Full-automatic in-mold implanting machine and application method

An in-mold implantation, fully automatic technology, applied in the coating and other directions, can solve the problems of nut dislocation, poor applicability and high height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

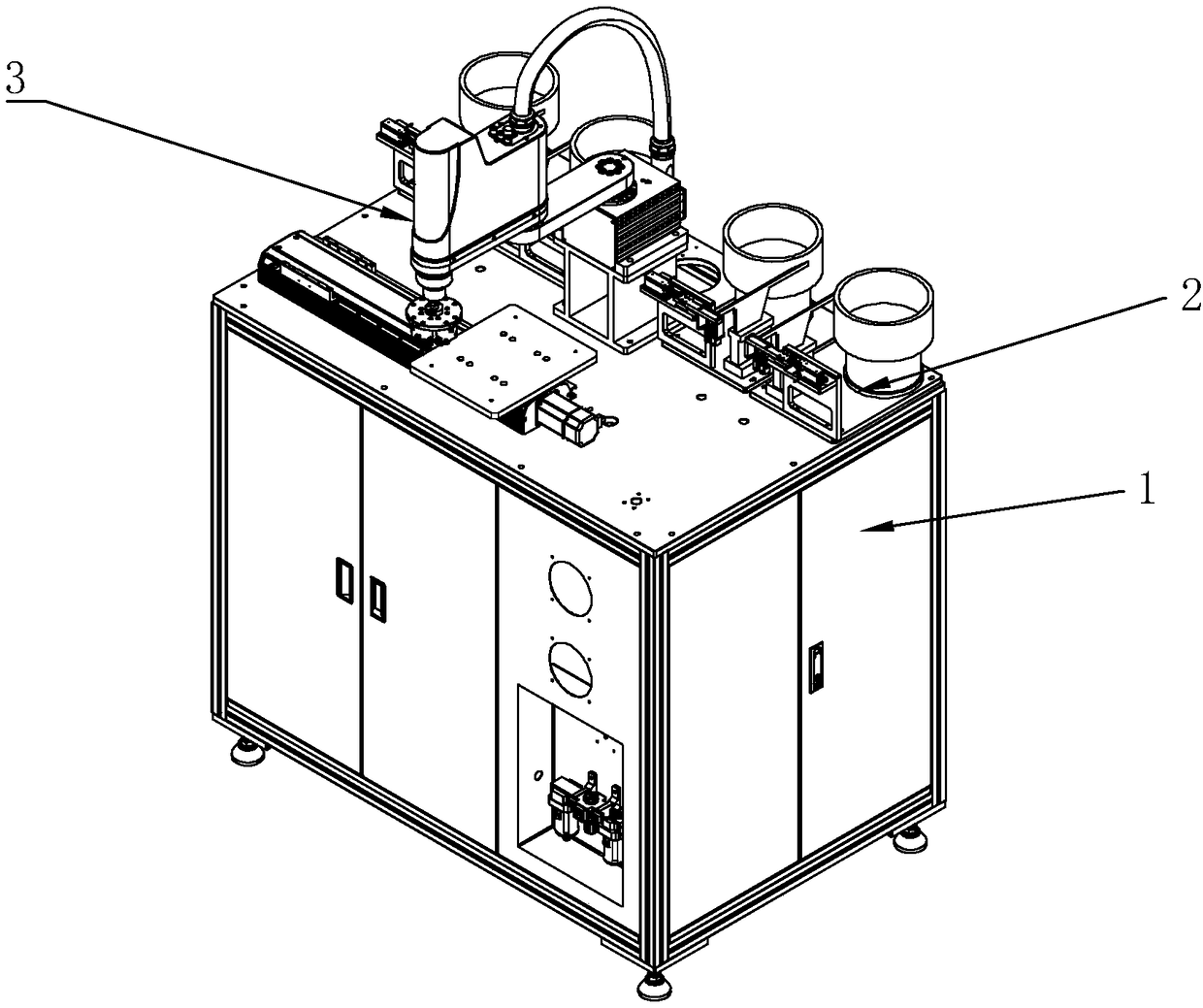

[0041] refer to Figure 1 to Figure 7 The embodiment of a fully automatic in-mold implanter of the present invention will be further described.

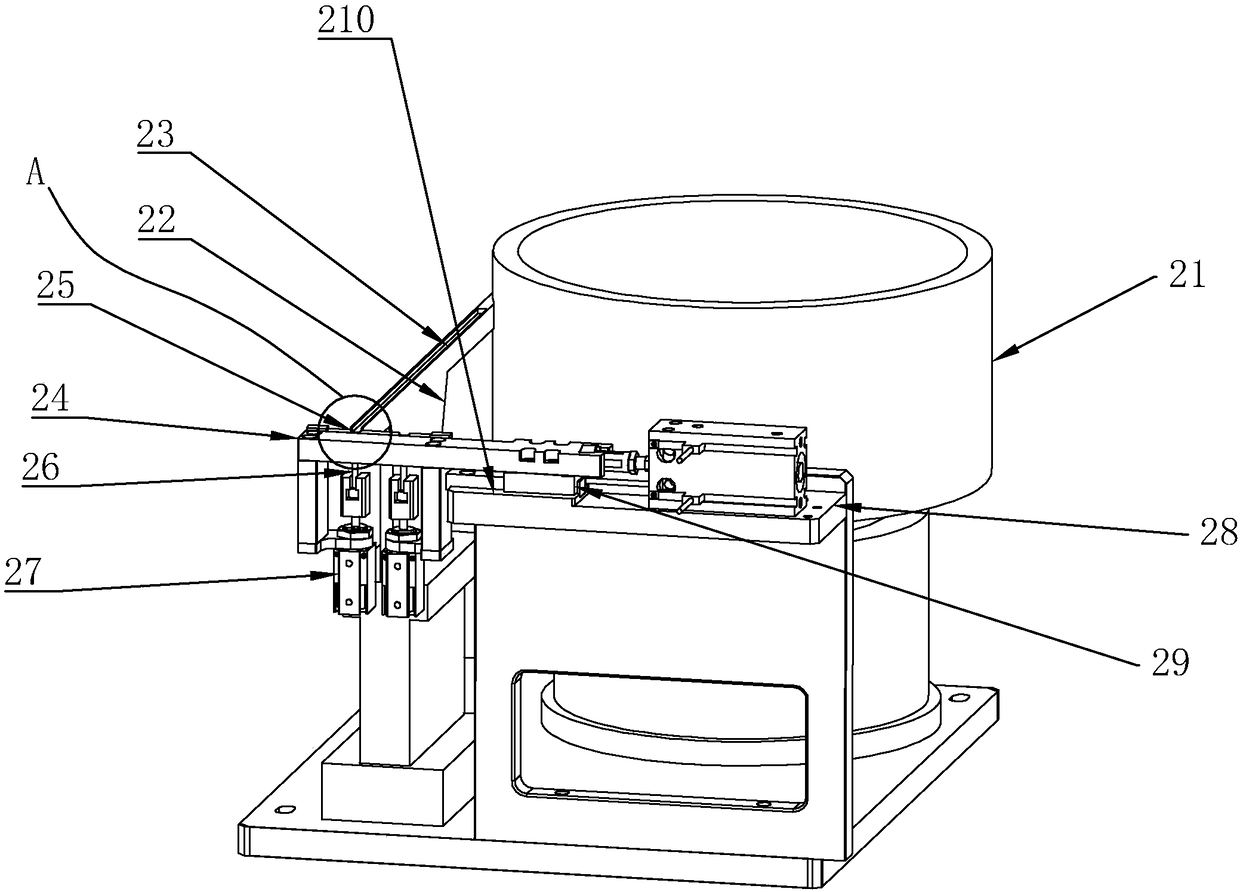

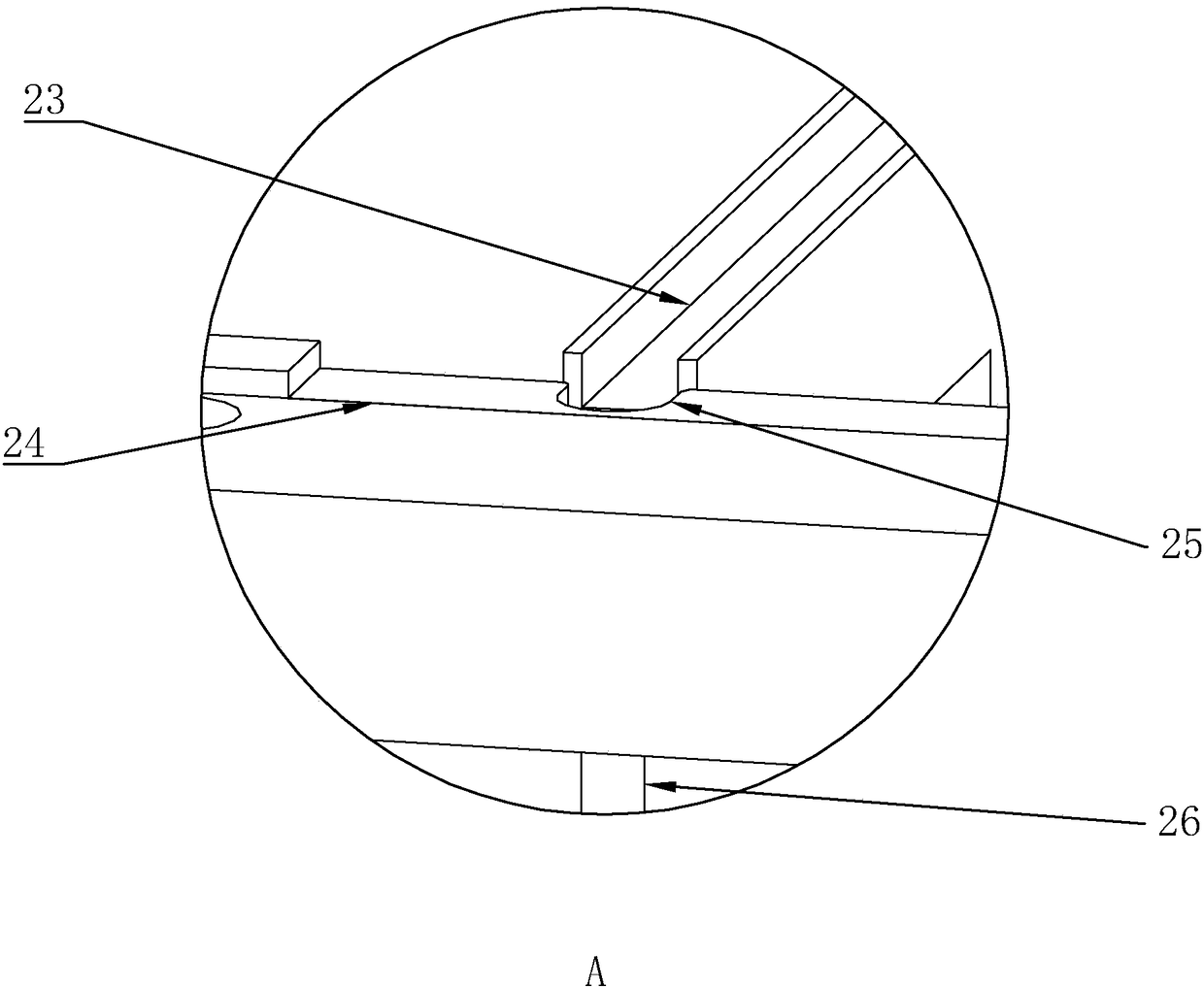

[0042] A fully automatic in-mold implantation machine, see the specific structure figure 1 , including a frame 1, the frame 1 is provided with a feeding device 2 for sorting and feeding the nuts, an arrangement device 3 for arranging the nuts and a delivery material for absorbing and transporting the arranged nuts into the injection molding machine device; the feeding device 2 includes a vibrating plate 21, a feeder 22 and a wrong material mechanism, and the specific structure is referred to figure 2 , the feeder 22 is provided with a horizontal feeding channel 23, and the wrong material mechanism includes a wrong material plate 24, and the specific structure of the wrong material plate 24 is referred to Figure 4 , the wrong material plate 24 is provided with several material holding holes 25, one end of the feeding channel 23 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com