Substrate processing device

A technology for processing devices and substrates, applied in the direction of workbenches, manufacturing tools, electrical components, etc., can solve the problems of increased installation area, increased costs, and longer production lines, and achieve the effect of suppressing the installation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

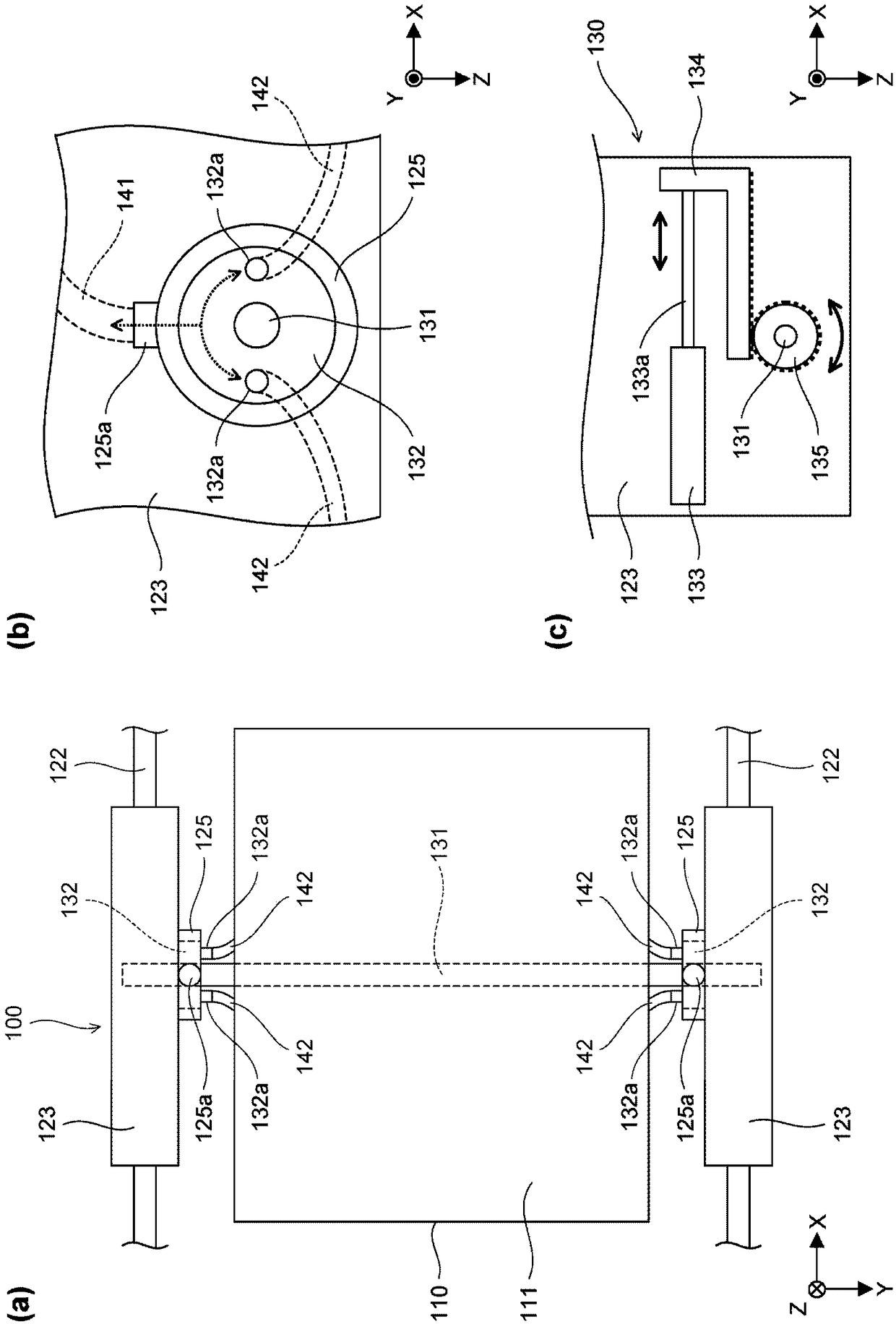

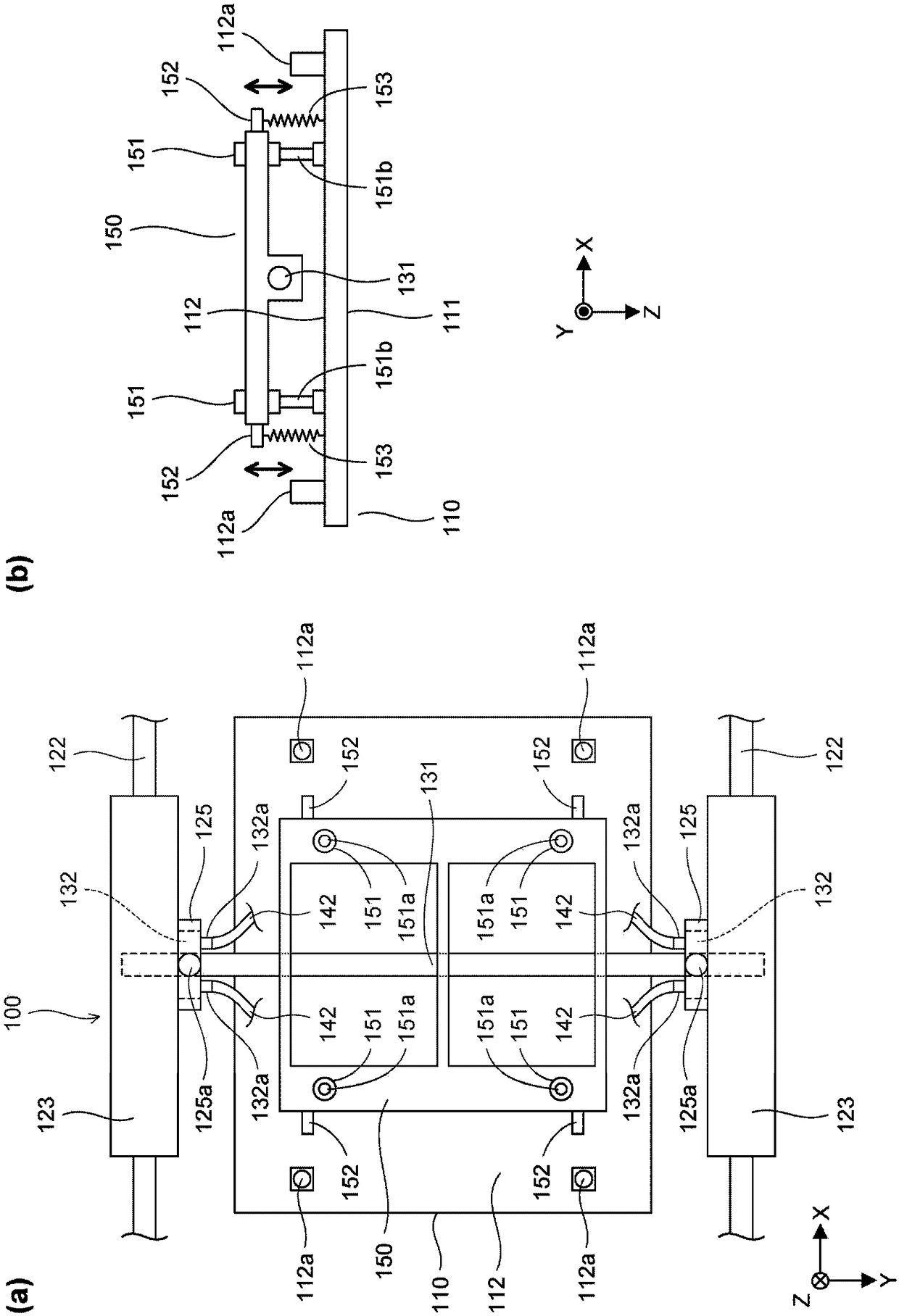

[0051] Hereinafter, embodiments of the present invention will be described with reference to the drawings. In addition, in each drawing, the XYZ axis|shaft orthogonal to each other is shown for convenience. The X-Y plane is parallel to the horizontal plane, and the positive direction of the Z-axis is the vertical direction.

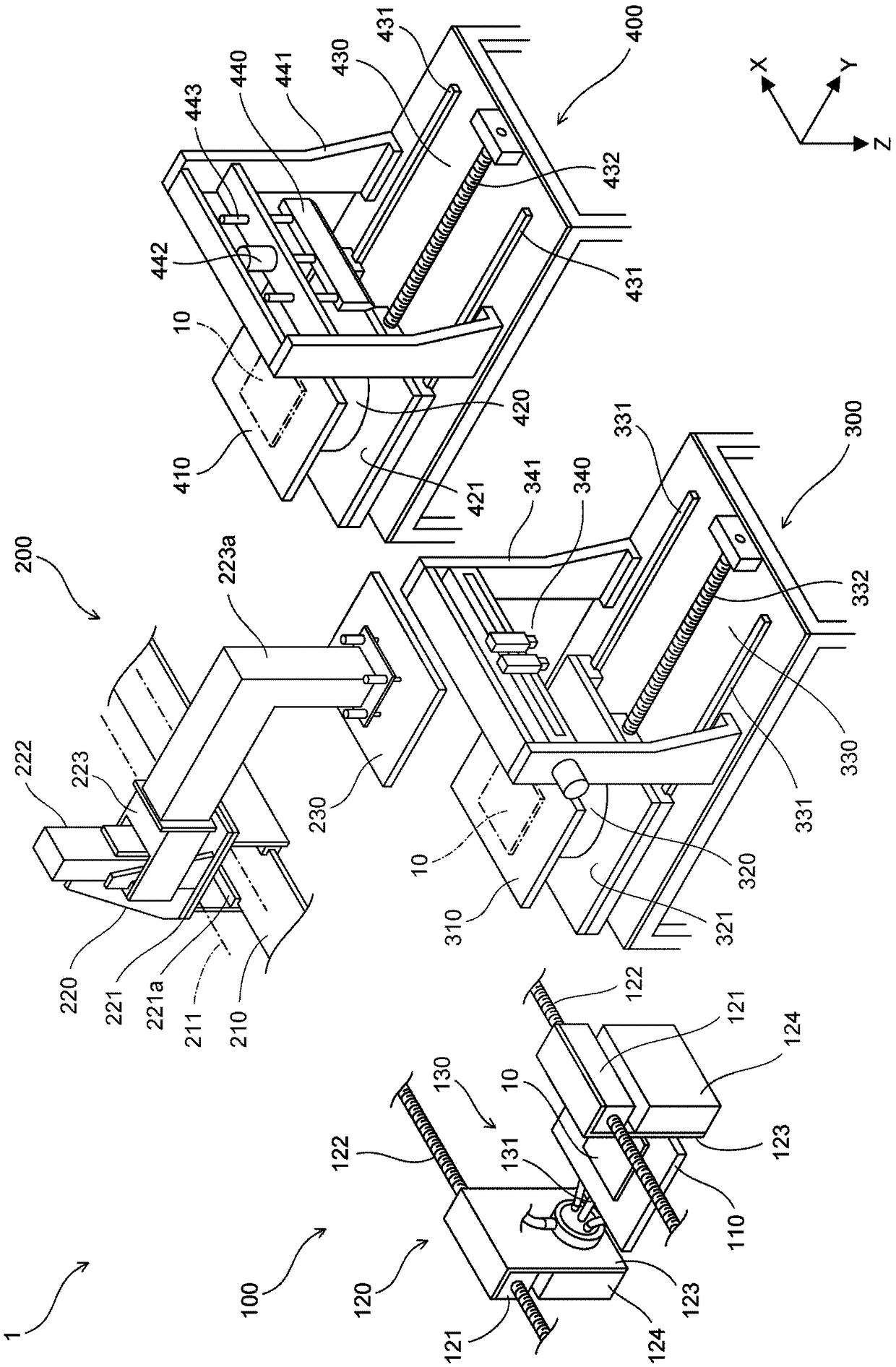

[0052] figure 1 It is a perspective view showing the structure of the substrate processing apparatus 1 .

[0053] The substrate processing apparatus 1 includes a supply unit 100 , a conveyance unit 200 , a scribing unit 300 , and a breaking unit 400 . The supply unit 100 receives the substrate 10 supplied from an upstream device of the substrate processing device 1 . The transfer unit 200 receives the substrate 10 from the supply unit 100 , and delivers the received substrate 10 to the scribing unit 300 and the breaking unit 400 . The scribing unit 300 forms scribe lines on the surface of the substrate 10 . The breaking unit 400 cuts the delivered su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com