Braking system of high-speed rail EMU

A technology for braking systems and EMUs, applied in electric braking systems, brakes, regenerative braking, etc., can solve problems such as large motor braking torque fluctuations and difficult phase commutation of inverter feedback devices, and achieve optimal braking Control, realize electric energy recycling, increase comfort effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

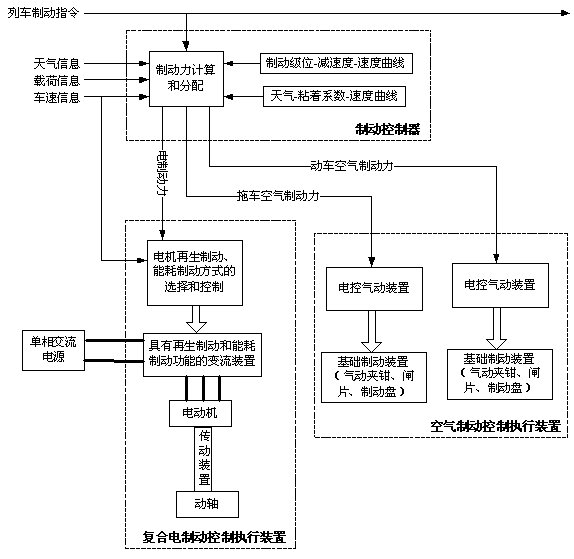

[0026] A high-speed rail EMU brake system includes a brake controller, a composite electric brake control execution device and an air brake control execution device, such as figure 1 .

[0027] The brake controller is installed in each motor car, and receives the brake level command, weather information, train load information and speed information from the driver, and calculates and distributes the braking force; specifically: according to the pre-stored deceleration- The speed curve and the adhesion coefficient-speed curve are determined by experiments, calculate the required braking force and maximum adhesion force, and ensure that the calculated braking force is less than the maximum adhesion force. The electric braking force is allocated according to the principle of electric braking priority. When the braking force is insufficient, the remaining calculated braking force is allocated to the air brake, and the air braking force is allocated to the braking device of the trailer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com