Transformer fault monitoring device and system

A technology of transformer fault and monitoring device, applied in transformer testing, measuring devices, instruments, etc., can solve problems such as affecting power supply, high failure rate of power transformers, and incompatible maintenance development trends.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

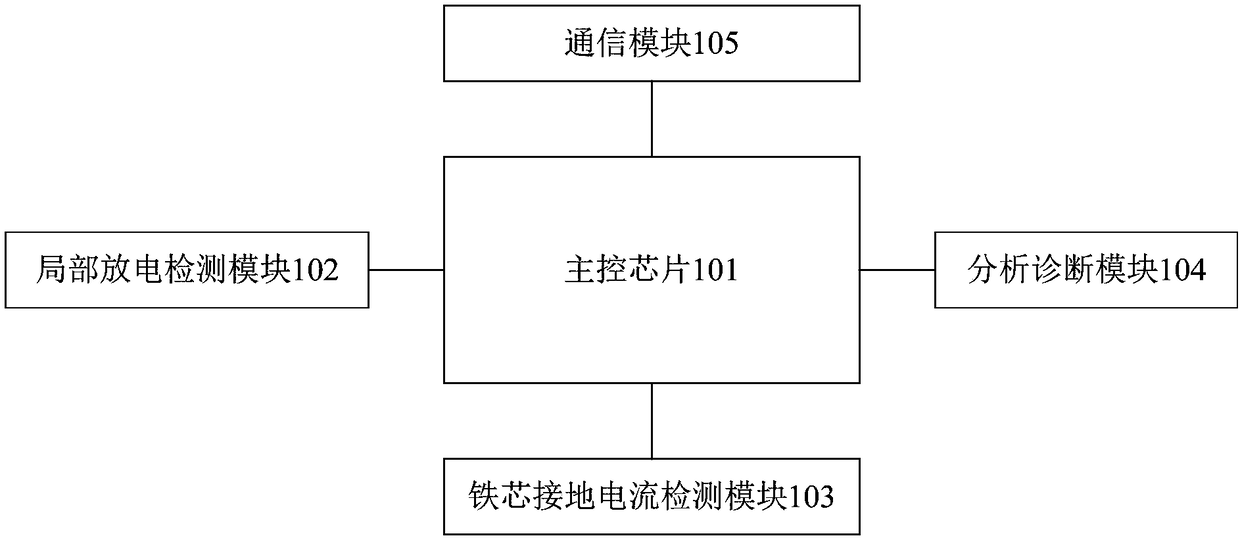

[0043] figure 1A schematic structural diagram of a transformer fault monitoring device provided in an embodiment of the present invention, as shown in figure 1 As shown, the transformer fault monitoring device includes a main control chip 101 , and a partial discharge detection module 102 , an iron core ground current detection module 103 , an analysis and diagnosis module 104 and a communication module 105 respectively connected to the main control chip 101 .

[0044] The partial discharge detection module 102 is used to detect partial discharge signals at different positions inside the transformer, and send the partial discharge signals to the main control chip 101 . The core ground current detection module 103 is used to detect the ground leakage current of the transformer core, and send the ground leakage current to the main control chip 101 . The main control chip 101 is used to receive the partial discharge signal and the ground leakage current, and send them to the ana...

Embodiment 2

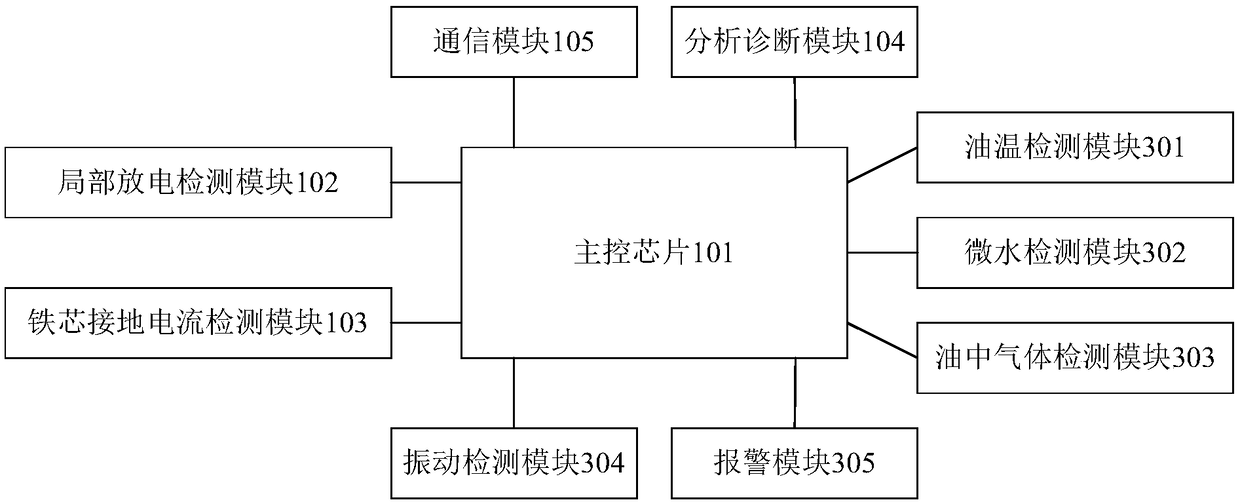

[0062] Figure 4 A structural schematic diagram of a transformer fault monitoring system provided by an embodiment of the present invention, as shown in Figure 4 As shown, the transformer fault monitoring system includes a monitoring terminal 42 and a transformer fault monitoring device 41 as in the first embodiment above. The transformer fault monitoring device 41 is communicatively connected with the monitoring terminal 42 .

[0063]In the embodiment of the present invention, the transformer fault monitoring device includes a main control chip, and a partial discharge detection module, an iron core ground current detection module, an analysis and diagnosis module, and a communication module respectively connected to the main control chip; the partial discharge detection module is used to detect transformer Partial discharge signals at different positions inside, and send the partial discharge signals to the main control chip; the core grounding current detection module is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com