A Molten Salt Heap Upper Chamber

A molten salt reactor and chamber technology, applied in the field of upper chamber of molten salt reactor, can solve the problems of difficult radioactive management, inability to effectively remove tritium, molten salt leakage, etc., to improve separation and collection efficiency, avoid irradiation and corrosion Problem, effect of wide cross-sectional area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

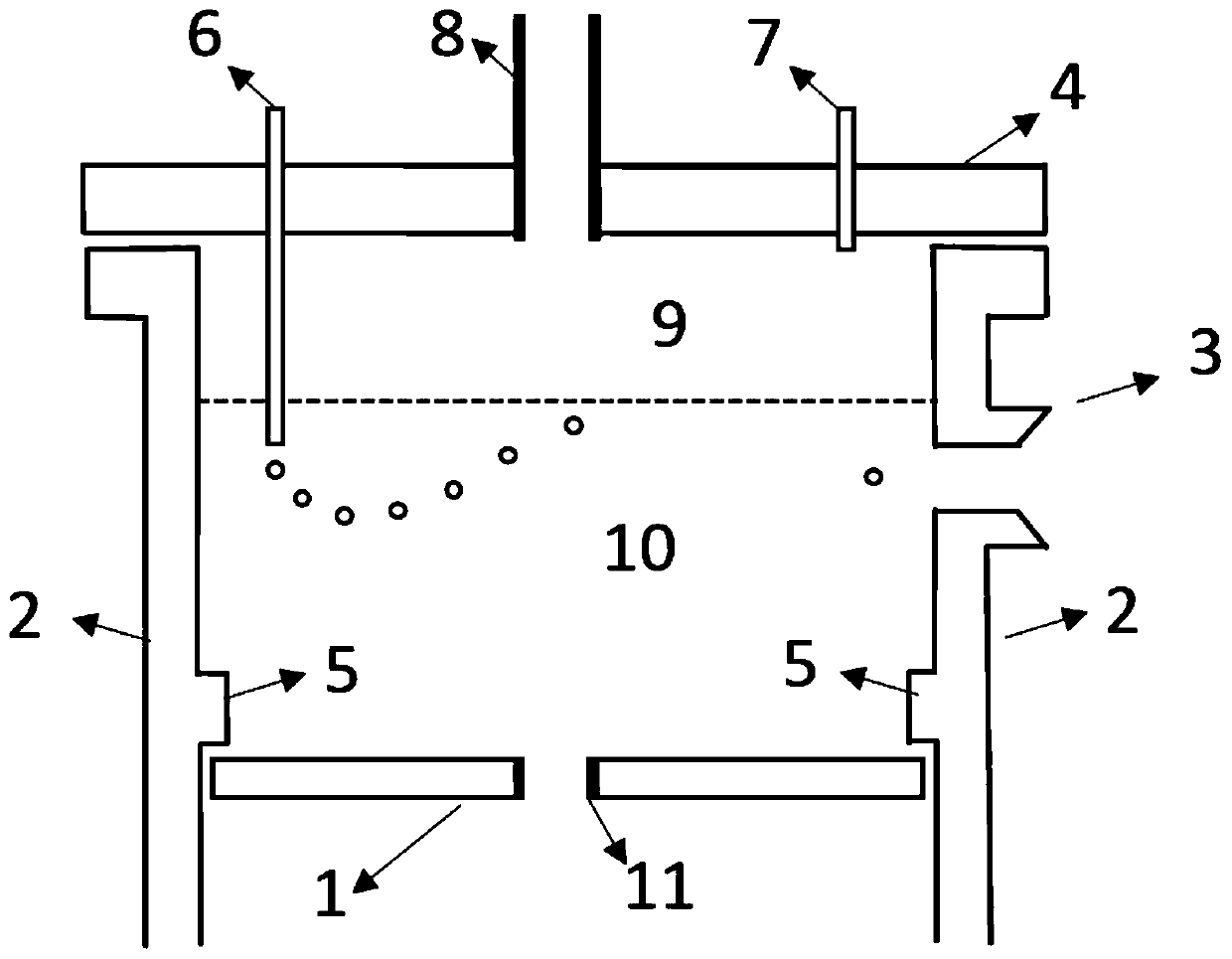

[0056] figure 1 It is a structural schematic diagram of the upper chamber of a molten salt reactor, which includes a support plate 1 arranged in the core vessel 2 as the bottom of the upper chamber of the molten salt reactor, and a cover plate 4 arranged on the top of the core vessel 2;

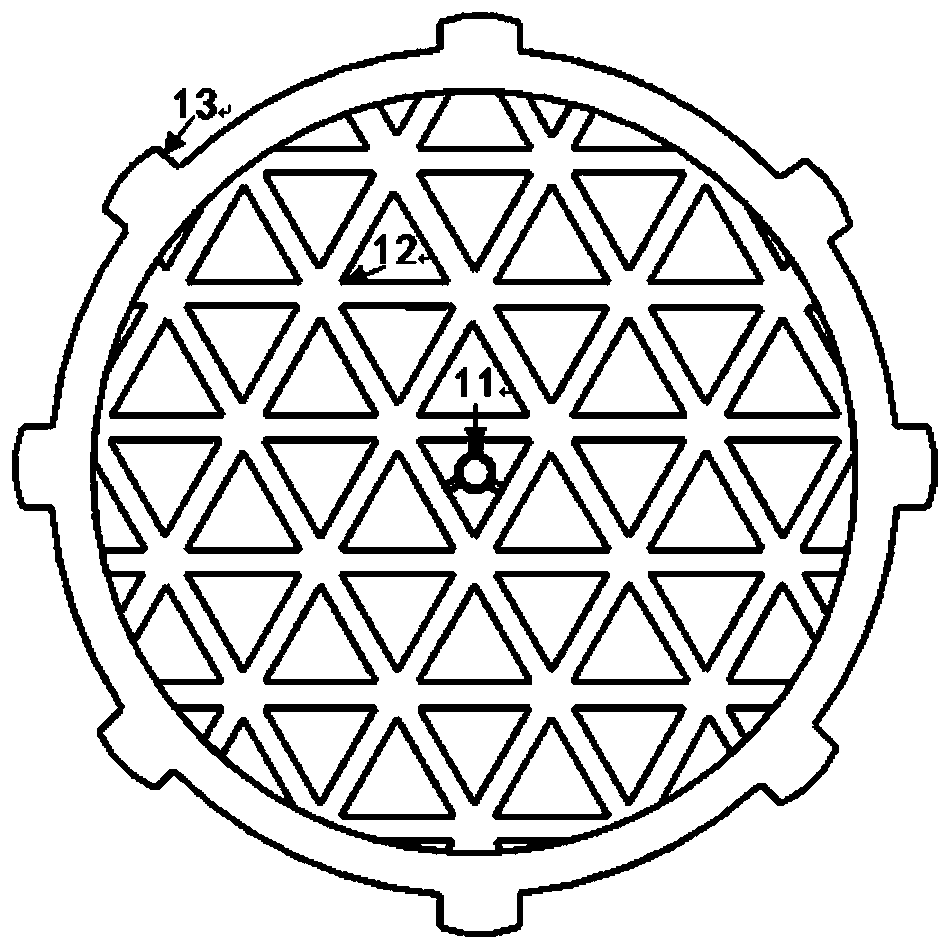

[0057] Wherein, the support plate 1 is provided with several control rod guide ports 11;

[0058] Wherein, the core vessel 2 includes a side nozzle 3, the side nozzle 3 is located above the support plate 1, and the side nozzle 3 is located below the preset molten salt liquid level;

[0059] Among them, the cover plate 4 is pierced with an inert gas inlet pipe 6 and an inert gas outlet pipe 7; the bottom end of the inert gas inlet pipe 6 is located below the preset molten salt liquid level, and is higher than the support plate 1; the inert gas outlet pipe 7 The bottom end is located above the preset molten salt level.

[0060] In this embodiment, the material of the support plate 1 is a nic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com