Piercing device

A technology of perforating device and perforating shaft, which is used in transportation and packaging, thin material handling, instruments, etc., can solve problems such as difficult stopping, and achieve the effect of improving stopping accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Next, embodiments of the present invention will be described with reference to the drawings.

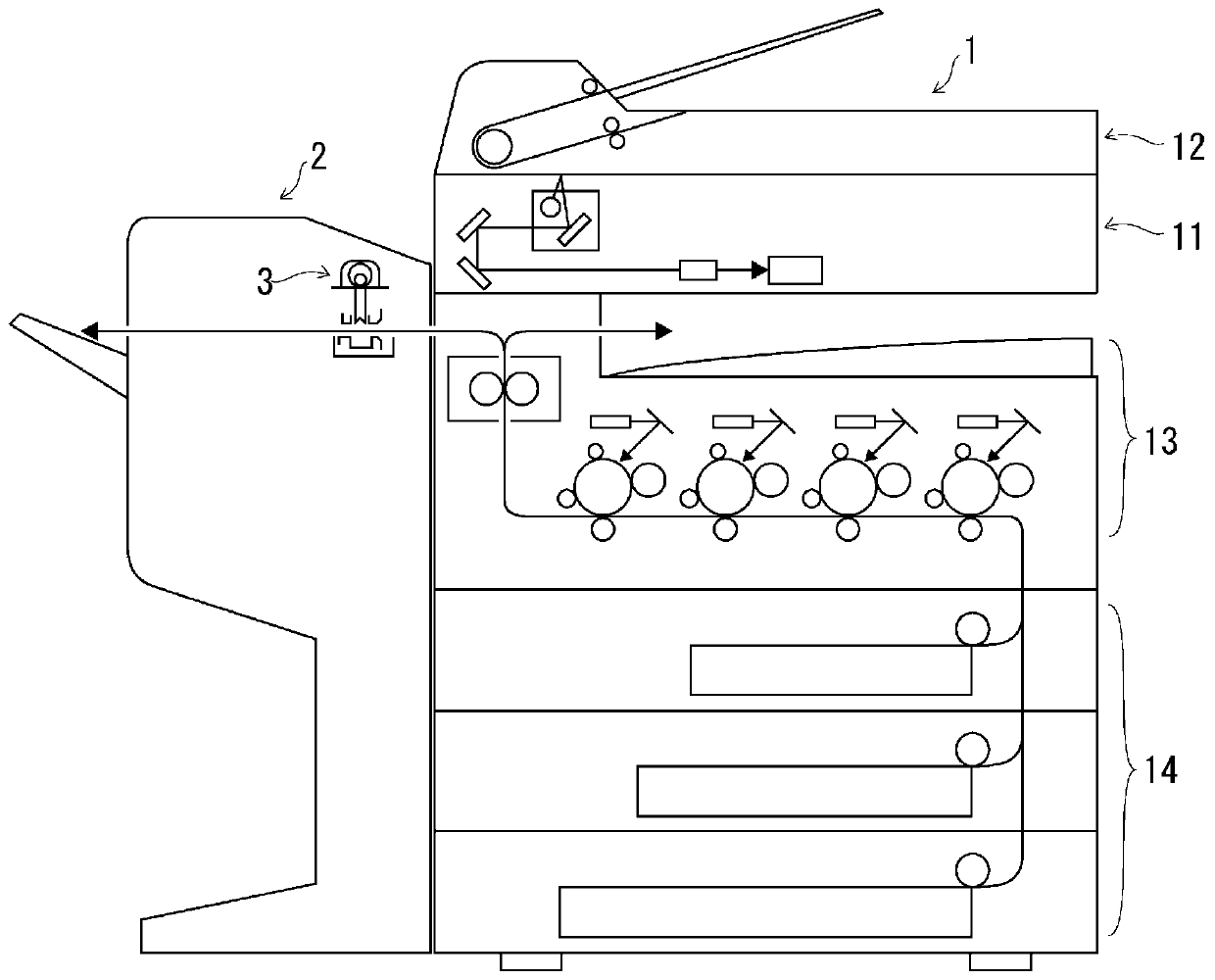

[0021] refer to figure 1 , The image forming system of this embodiment includes an image forming apparatus 1 that records and outputs a formed image on recording paper, and a post-processing that receives recording paper output from the image forming apparatus 1 and performs various post-processing on the received recording paper. device 2.

[0022] The image forming apparatus 1 is an electrophotographic copier or MFP (Multifunction Peripheral / Printer / Product, multifunctional printer / product / peripheral), etc., and includes a document reading unit 11, a document feeding unit 12, an image forming unit 13 and recording paper supply unit 14 . The image forming apparatus 1 executes image forming operations such as a copy job, a scan job, a facsimile transmission job, and a print job based on an operation accepted while logged in through user authentication.

[0023] Document rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com