Rolling-free isolating device for wheel

An isolation device, wheel technology, applied in vehicle components, transportation and packaging, vehicle safety arrangements, etc., can solve problems such as misoperation, danger, rolling accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

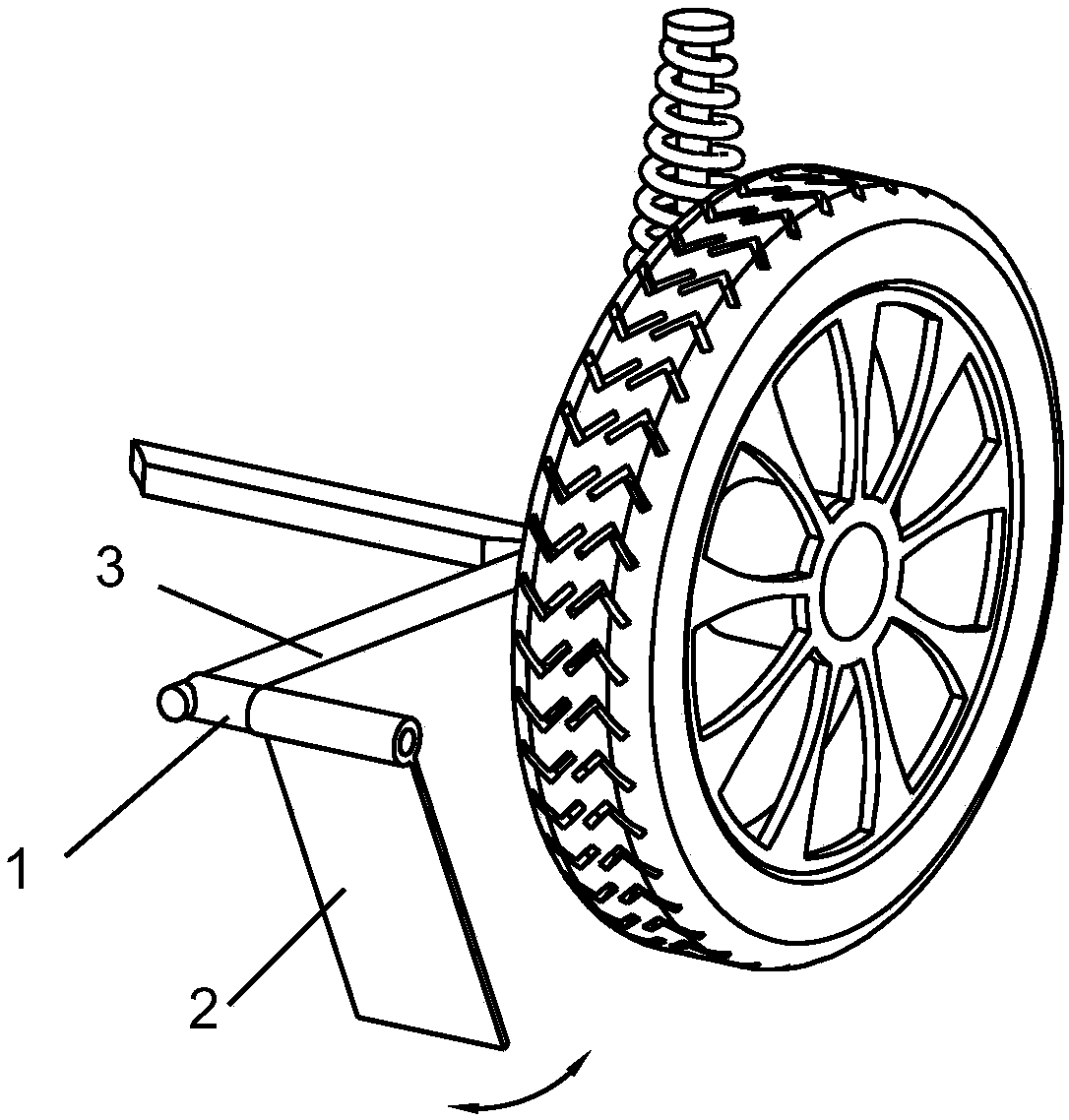

[0023] See figure 1 As shown, in this embodiment, the moving part adopts a pin shaft 1 with a torsion spring, and the blocking part is a rear flip-type baffle plate 2 that is installed on the pin shaft 1 with a torsion spring and can be lifted backwards to open and reset. . Certainly, a plurality of grid grooves can be provided on the baffle plate. Under normal circumstances, when the baffle plate hangs down, some small objects that do not affect normal driving, such as stones, can leak through. At this time, if the force is less than the set value, the baffle will keep blocking to avoid direct contact with the wheel, and the rear lift baffle 2 will push the object forward, which can prevent people and other objects from touching the wheel instantly and the driver cannot respond or not notice it. Cause unavoidable rolling accident, also can add alarm system certainly, after the stopper touches object and does not carry out opening action, send alarm and remind driver to stop...

Embodiment 2

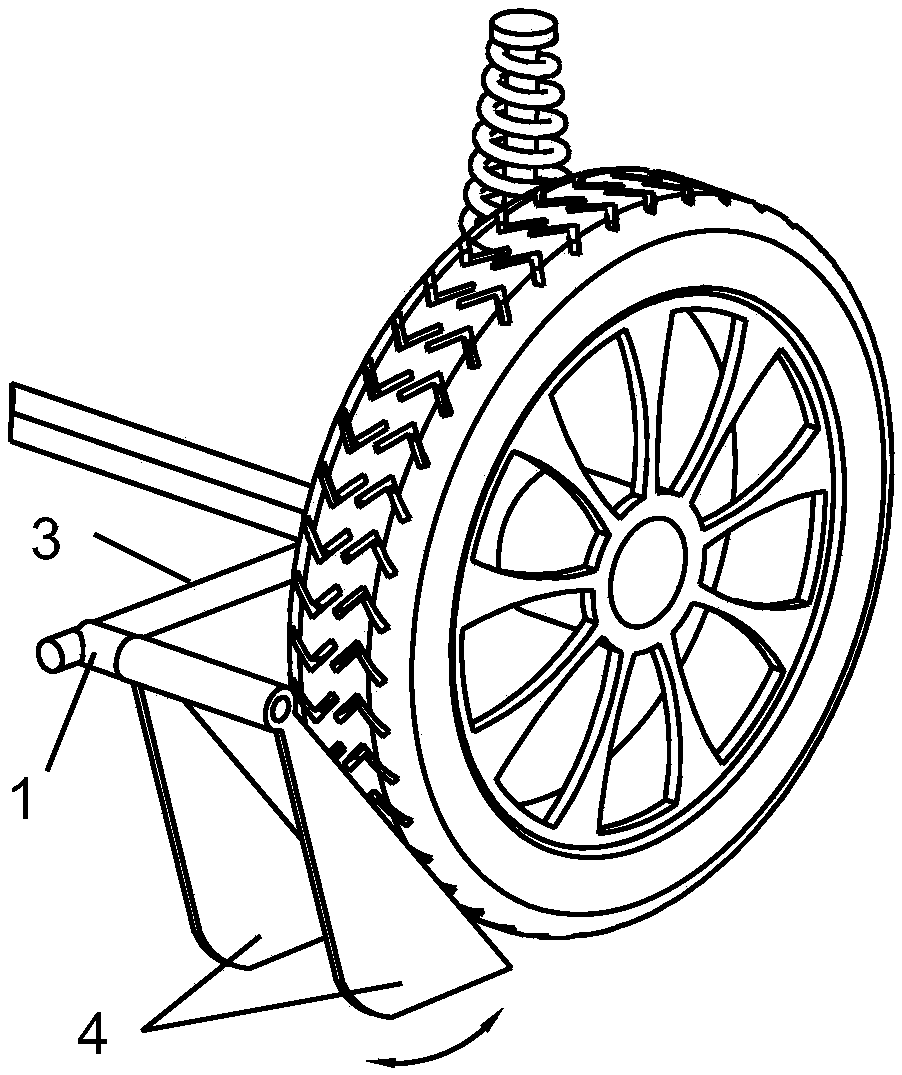

[0025] See figure 2 As shown, the difference between this embodiment and Embodiment 1 is that: the moving part is a pin shaft 1 with a torsion spring, and the blocking part is a pair of straddle wheels that are installed on the pin shaft 1 and can be lifted backwards to open and reset. Side baffles 4, the distance between the two-span wheel-type side baffles 4 is slightly larger than the width of the wheel, when the force is greater than the set value, the two-span wheel-type side baffles 4 are lifted backward and from both sides of the wheel for the wheel Pass by, reset by torsion spring action equally. This embodiment is applicable to the very little car model of wheel front and rear space, is particularly suitable for the steerable front wheel, avoids that object directly contacts with wheel side when turning (see Figure 8 , Figure 9 ).

Embodiment 3

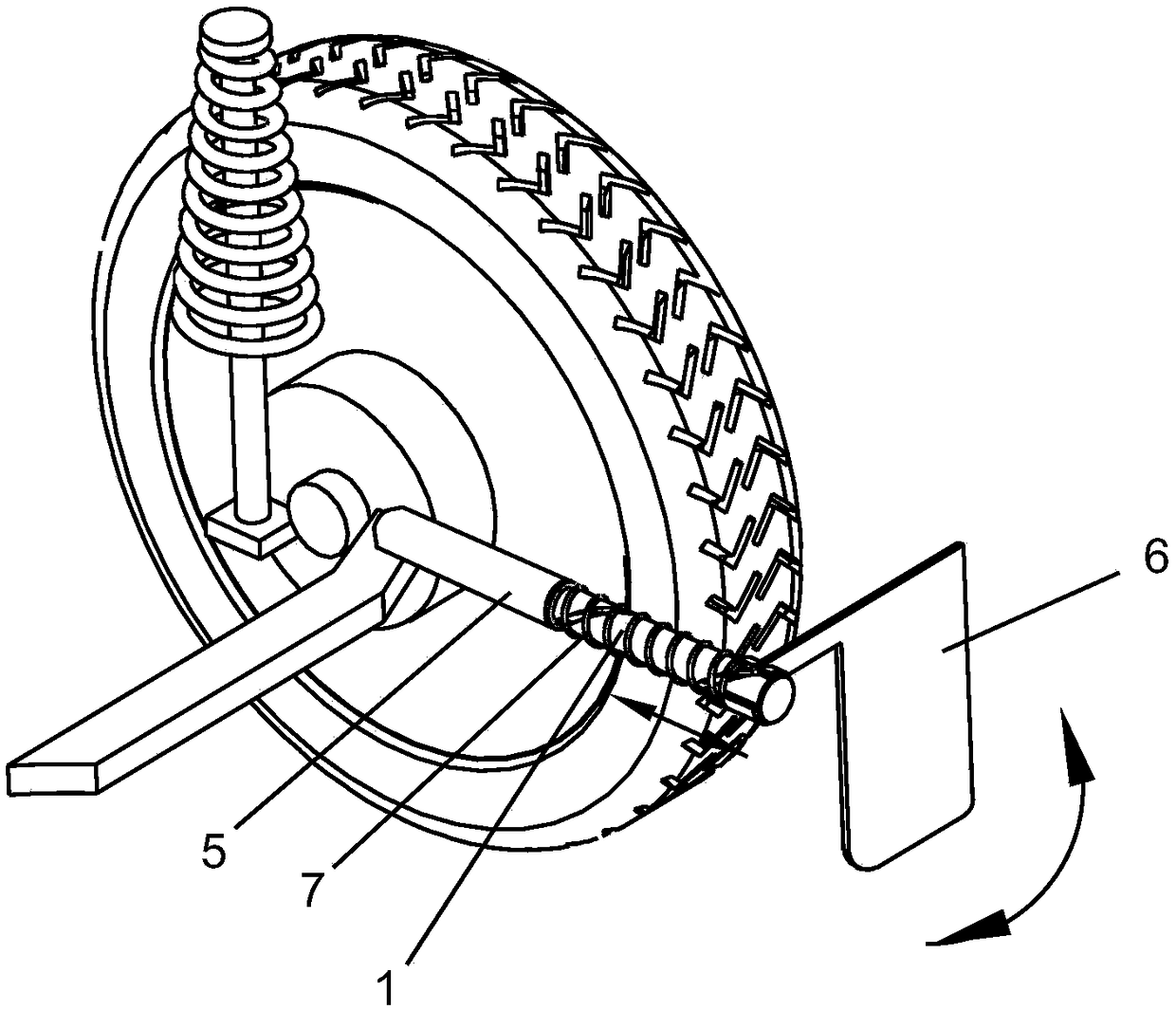

[0027] See image 3 As shown, the difference between this embodiment and Embodiment 1 is that the moving part includes a pin shaft 1 with a torsion spring 7 and a sleeve arranged outside the pin shaft 1, a rotation groove is opened on the sleeve, and the stopper is One end is installed on the pin shaft 1. When the force is greater than the set value, the side-rotating baffle plate 6 can be rotated upwards along the rotation groove to open, and reset by the torsion spring 7. This embodiment is suitable for vehicles with higher chassis and larger chassis space.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com