Push-assisting and pull-assisting apparatus of electronic equipment machine case

A technology of electronic equipment and chassis, which is applied in the direction of coupling devices, components of connecting devices, circuits, etc., can solve cumbersome problems, improve reliability, reduce operation difficulty, and avoid over-mating or under-mating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the drawings and embodiments:

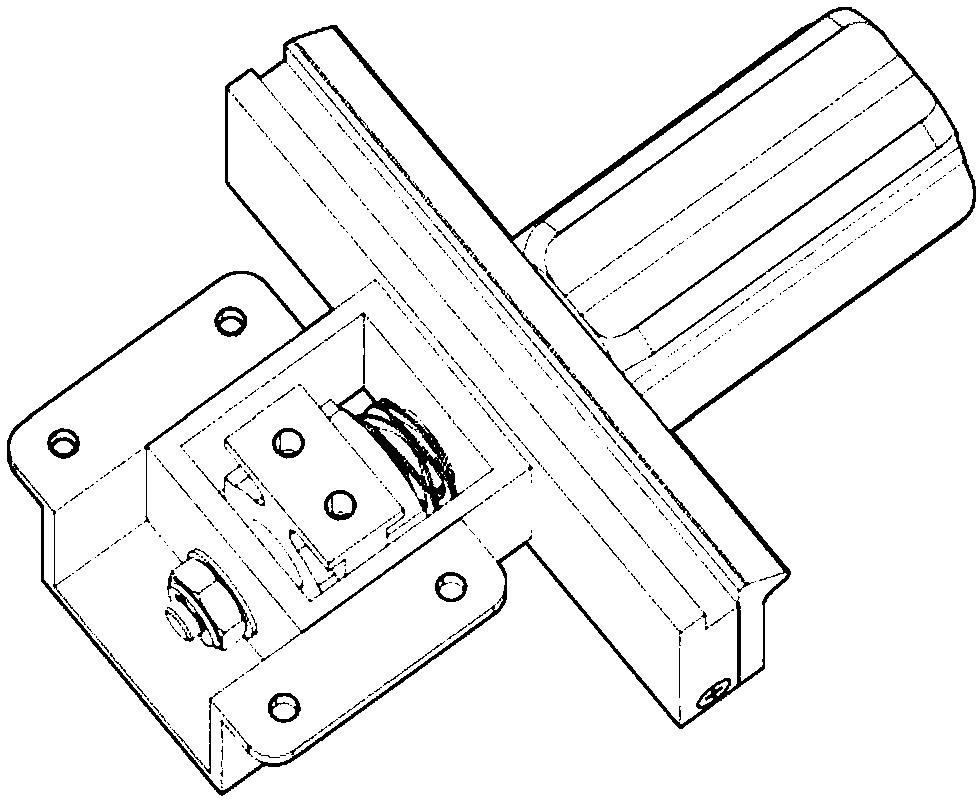

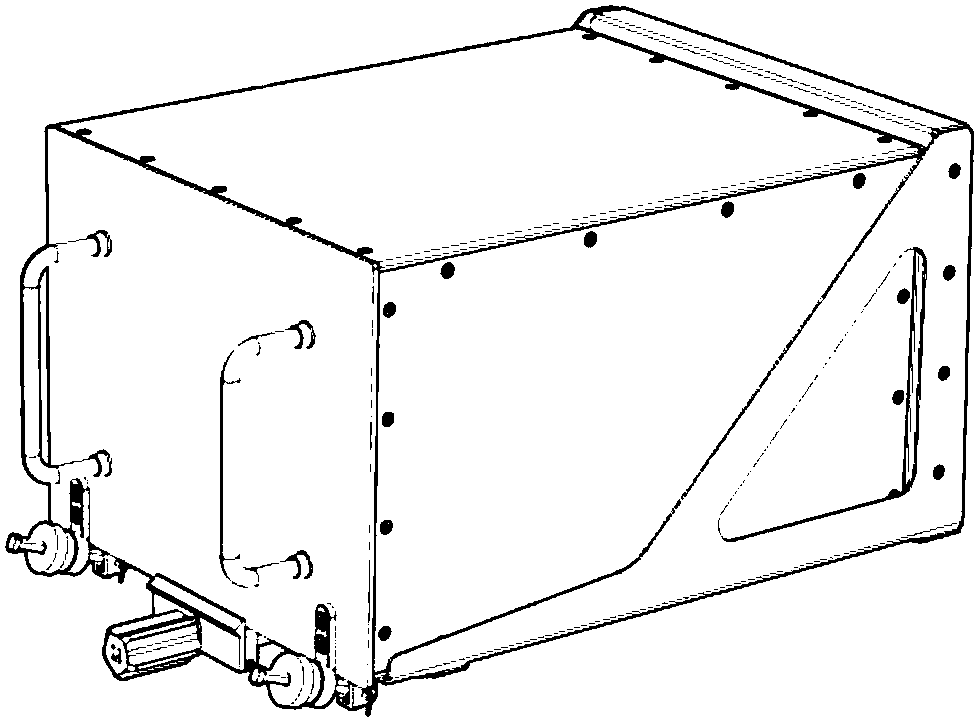

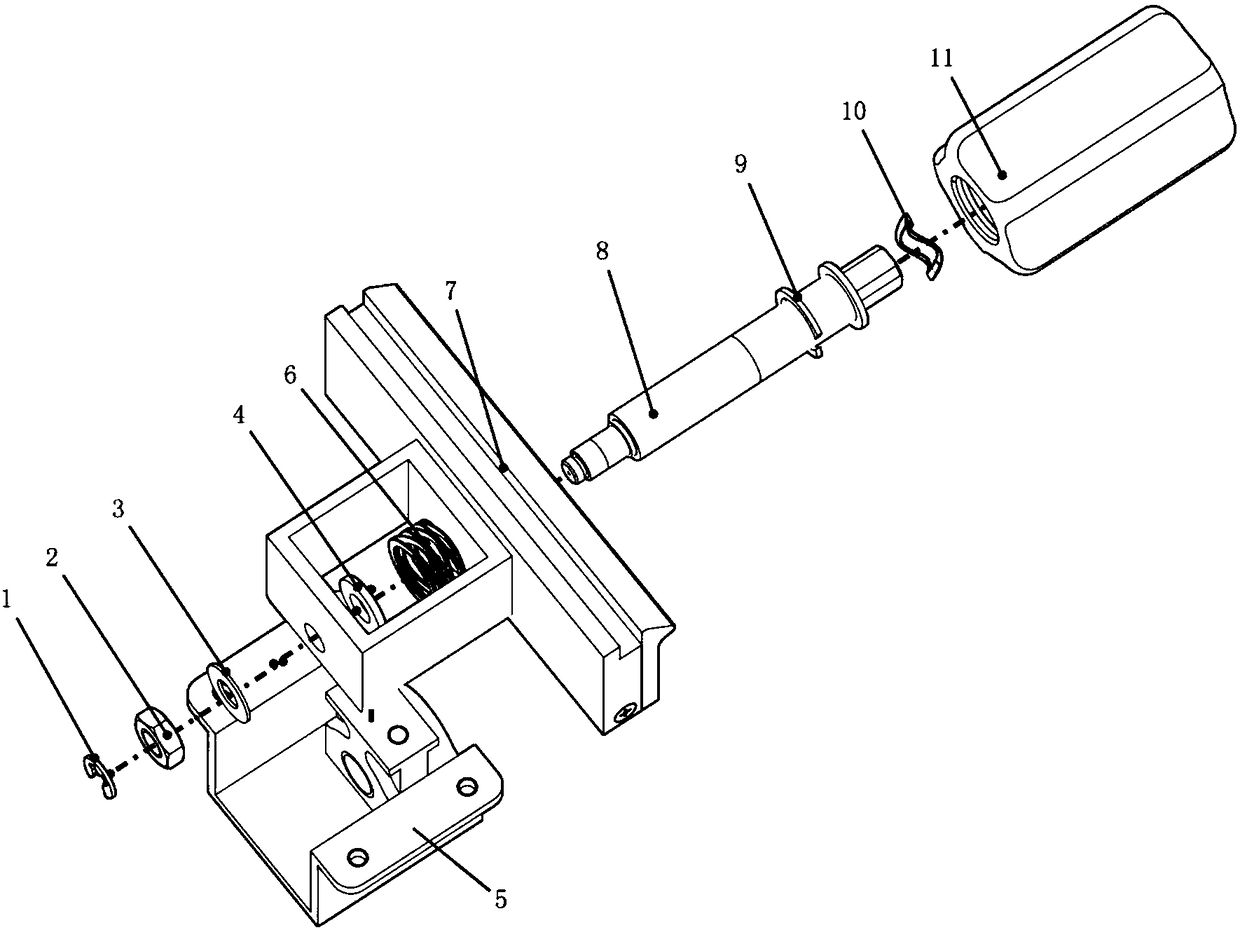

[0023] A device for assisting and pulling out electronic equipment chassis, the device includes a mounting base 5, a transmission shaft 8, an inner sliding block 12, and an outer sliding block 14.

[0024] The mounting base 5 is a structure with a groove, a boss is provided in the groove, and a threaded through hole parallel to the groove is provided on the boss;

[0025] The drive shaft 8 is a shaft with an external thread that matches the internal thread of the groove threaded through hole;

[0026] The inner sliding block 12 includes a frame structure. On the side wall of the frame structure, there is a through hole corresponding to the position of the threaded through hole of the boss of the mounting base 5; the outside of the frame structure can be embedded in the mounting base 5 In the groove, the boss of the mounting base 5 can extend outward from the frame structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com