Textile equipment cleaning device

A technology for cleaning devices and textile equipment, applied in the direction of electrostatic cleaning, cleaning methods and utensils, cleaning methods using gas flow, etc., can solve problems such as difficult cleaning, and achieve cleanliness, high recycling efficiency, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

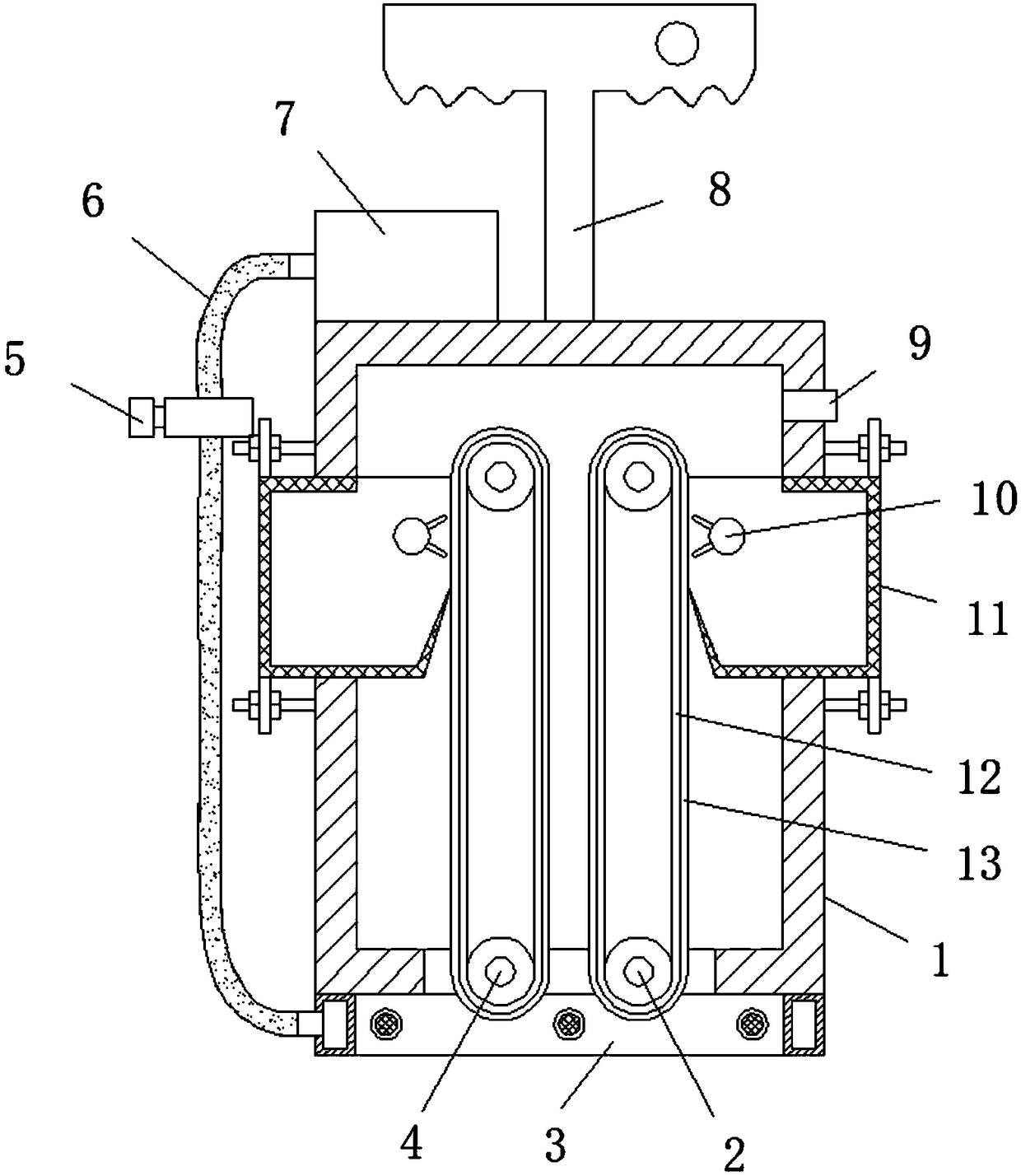

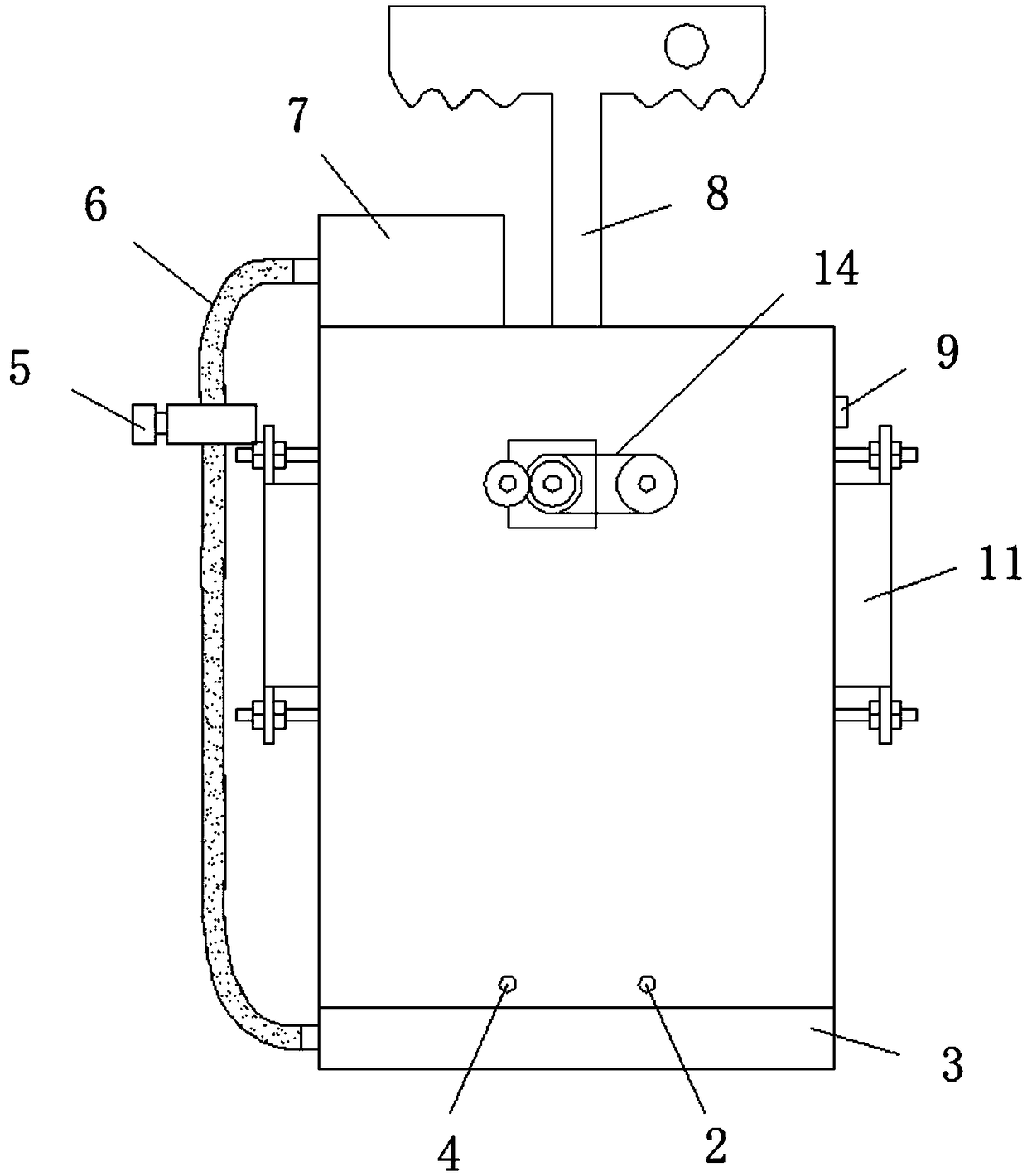

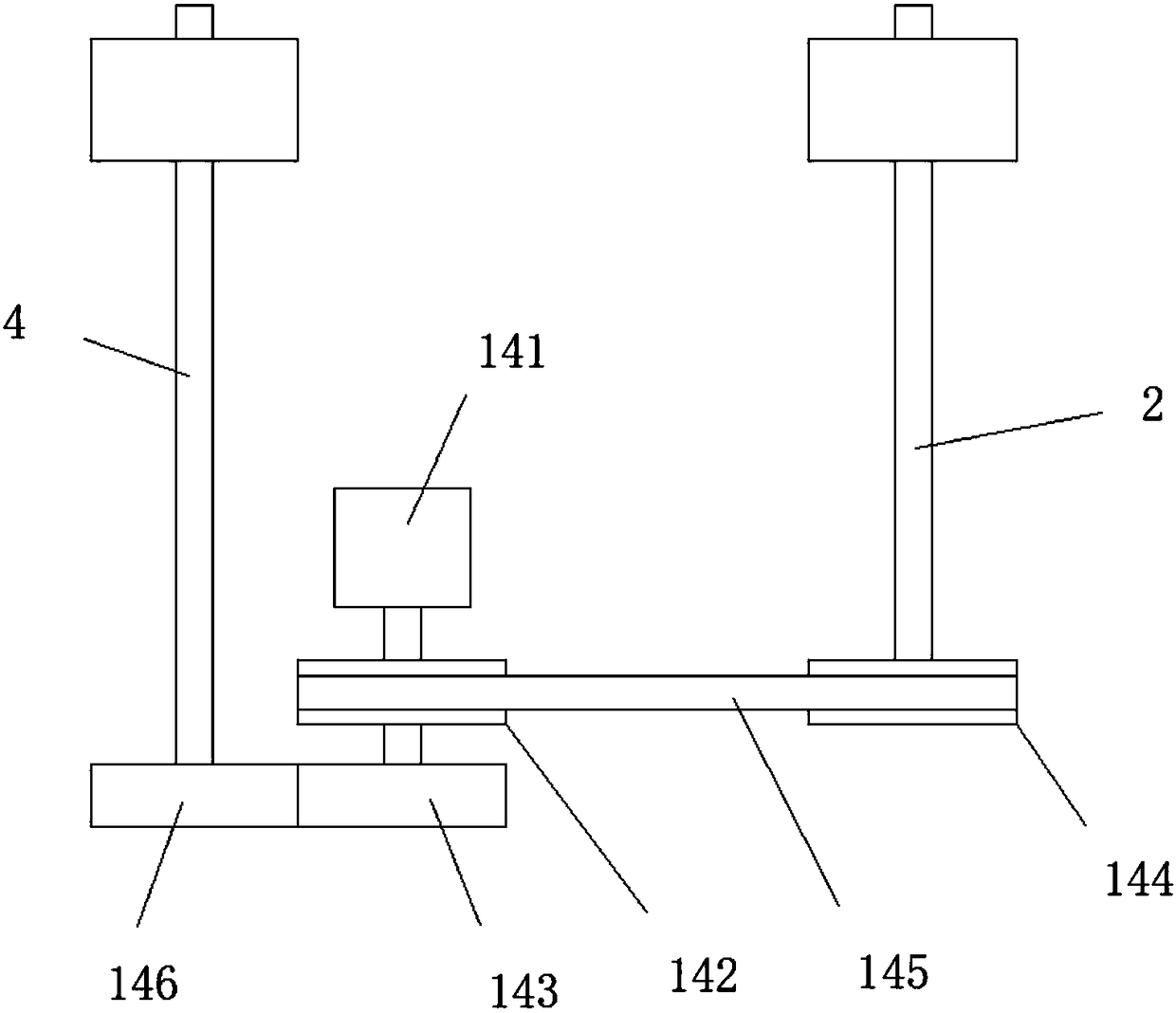

[0025] refer to figure 1 , 2 , 3, 4, 5, 6, a textile equipment cleaning device, comprising a housing 1, the housing 1 is a hollow cylinder, the bottom of the housing 1 is provided with a rectangular first through hole, the side of the housing 1 There are two sets of second through holes symmetrically arranged. The inside of the housing 1 and the first through hole at the bottom of the housing 1 are rotatably installed with a first rotating shaft 2 and a second rotating shaft 4, two first rotating shafts 2 and two Belt pulleys are installed on the second rotating shafts 4, belts 12 are connected between the two first rotating shafts 2 and between the two second rotating shafts 4, and electrostatic dust-absorbing cloths 13 are sewn on the outsides of the two sets of belts 12, A recovery device is installed in the second through hole, a driving device 14 is installed on the side of the housing 1, an exhaust pipe 9 is connected to the side of the housing 1, an air injection devic...

Embodiment 2

[0030] refer to figure 1 , 2 , 3, 5, 6, a textile equipment cleaning device, comprising a housing 1, the housing 1 is a hollow cylinder, the bottom of the housing 1 is provided with a rectangular first through hole, and the side of the housing 1 is provided with Two sets of symmetrically arranged second through holes, the inside of the housing 1 and the first through holes at the bottom of the housing 1 are rotatably installed with the first rotating shaft 2 and the second rotating shaft 4, two first rotating shafts 2 and two second rotating shafts Belt pulleys are installed on the two rotating shafts 4, and belts 12 are connected between the two first rotating shafts 2 and between the two second rotating shafts 4, and the outsides of the two groups of belts 12 are all sewn with electrostatic dust-absorbing cloths 13. A recovery device is installed in the through hole, a driving device 14 is installed on the side of the housing 1, an exhaust pipe 9 is connected to the side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com