Dynamic equipment monitoring method

A dynamic monitoring and equipment technology, which is applied in the direction of program control and control/regulation system in instruments, sequence/logic controllers, etc., can solve problems such as equipment protective shutdown, equipment damage, accidents, etc., and achieve the effect of early warning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

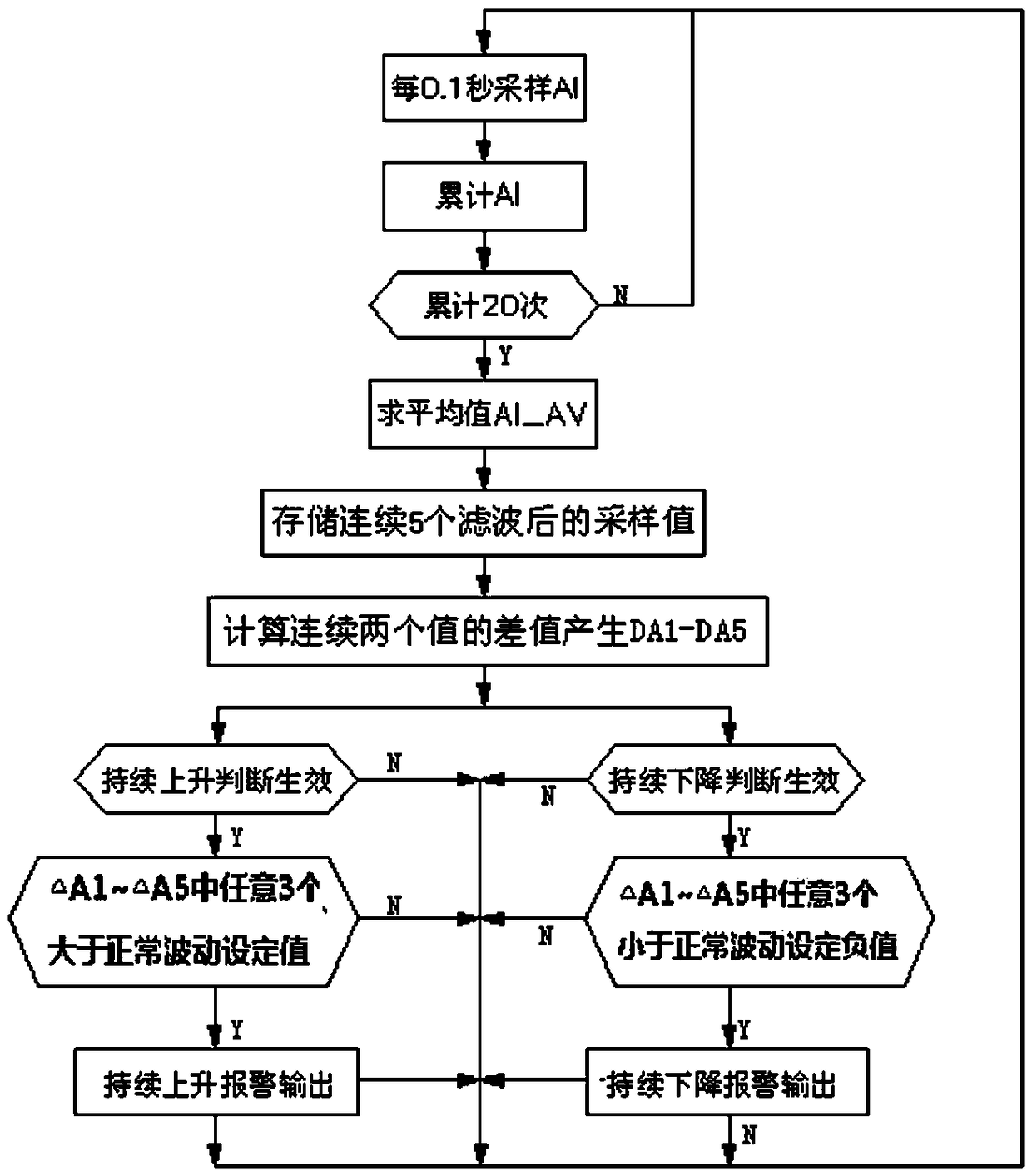

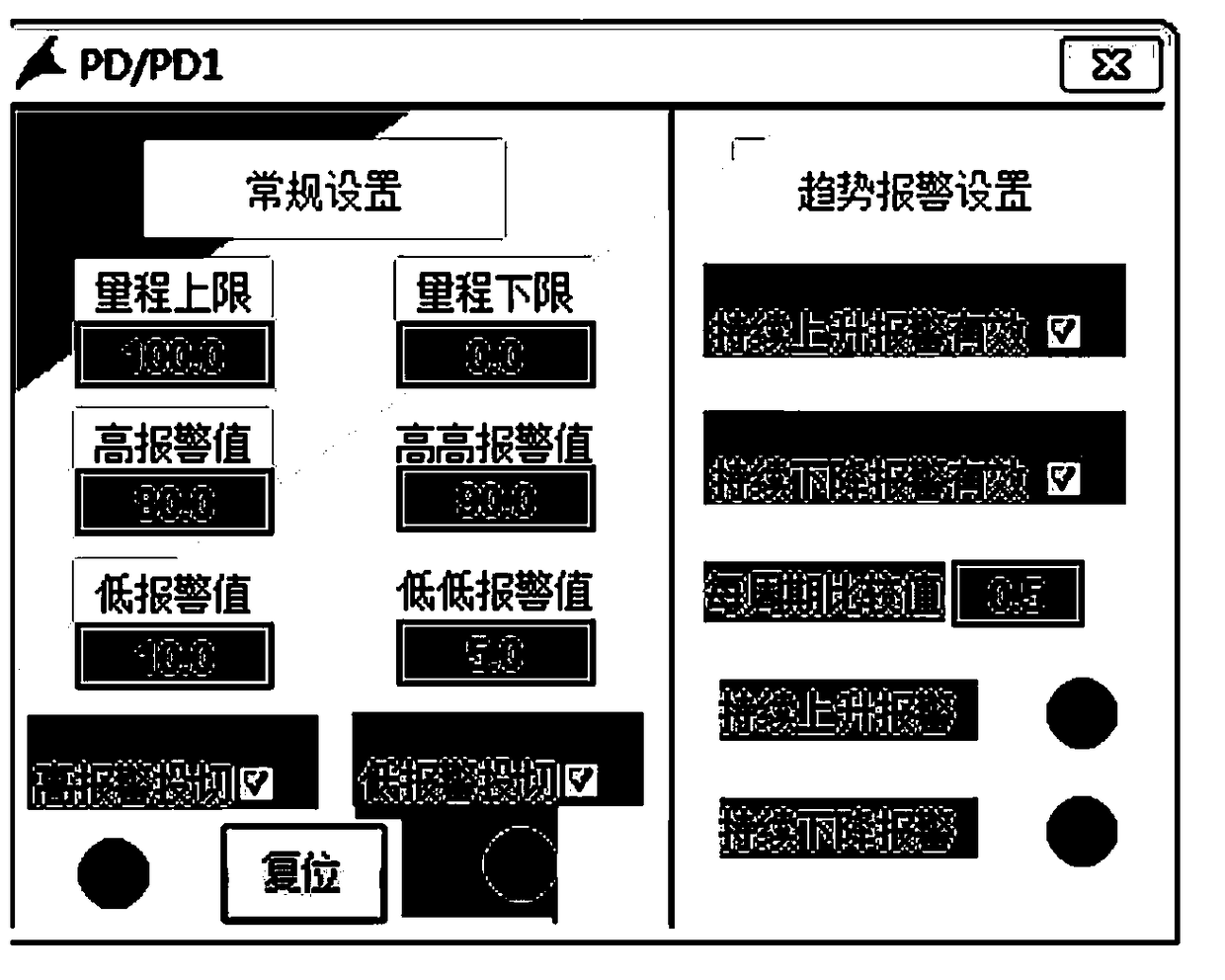

Method used

Image

Examples

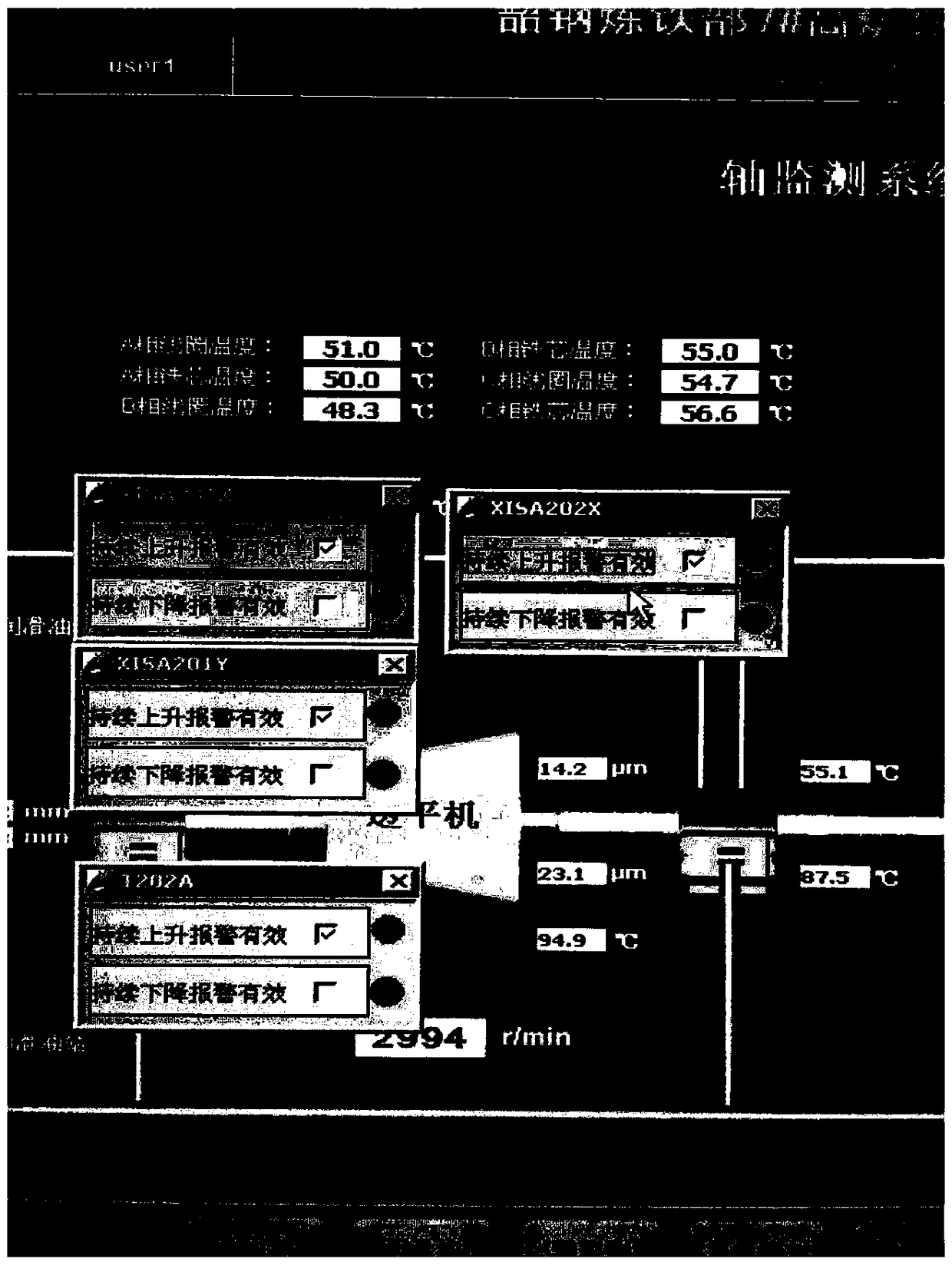

Embodiment 1

[0016] see image 3 , taking the operation of a certain large-scale rotating equipment as an example: when a certain equipment is running, the general vibration value is below 40um, the high alarm value is 130um, and the high-high protection shutdown value is 160um. The trend alarm is used. As long as the program judges that multiple consecutive sampling values continue increase, an alarm will be issued for the deterioration of the equipment status to remind the operator to take timely intervention measures. XISA201X, XISA201Y, and XISA202X in the figure below show the shaft vibration value alarm screen of the blast furnace residual pressure power generation (TRT) unit. This screen will not be displayed on the main control screen during normal operation. When the alarm condition is reached, the screen will pop up automatically. Alert the operator. T202A in the figure is the temperature alarm screen of a certain bearing in the shaft system. Similarly, the screen will not be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com