Modeling method for variable-ratio racks in thickened-sector rack pair of variable-ratio steering gear

A modeling method and steering gear technology, applied in the direction of components with teeth, instruments, belts/chains/gears, etc., can solve the problem of poor modeling accuracy, difficult to identify and determine the point of variable ratio tooth profile, and inaccurate solutions of meshing equations. only question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

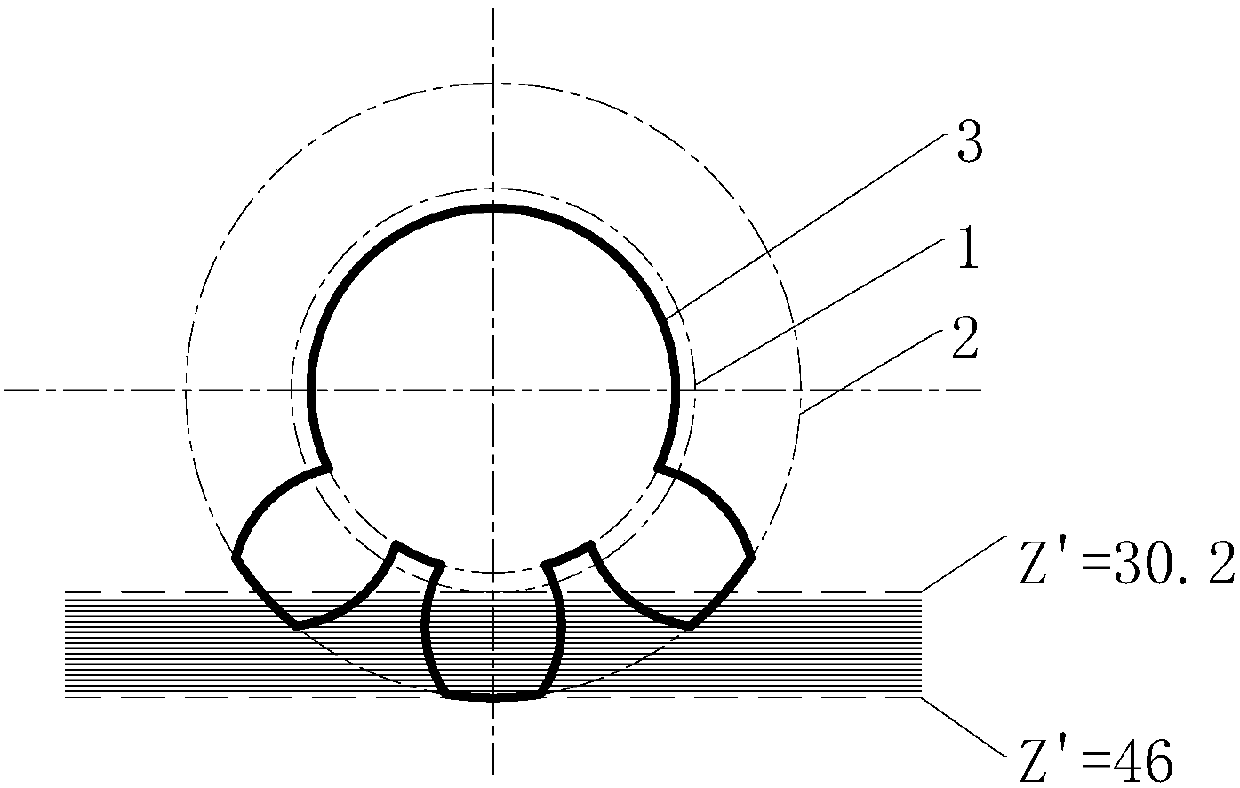

[0019] In a specific embodiment of the present invention, a method for modeling a variable ratio rack in a thickened sector rack pair of a recirculating ball variable ratio steering gear is provided, including the following steps:

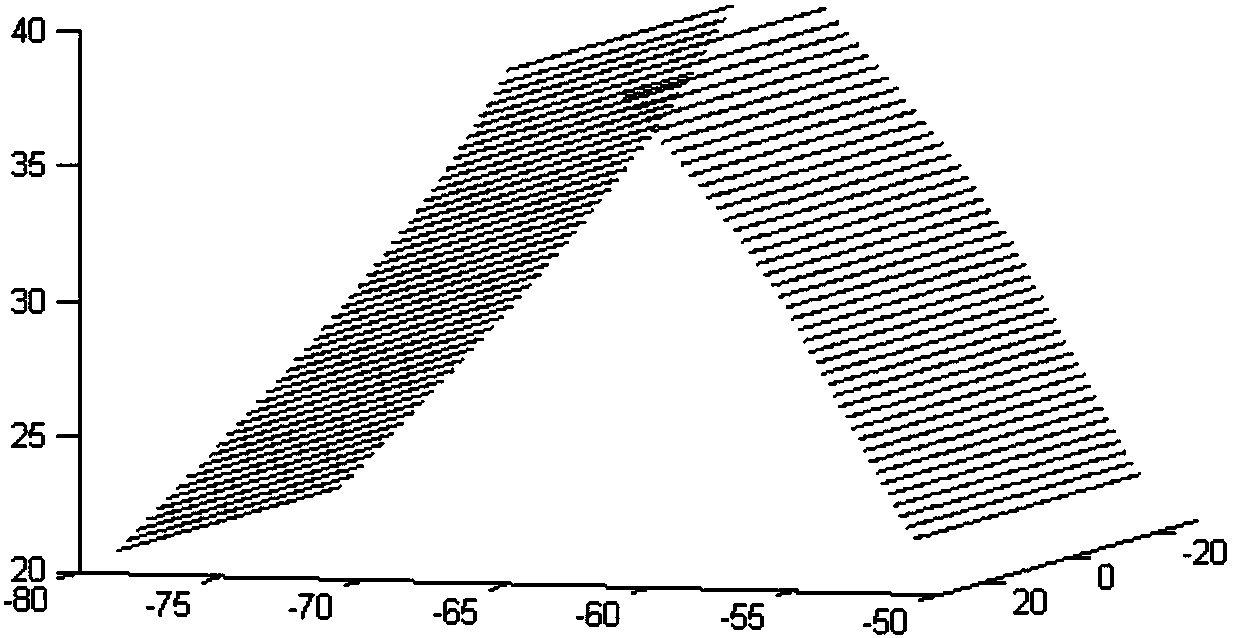

[0020] S1: In a radial cross-sectional plane of the thickened involute tooth fan, between the base circle of the tooth fan and the tangent of the tooth top circle parallel to the tooth side of the variable ratio rack, a The set of straight lines formed by the straight lines in the length direction of the rack, and two adjacent straight lines are equally spaced.

[0021] The straight lines in the set of straight lines are shown in formula (1):

[0022] z'=z' i ,z' i ∈[-R a -R b ] i=0,1,2,...,n (1)

[0023] Among them, R b is the radius of the base circle of the tooth sector; R a is the radius of the addendum circle in the section plane.

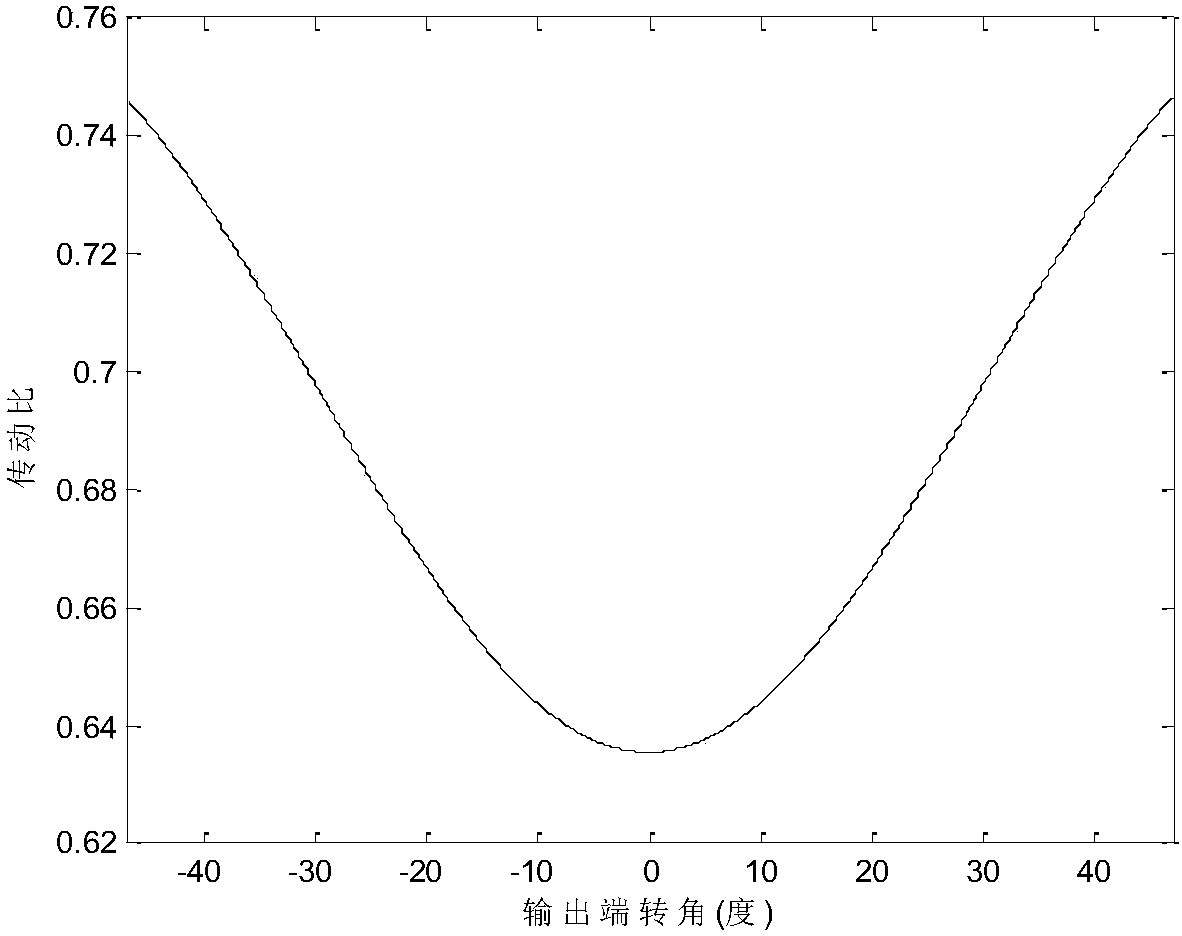

[0024] S2: Looking from the large end of the toothed sector to the small end, the variable ratio rack i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com