A method for detecting the symmetry of roll flat head

A detection method and symmetry technology, applied in the field of steel manufacturing, can solve the problems of inability to perform normal detection by conventional methods, excess capacity, and difficulty in controlling the details of the symmetry of the flat head, and achieve the effect of no calculation, intuitive data, and improved accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

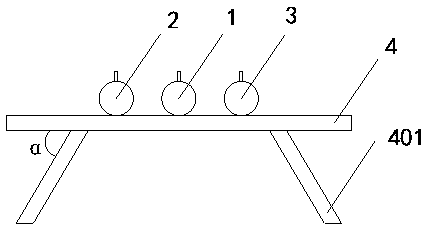

[0016] Such as figure 1 A detection device for the symmetry of a roll flat head as shown, comprising No. 1 dial gauge 1, No. 2 dial gauge 2, No. 3 dial gauge 3 and support 4, said No. 1 dial gauge 1, No. 2 dial gauge Dial gauge 2 and No. 3 dial gauge 3 are fixed above the bracket 4, No. 1 dial gauge 1 is located in the middle, No. 2 dial gauge 2 and No. 3 dial gauge 3 are set on both sides of No. 1 dial gauge 1, The distance between No. 2 dial gauge 2 and No. 1 dial gauge 1 is equal to the distance between No. 3 dial gauge 3 and No. 1 dial gauge 1. There are two support frames 401 below the support 4, and the support frames 401 are respectively connected to The bracket 4 has an included angle.

Embodiment 2

[0018] Referring to Example 1, the angle between the support frame 401 and the support frame 4 is 60°.

Embodiment 3

[0020] The detection method of the flat head symmetry of the roll: After determining the thickness of the flat head of the roll with the outer micrometer, use the detection device of the flat head symmetry of the roll, place it horizontally on the flat head of the roll, keep the dial indicator perpendicular to the surface of the roll, and then Shake left and right to find the 0 reference point in the No. 1 dial gauge, use this reference point as a reference line, use the depth gauge to match the vertical distance from the detection device to the flat head, and record data A; check the No. 2 reference point at the 0 reference point The readings of the dial gauge and the No. 3 dial gauge are used to understand the error in the horizontal direction, which side deviates more, after the measurement of the front section, move the instrument to the back section of the flat head, and check each thousand points at the 0 reference point The reading of the meter indicates the direction fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com