Multi-camera calibration method based on the principle of minimum optical path and transparent glass calibration plate

A technology of transparent glass and calibration method, which is applied in image data processing, image analysis, instruments, etc., can solve the problems of difficult control of manufacturing precision, inaccurate alignment of calibration patterns on both sides, and affect the accuracy of calibration results, etc., to achieve simplification and optimization Parameter process, improving accuracy, effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The technical solutions in the embodiments of the present invention will be described clearly and in detail below with reference to the drawings in the embodiments of the present invention. The described embodiments are only some of the embodiments of the invention.

[0045] The technical scheme that the present invention solves the problems of the technologies described above is:

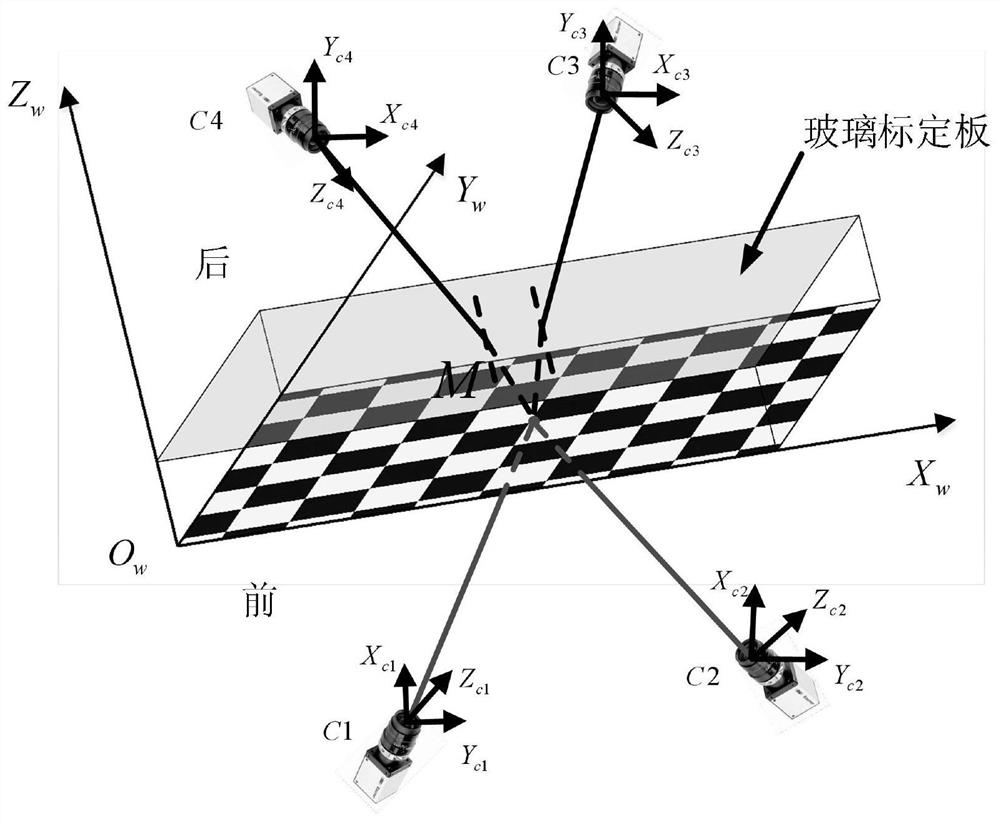

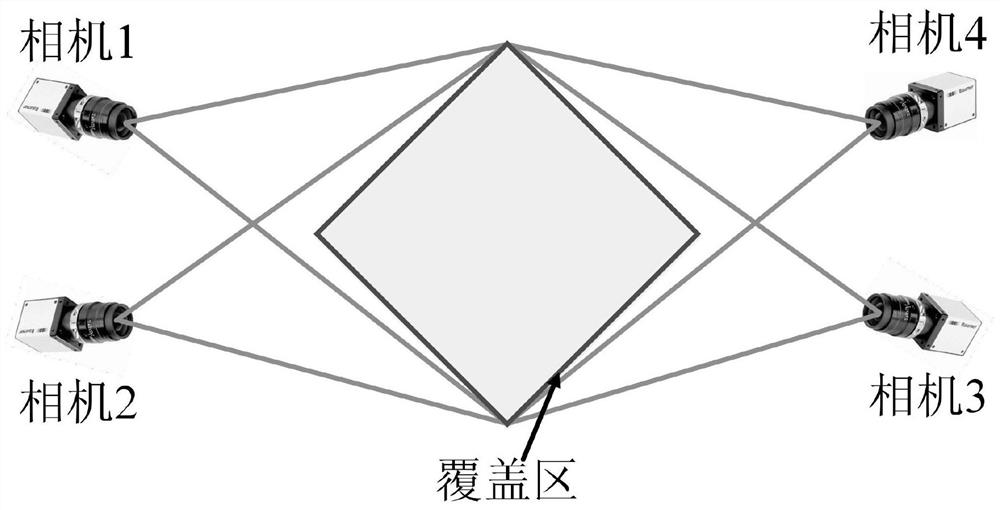

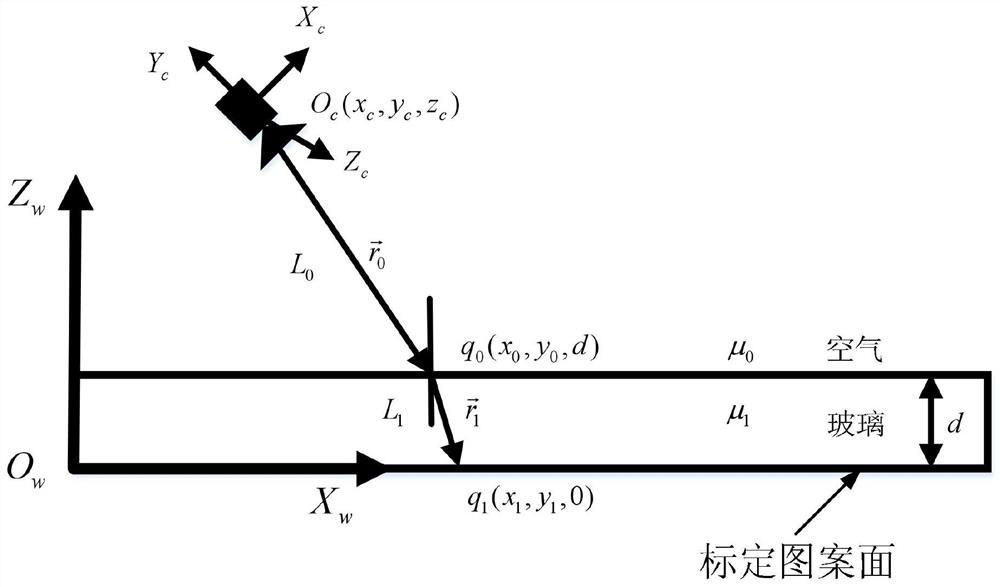

[0046] Such as figure 1Shown is a schematic diagram of multi-camera calibration based on a transparent glass calibration plate. Without loss of generality, this patent uses a 4-camera system to verify a multi-camera calibration method based on the minimum optical path principle and a transparent glass calibration plate proposed by the present invention. Such as figure 1 As shown, the multi-camera calibration system includes: a transparent glass calibration plate with a calibration pattern printed on only one side; 4 cameras with the same parameters, two cameras are distributed in front of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com