Spare parts warehouse layout method and system

A layout method and warehouse technology, applied in the field of spare parts warehouse layout method and system, can solve problems such as deviation of results from reality, unstable optimal solution, increase in calculation time, etc., and achieve the effect of optimizing the location and number of locations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Features and exemplary embodiments of various aspects of the invention will be described in detail below. The following description covers numerous specific details in order to provide a thorough understanding of the present invention. It will be apparent, however, to one skilled in the art that the present invention may be practiced without some of these specific details. The following description of the embodiments is only to provide a clearer understanding of the present invention by showing examples of the present invention. The present invention is by no means limited to any specific configuration set forth below, but covers any modification, substitution and improvement of related elements or components without departing from the spirit of the invention.

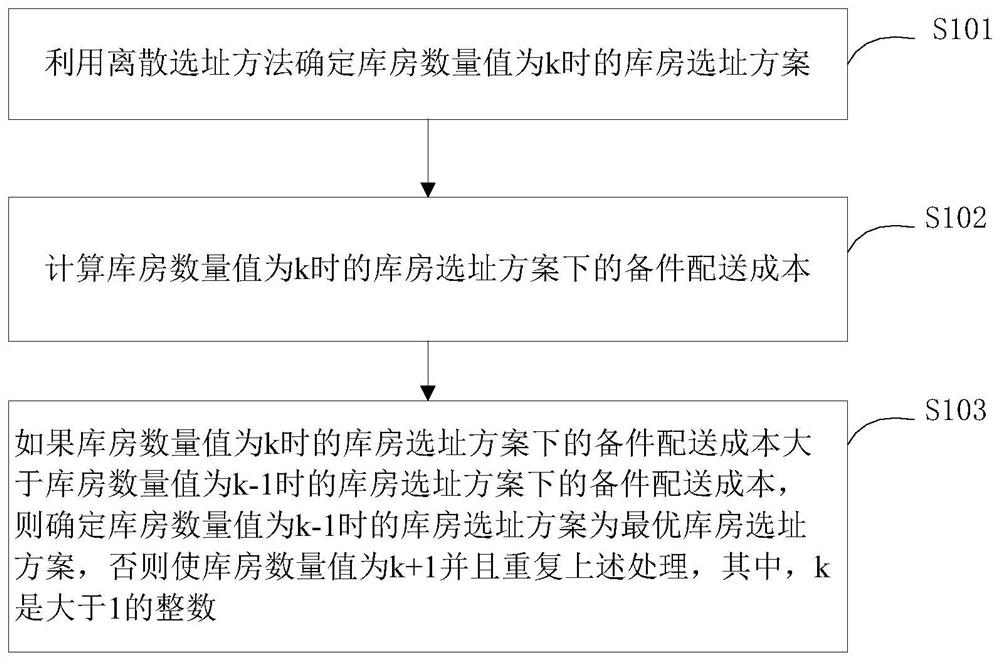

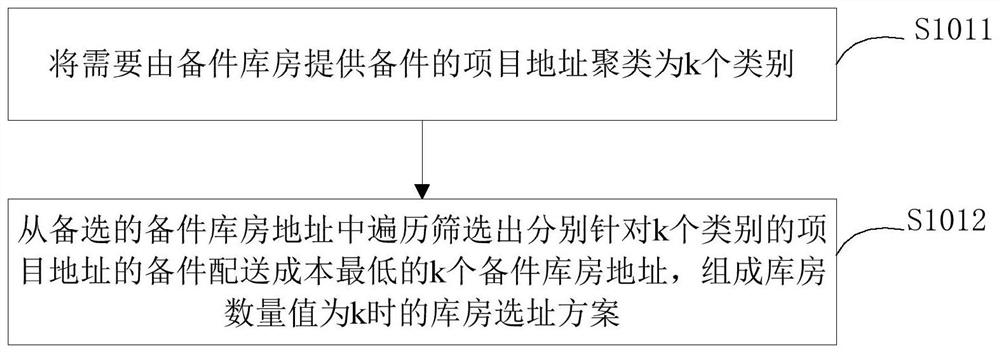

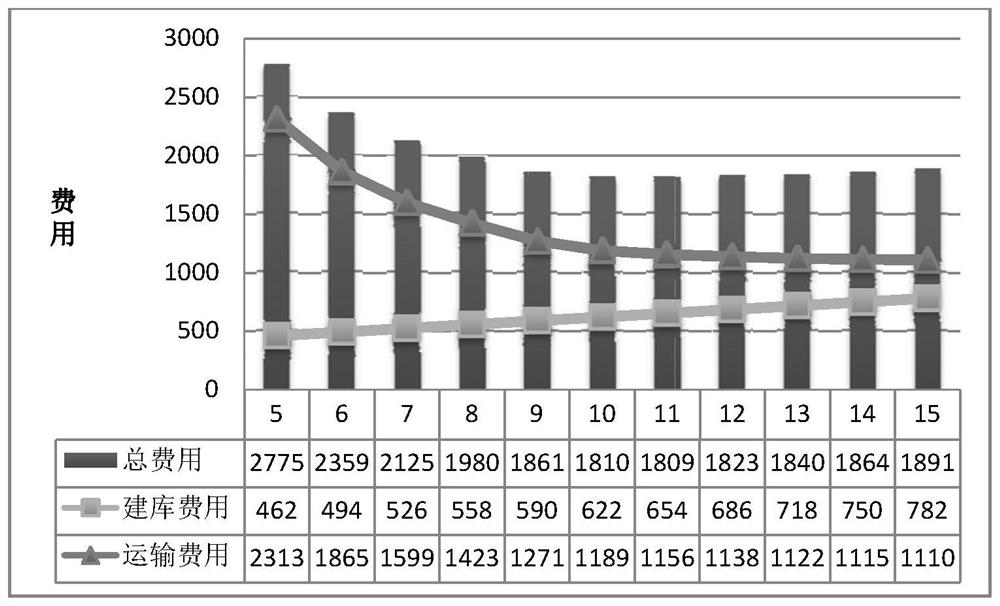

[0028] The present invention proposes a novel spare parts warehouse layout method and system, by taking the spare parts distribution cost as the optimization target and taking the location quantity and location...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com