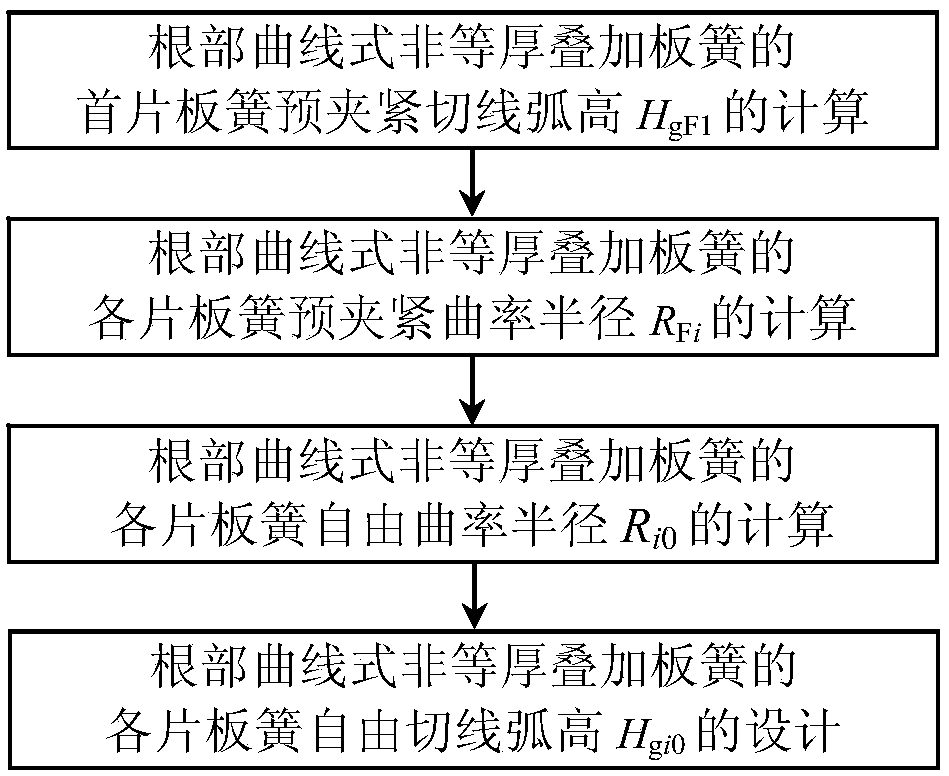

Design method for free tangent line arc heights of root curvilinear-style unequal thickness stacked plate spring

A curvilinear, non-equal thickness technology, applied in computer-aided design, leaf spring, calculation and other directions, can solve the problems of not giving accurate and reliable non-equal thickness superimposed leaf springs, unable to meet the modern CAD design of suspension leaf springs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

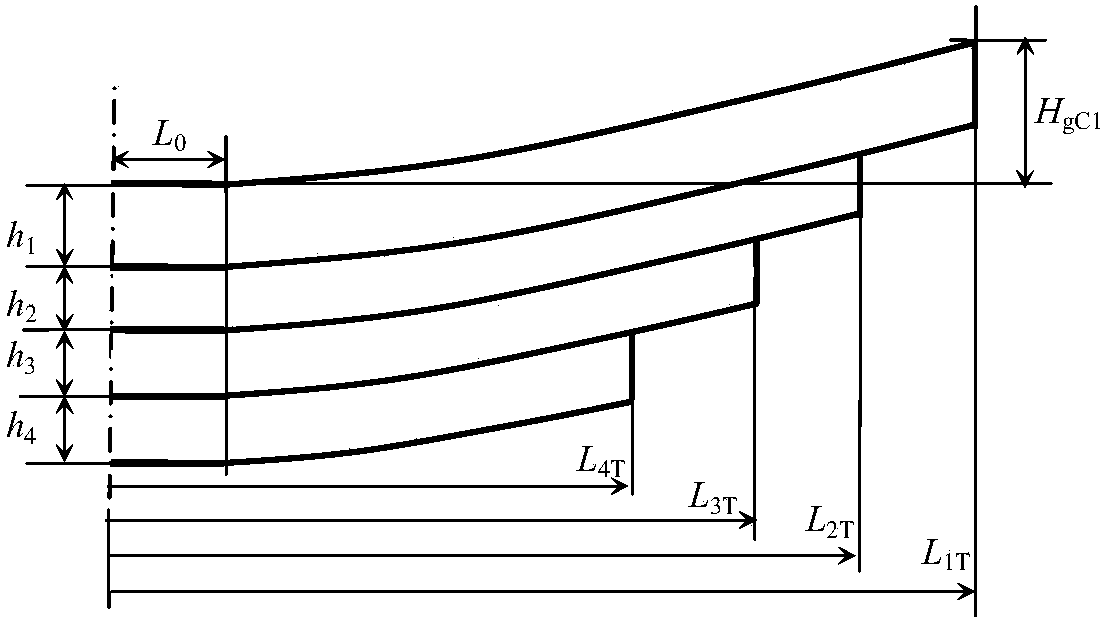

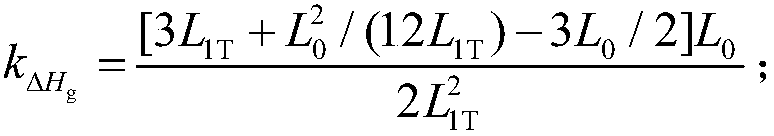

[0032] Embodiment 1: the width b=60mm of a curved non-equal-thickness stacked leaf spring at the root, the modulus of elasticity E=200GPa; the number of leaf springs n=5, and the thickness of each leaf spring is h 1 = 9mm, h 2 = 8mm, h 3 = 8mm, h 4 = 10mm, h 5 =10mm; Half of the effective length of each leaf spring is L 1T =575mm,L 2T =525mm,L 3T =475mm, L 4T =425mm,L 5T = 375mm. Half of the saddle bolt clamping distance L 0 =50mm, the design requirement value of the pre-clamping stress of each leaf spring is σ 1 =-44.6MPa, σ 2 =-28.2MPa, σ 3 = 0MPa, σ 4 =18MPa, σ 5 =36.13MPa, the design requirement value H of the arc height of the clamping tangent line of the first leaf spring assembly after the saddle bolt assembly is clamped gC1= 100mm. According to the number of leaf springs, modulus of elasticity, the structural parameters of each leaf spring, the required value of the pre-clamping stress design of each leaf spring, and the arc height of the clamping tangen...

Embodiment 2

[0066] Embodiment two: the width b=60mm of the non-equal-thickness stacked leaf spring of a certain root curve type, the modulus of elasticity E=200GPa; the number of leaf springs n=4, and the thickness of each leaf spring is h 1 = 10mm, h 2 = 9mm, h 3 = 9mm, h 4 =9mm; Half of the effective length of each leaf spring is L 1T =575mm, L 2T =525mm, L 3T =475mm, L 4T =425mm. Half of the saddle bolt clamping distance L 0 =55mm, the design requirement value of the pre-clamping stress of each leaf spring is σ 1 =-67.73MPa, σ 2 =-27.87Mpa, σ 3 =27.87Mpa, σ 4 =83.62MPa, the design requirement value of the arc height of the first leaf spring assembly and clamping tangent line after saddle bolt assembly and clamping is H gC1 = 100mm. According to the number of leaf springs, elastic modulus, the structural parameters of each leaf spring, the design requirements of the pre-clamping stress of each leaf spring, and the assembly clamping tangent arc of the first leaf spring after ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com