Intelligent unattended vending machine and goods discharge method

A vending machine, intelligent technology, applied in the direction of coinless or similar appliances, instruments, coin-operated equipment for distributing discrete items, etc., can solve the problem of low efficiency of automatic delivery in the receiving and delivery structure, and delivery Unreasonable mouth height and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

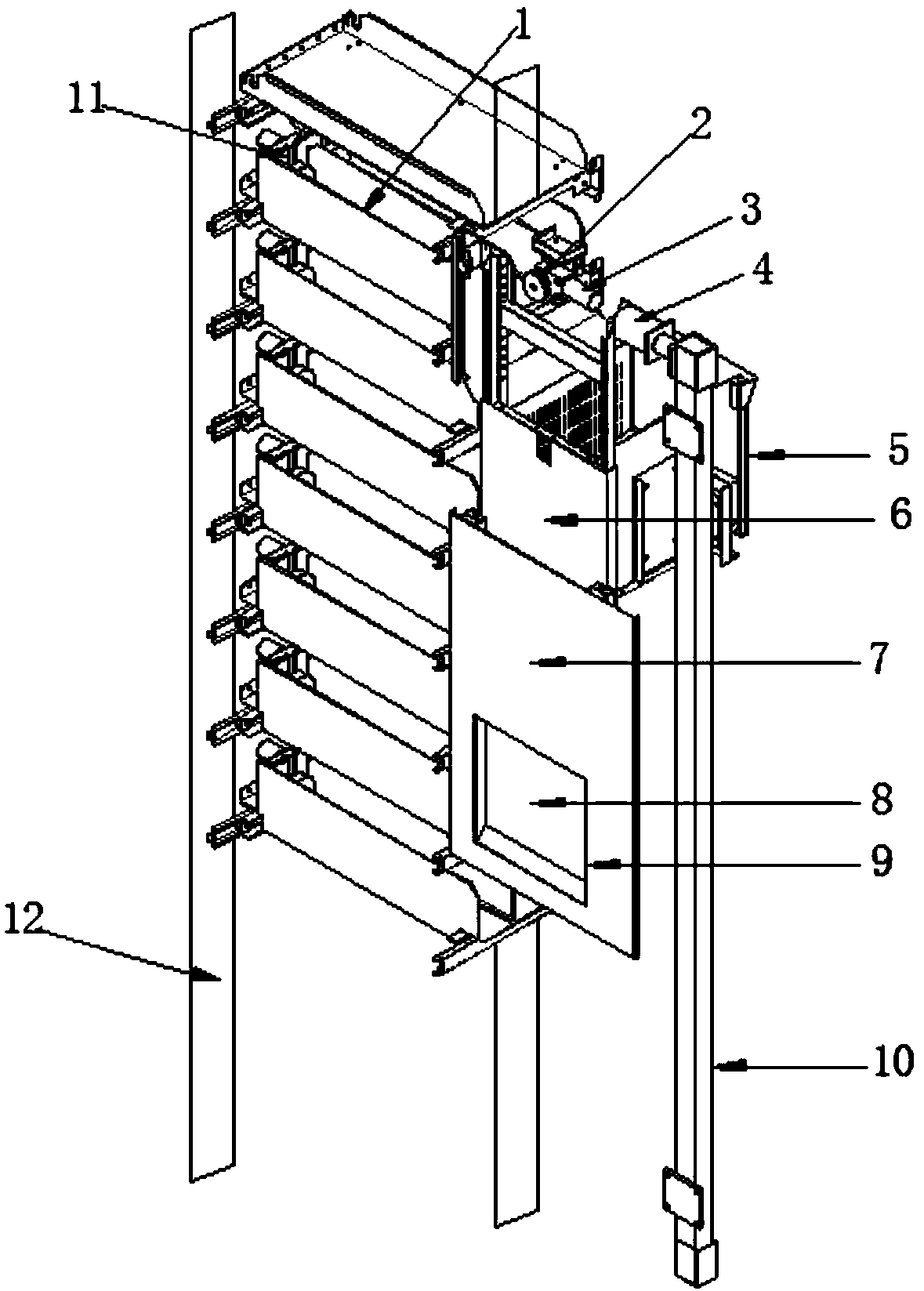

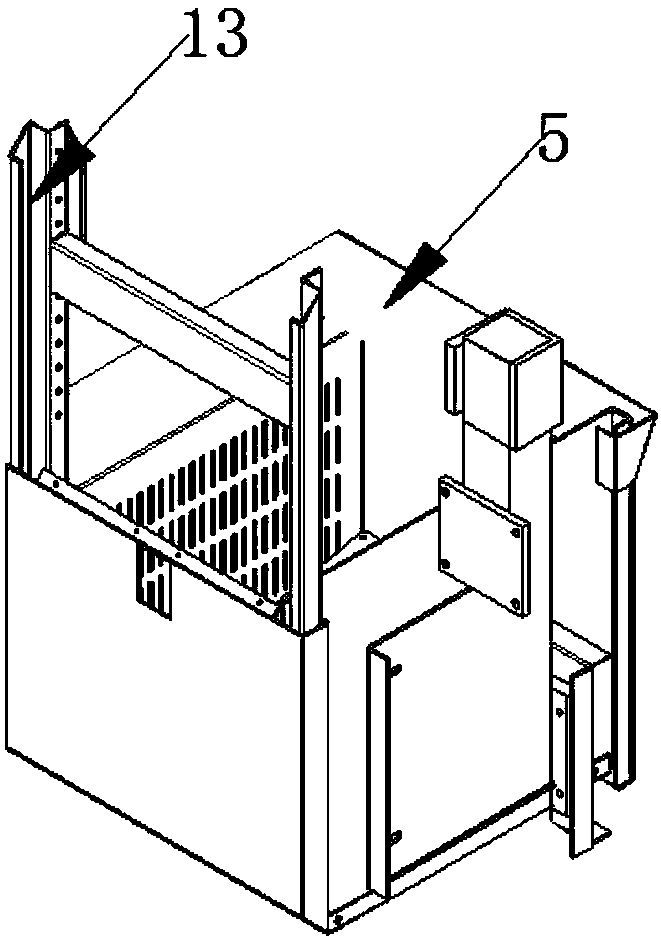

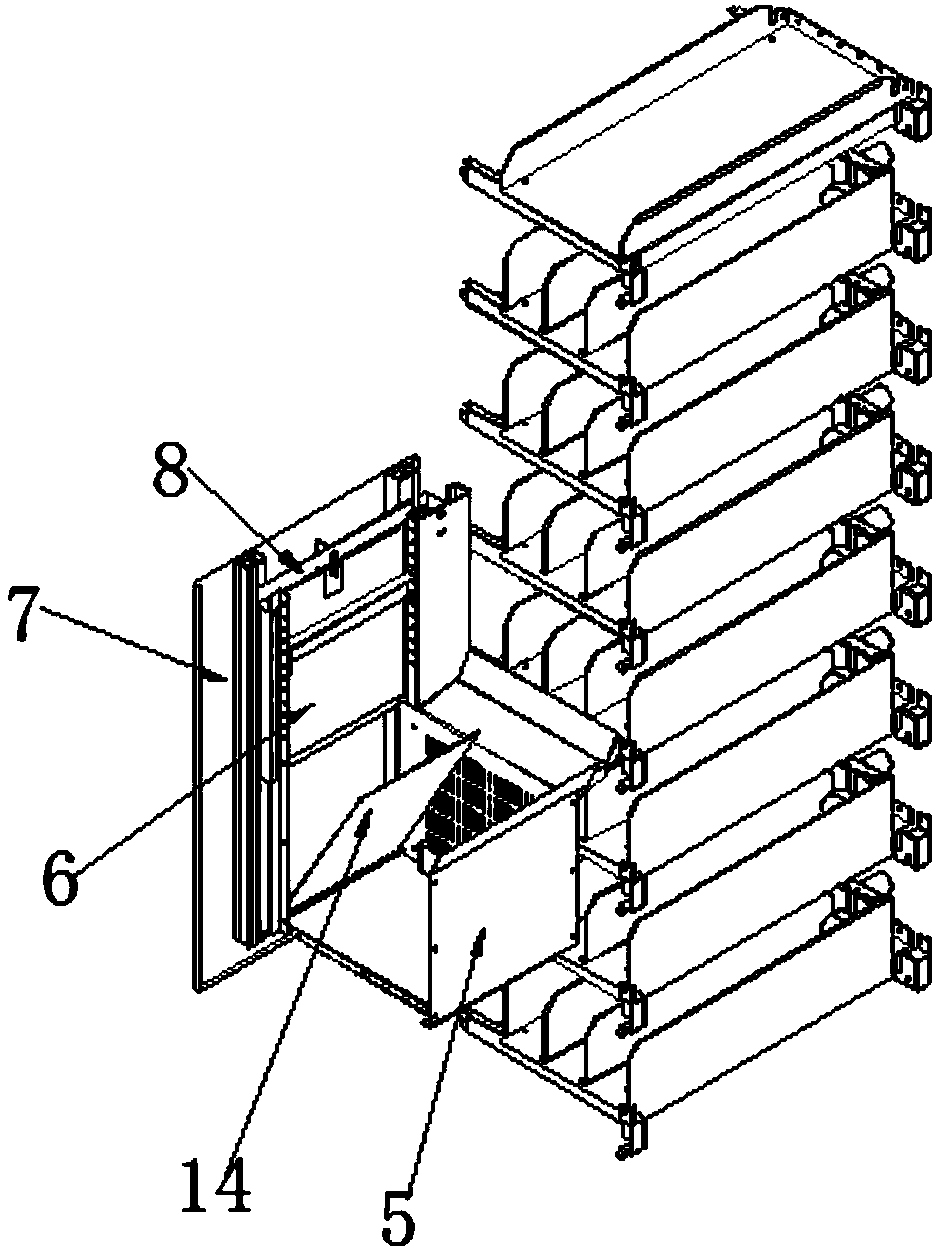

[0035] The intelligent unmanned vending machine of this example includes a frame 12, a drawer 1 is fixed by bolts between the two frames 12, and a pusher motor is fixed by bolts at one end of the cargo lane of the drawer 1 11. A reduction motor 3 is fixed by bolts on the upper end of the frame 12, a rotating pulley 2 is screwed on the reduction motor 3, and a movable pulley is arranged at the end of the drawer 1 far away from the pushing motor 11. The cargo bucket 5 moving vertically along the lifting track 10 is fixed with a stepper motor 4 by bolts at the upper end of the lifting track 10, and a guide frame 13 is fixed by bolts in front of the bucket 5. A cargo door panel 6 is arranged on the guide frame 13, and a delivery opening sealing plate 7 is fixed between the frame 12 and the lifting rail 10 by bolts, and the lower part of the delivery opening sealing plate 7 A delivery port 9 is pierced, and a delivery door panel 8 is arranged to slide vertically in the delivery por...

Embodiment 2

[0050] The intelligent unmanned vending machine of this example includes a frame 12, a drawer 1 is fixed by bolts between the two frames 12, and a pusher motor is fixed by bolts at one end of the cargo lane of the drawer 1 11. A reduction motor 3 is fixed by bolts on the upper end of the frame 12, a rotating pulley 2 is screwed on the reduction motor 3, and a movable pulley is arranged at the end of the drawer 1 far away from the pushing motor 11. The cargo bucket 5 moving vertically along the lifting track 10 is fixed with a stepper motor 4 by bolts at the upper end of the lifting track 10, and a guide frame 13 is fixed by bolts in front of the bucket 5. A cargo door panel 6 is arranged on the guide frame 13, and a delivery opening sealing plate 7 is fixed between the frame 12 and the lifting rail 10 by bolts, and the lower part of the delivery opening sealing plate 7 A delivery port 9 is pierced, and a delivery door panel 8 is arranged to slide vertically in the delivery por...

Embodiment 3

[0054] The intelligent unmanned vending machine of this example includes a frame 12, a drawer 1 is fixed by bolts between the two frames 12, and a pusher motor is fixed by bolts at one end of the cargo lane of the drawer 1 11. A reduction motor 3 is fixed by bolts on the upper end of the frame 12, a rotating pulley 2 is screwed on the reduction motor 3, and a movable pulley is arranged at the end of the drawer 1 far away from the pushing motor 11. The cargo bucket 5 moving vertically along the lifting track 10 is fixed with a stepper motor 4 by bolts at the upper end of the lifting track 10, and a guide frame 13 is fixed by bolts in front of the bucket 5. A cargo door panel 6 is arranged on the guide frame 13, and a delivery opening sealing plate 7 is fixed between the frame 12 and the lifting rail 10 by bolts, and the lower part of the delivery opening sealing plate 7 A delivery port 9 is pierced, and a delivery door panel 8 is arranged to slide vertically in the delivery por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com