water in the second pipeline entering the high-pressure pneumatic stop valve also increases ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com