Building steel structure connection device and connection structure

A technology of structural connection and construction steel, applied in the direction of building structure, construction, etc., can solve the problem of poor firmness of columns and beams, and achieve the effect of good firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

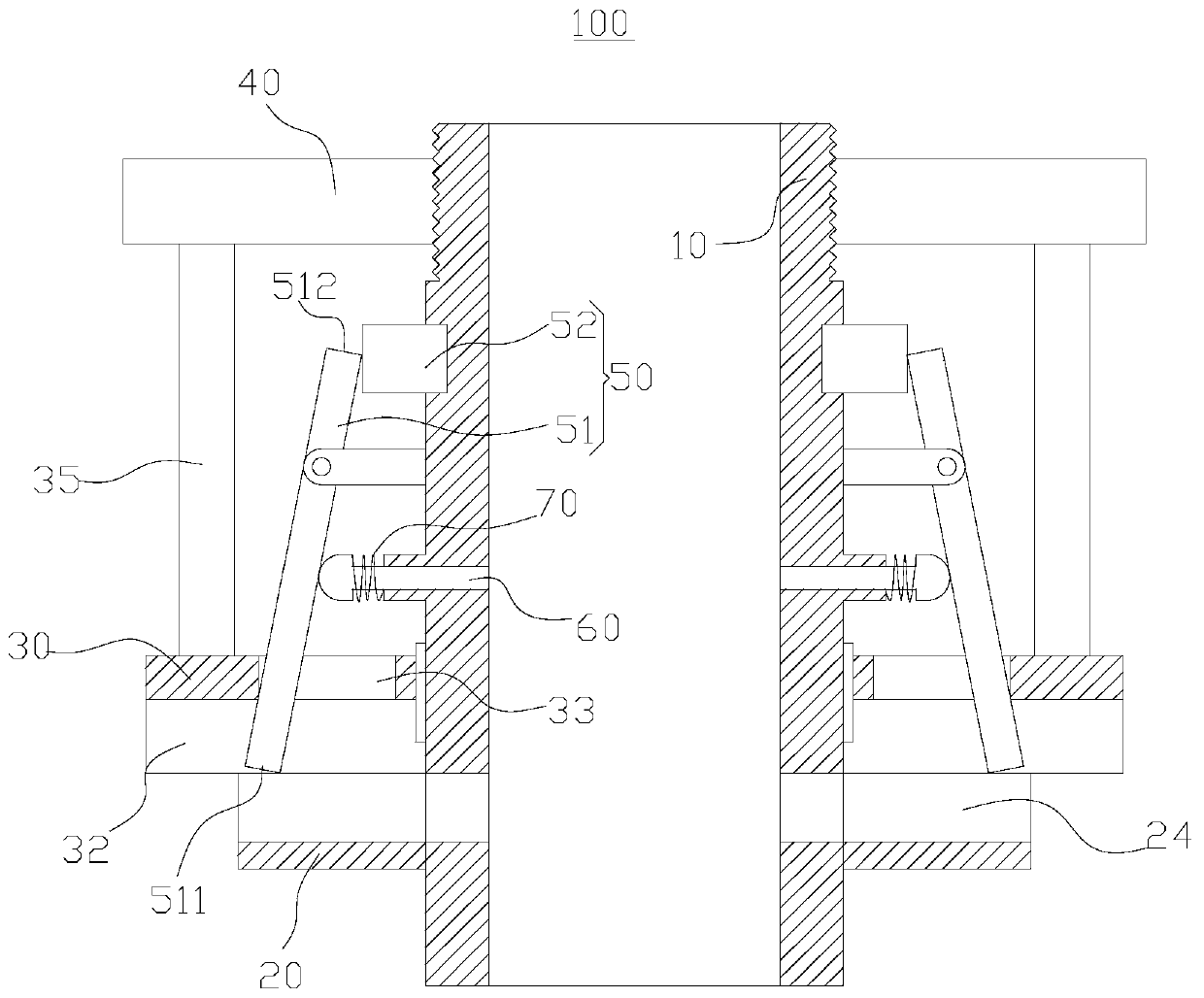

[0044] Such as figure 1 As shown, this embodiment provides a building steel structure connection device 100 for connecting a column 210 and a beam 220, which includes a center sleeve 10, a first clip body 20, a second clip body 30, a driving device 40, and a clamping device 50 and locking member 60.

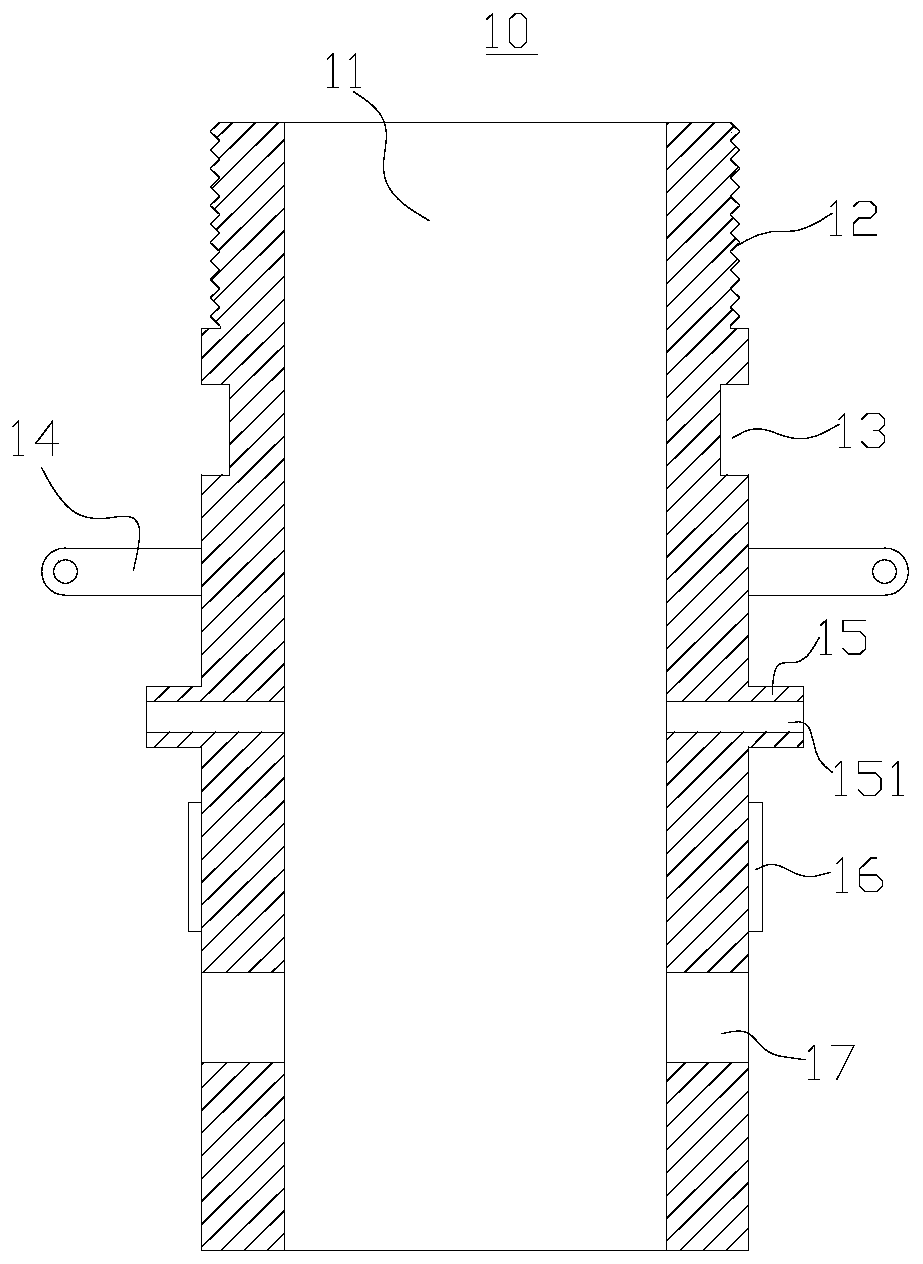

[0045] Among them, such as figure 2As shown, the central sleeve 10 is used to cooperate with the column 210. The central sleeve 10 is cylindrical and has a central hole 11. The shape of the central hole 11 is set according to the shape of the column 210, which can be circular, square, etc. The center sleeve 10 is sequentially provided with an external thread 12 , a sliding groove 13 , a hinge seat 14 , a protruding part 15 , a protruding line 16 and a socket 17 from top to bottom. The external thread 12 is located on the top of the center sleeve 10 . The chute 13 is opened along the tangential direction of the center sleeve 10 , and the chute 13 is a rectangular groove locate...

Embodiment 2

[0059] Such as Figure 8 As shown, the present embodiment provides a connection structure 200, including a column 210, a beam 220 and the building structure connection device in the above embodiment.

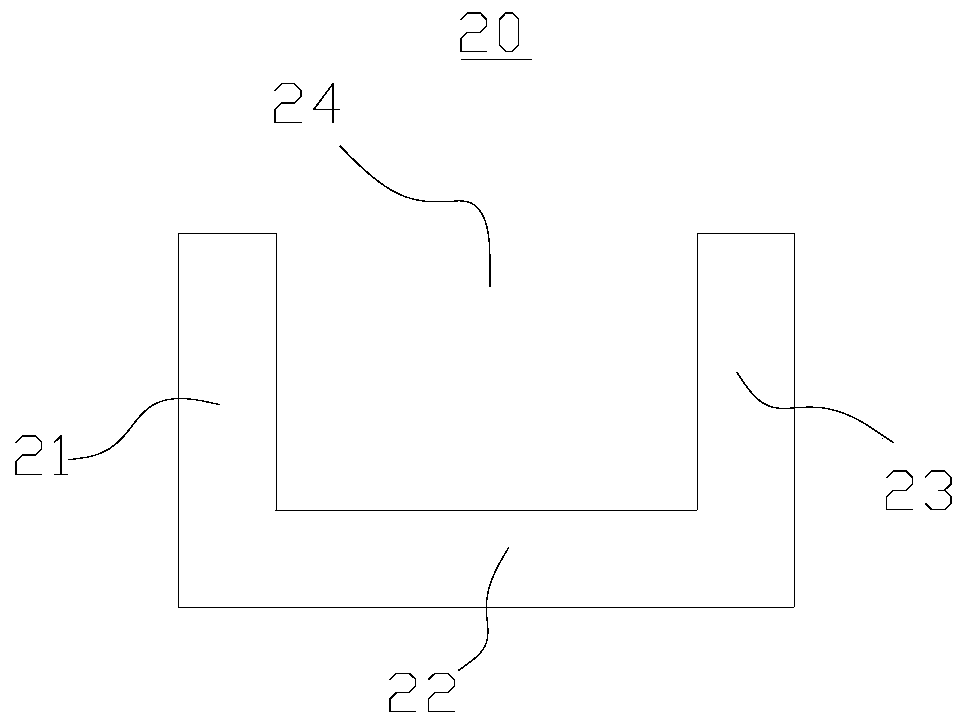

[0060] The center sleeve 10 is sleeved on the outside of the column 210 , and the locking member 60 locks the center sleeve 10 and the column 210 . In this embodiment, there are four beams 220, and the four beams 220 are respectively arranged in the receiving grooves 24 of the four first clamping bodies 20, and the first clamping part 21 and the second clamping part 23 are clamped to the width of the beam 220. On both sides in the direction, the base 22 and the actuator 51 are clamped on both sides of the beam 220 in the thickness direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com