Special tool jig for combining and hoisting end beams of multifunctional aluminum electrolysis crane

A technology of combined hoisting and tooling, applied in cranes, walking bridge cranes, transportation and packaging, etc., can solve problems such as difficulty in accurately determining the center position of end beams, difficulty in manual adjustment at high altitude, and affecting the service life of wire ropes. , to achieve the effect of easy assembly and disassembly, shorten assembly time, and improve assembly quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

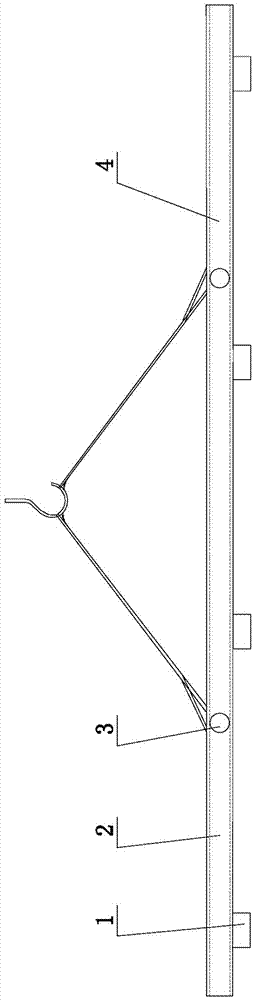

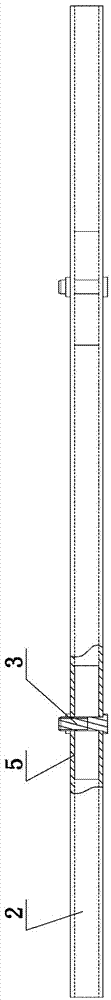

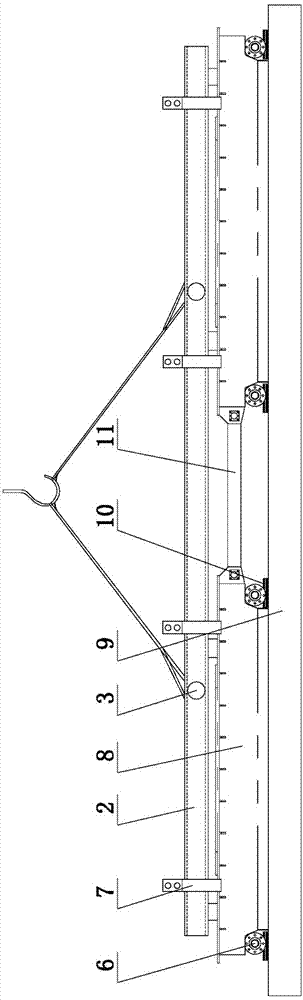

[0025] The present invention includes a positioning base 9, a connecting device 11, a hoisting pole 4 and at least two locking clips 7, and is characterized in that: the positioning base 9 is provided with a positioning track 10 corresponding to the traveling wheel 6 of the end beam 8; The lifting pole 4 includes a pole 2, and two sides of the pole 2 are provided with hoisting shafts 3, and the top of the pole 2 is provided with a hoisting hole 5 corresponding to the hoisting shaft 3; the locking clip 7 includes two symmetrical A card body 13 is provided between the two card bodies 13 with a card frame 15 which is matched with the shoulder body 2. The lower end of the card body 13 is provided with a hook 12 corresponding to the upper end of the end beam 8, and the upper ends of the two card bodies 13 are connected by a connecting piece 14. The connecting device 11 includes a connecting beam, and both ends of the connecting beam are provided with a connecting head 16 that can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com