Device and method for measuring torque and torsion angle of steel wire rope

A measuring device and steel wire rope technology, applied in the field of steel wire rope detection, can solve the problems of the internal structure of the measuring device and the description of the measuring method, the inability to realize the one-time measurement of the steel wire rope, etc., and achieve the effects of simple and clear operation process, wide applicability, safe and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

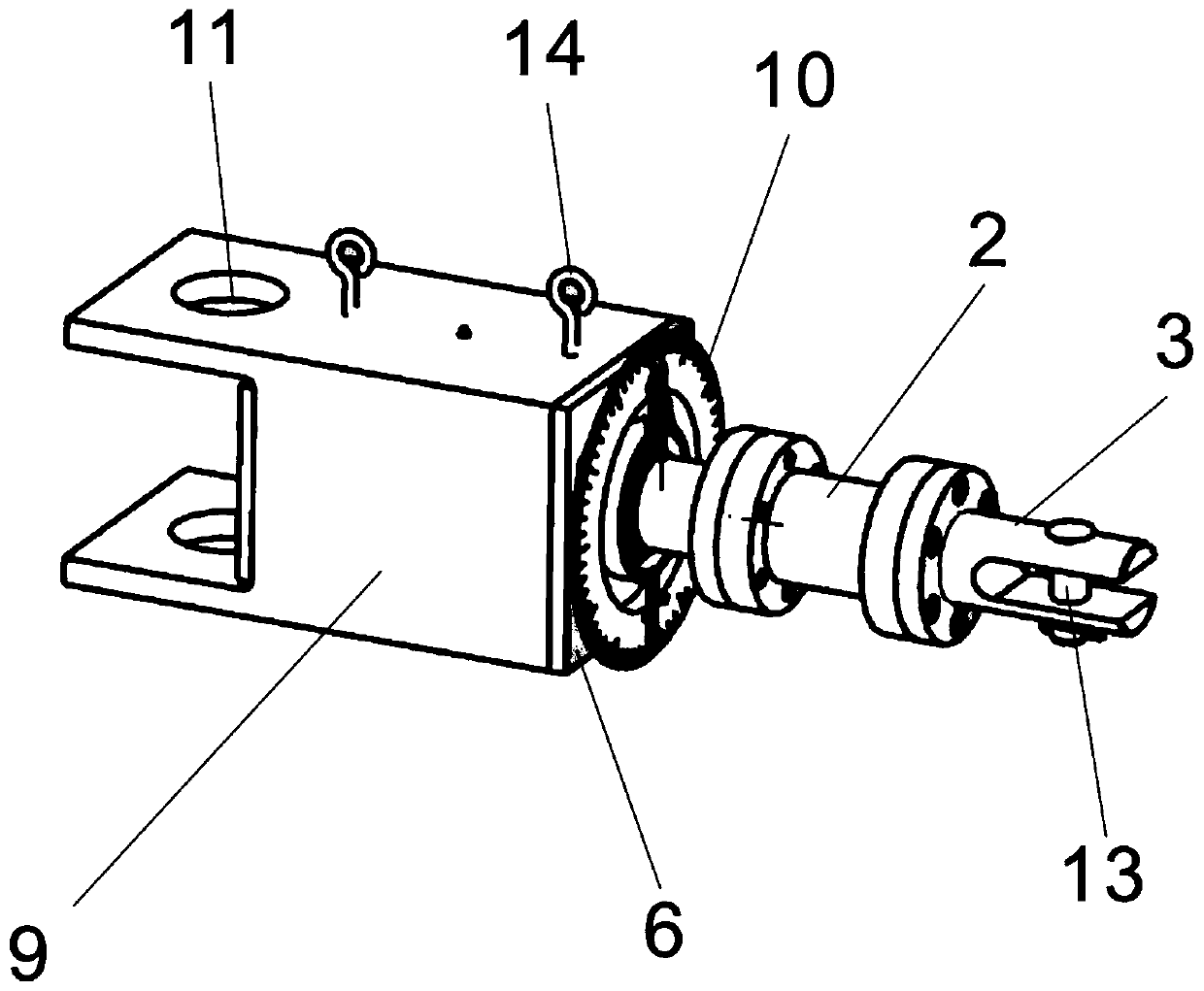

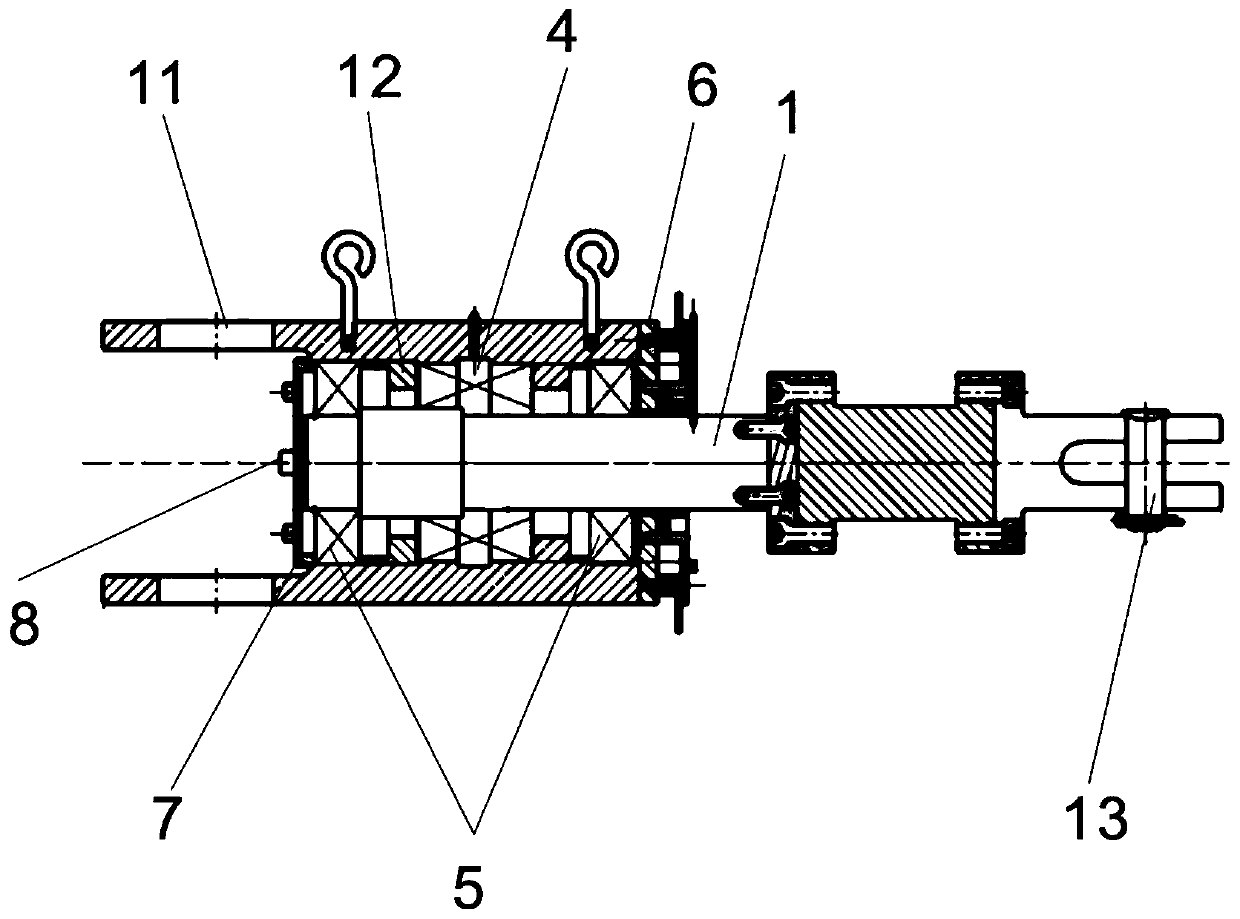

[0034] A kind of steel wire rope torque and torsion angle measuring device of the present invention, such as figure 1 with figure 2 As shown, it includes the first main shaft 1, the multi-axial dynamic torque sensor 2 and the second main shaft 3 connected in sequence and on the same axis. The second main shaft 3 is "U" shaped, and the opening of the second main shaft 3 is set far away from One end of the multiaxial dynamic torque sensor 2, the opening of the second main shaft 3 is provided with a positioning pin 13, the positioning pin 13 is perpendicular to the axis of the second main shaft 3, and the positioning pin 13 closes the opening of the second main shaft 3, the first The main shaft 1 is provided with a two-way thrust ball bearing 4, and both sides of the two-way thrust ball bearing 4 are provided with deep groove ball bearings 5, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com