STO (safe torque off) control circuit and drive system

A technology of safe torque off and control circuit, applied in the field of transmission, to achieve the effect of increasing reliability, improving development efficiency and improving safety level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

no. 1 example

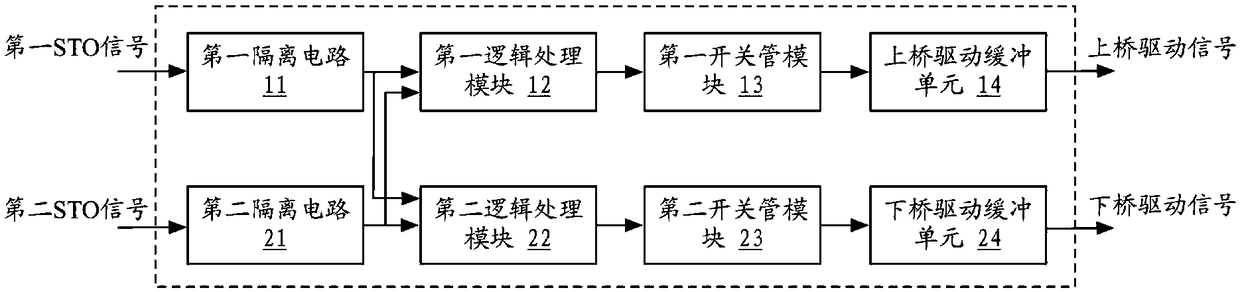

[0028] Such as figure 1 As shown, the first embodiment of the present invention provides a safe torque off control circuit, the safe torque off control circuit includes: a first isolation circuit 11, a first logic processing module 12, a first switching tube module 13 , the upper bridge drive buffer unit 14, the second isolation circuit 21, the second logic processing module 22, the second switching tube module 23 and the lower bridge drive buffer unit 24;

[0029] The first isolation circuit 11 is used to isolate the input first STO signal to obtain the first STO signal after isolation processing; the second isolation circuit 21 is used to isolate the input second STO signal processing to obtain the isolated second STO signal; the isolated first STO signal and the second STO signal are mutually inverse logic signals.

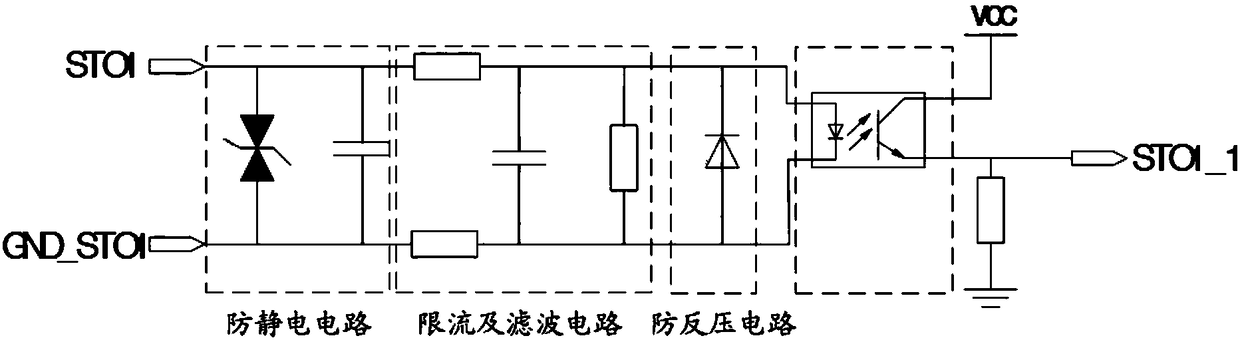

[0030] In this embodiment, the first isolation circuit 11 and the second isolation circuit 21 respectively include a current limiting and filtering circuit, a...

no. 2 example

[0061] The second embodiment of the present invention provides a transmission system, which includes the safe torque off control circuit described in the first embodiment. For the safe torque off control circuit, reference may be made to the above content, and details are not described here.

[0062] In order to better understand this embodiment, the following combination Figure 9 Explain the working process of the transmission system:

[0063] Such as Figure 9 As shown, the transmission system includes a safe torque off control circuit, a controller, an upper bridge drive optocoupler, a lower bridge drive optocoupler, an inverter-side power switch tube, and a motor.

[0064] The safe torque off control circuit controls the PWM drive signal from the controller by controlling the power supply VCC or the enable signal EN of the upper bridge drive buffer unit and the lower bridge drive buffer unit, and then controls the output of the upper bridge / lower bridge drive signal . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com