Emulsified liquid vacuum filter spray device

A spraying device and emulsion technology, which is applied in the direction of cartridge filters, filtration separation, chemical instruments and methods, etc., can solve the problems of reducing the filtering effect of filter paper, easily broken and damaged filter paper, filter paper impact, etc., so as to reduce impact and stabilize the use , to ensure the effect of filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described in further detail now in conjunction with accompanying drawing.

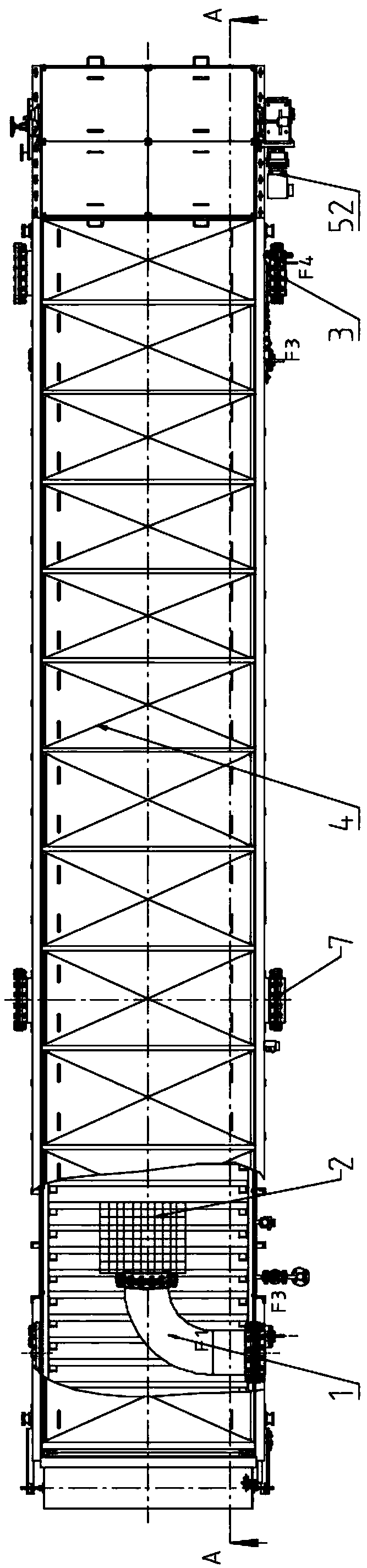

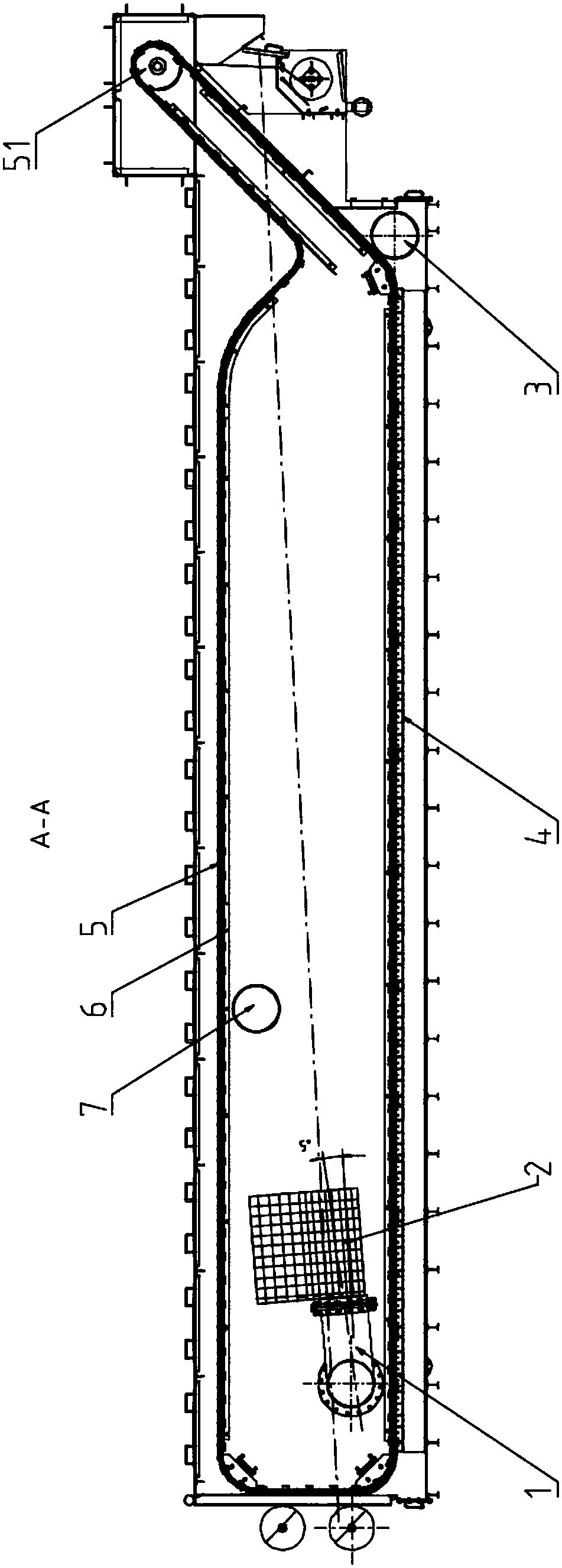

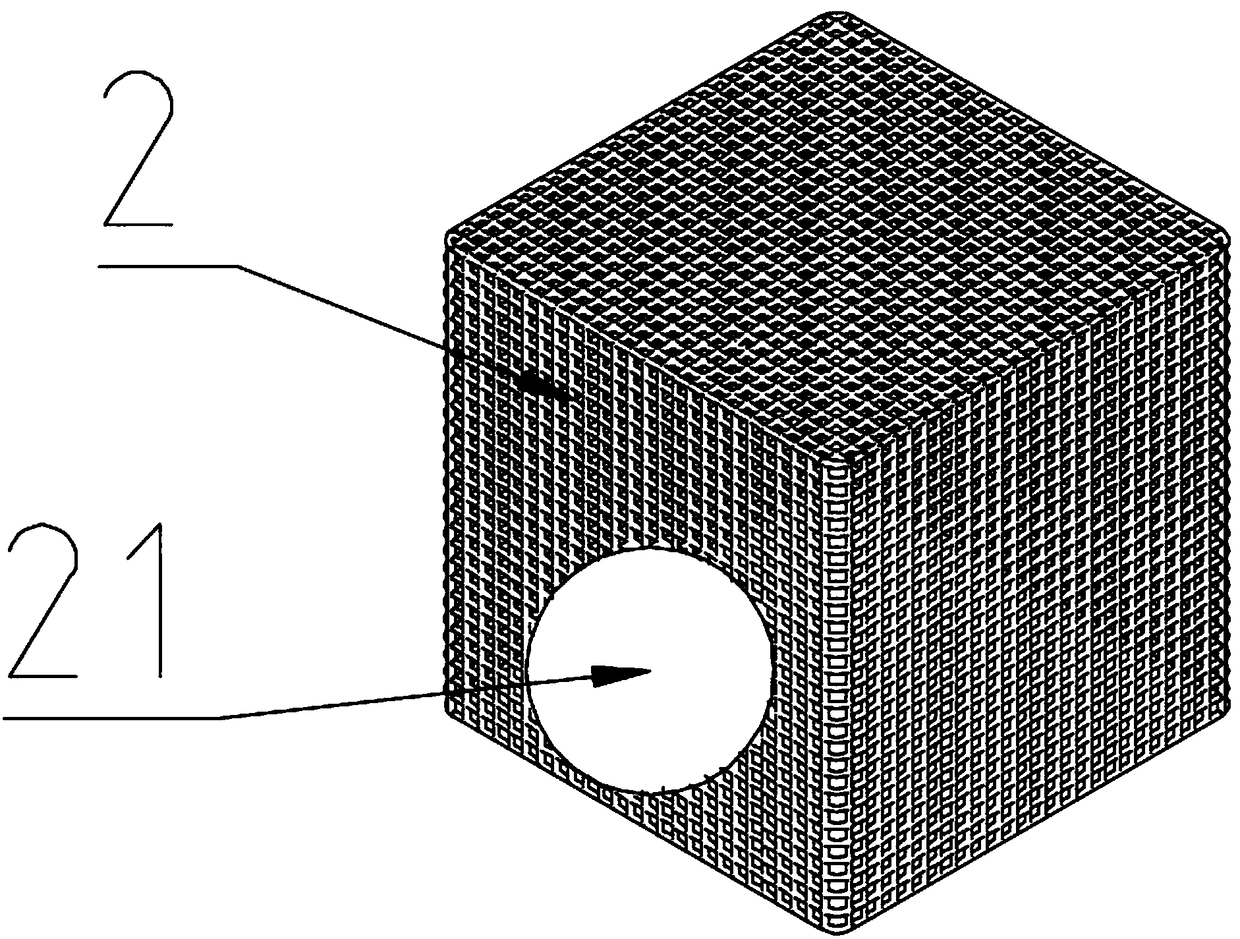

[0016] Such as Figure 1 to Figure 4 An emulsion vacuum filter injection device shown includes a filter box 4, an injection pipe 1, a drive motor 51, a return pipe 3, a crawler belt 5, and a filter paper 6. The filter box 4 is provided with a crawler belt 5, and the crawler belt 5 is assembled On the driving roller 51 and the tensioning device, the driving motor 52 drives the driving roller 51 to rotate, the inner side of the crawler belt 5 is provided with a filter paper 6, and one end of the filter box 4 is provided with a spray pipe 1, and the spray pipe 1 is inside the filter box 4 One end of is provided with injection device 2, and described injection device 2 is set as cube structure, side length 800mm, and wherein side and top surface are made of iron net, and injection device 2 bottom surface is set as non-iron net surface, is open state, and injection device 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com